Quote:

Originally Posted by DieselJan

The idea of the spring is to keep the conrod length standard except on the power stroke. It will only compress if pressure rises above a set point. Then expand later in the power stroke and put back most of that energy on the crankshaft.

|

Energy, all energy be it electricity, mechanical spring, chemical and so forth shall follow the path of least resistance.

You are attempting to press your spring against nothing, the air in the cylinder will not push the spring more than the camshaft connected to the transmission, connected to the wheels (

the path to applying power to the road).

I think your explanation of delaying or flattening out the peak power as a safety feature for breaking conrods was not your original goal, but a nice try at a save on your part.

Going back to the alternate designs I've brought up and posted, in general they typically have flaws greater than current ICE (

Internal Combustion Engine) technology. Complexity, costs, the ever present laws of thermal dynamics, serviceability, limits on materials, and so forth.

I'm not a huge fan of ICE, on paper they seem to be the least likely technology to have success, and yet here we are 100 years later living with them often as our only choice.

Food for thought:

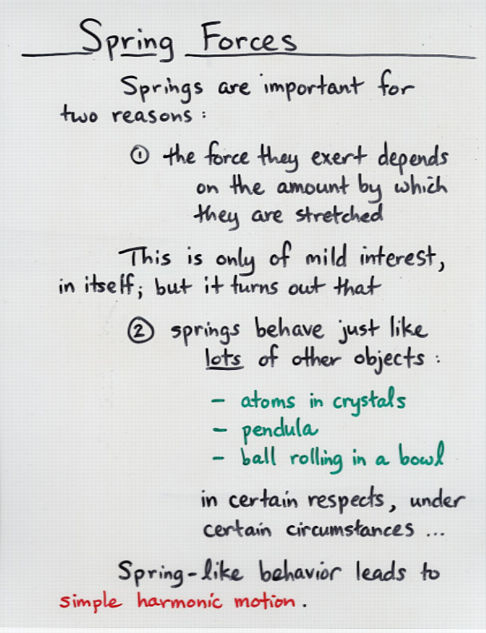

Work by Variable Force, and Spring Force

Quote:

Springs are very important because they serve as simple models for lots of complicated physical systems. Objects which behave like springs behave in a manner which is described as simple harmonic motion; you will see SHM over and over as you continue in physics

The defining character of a spring is that it resists displacement from its rest position with a force which increases linearly:

|

How do springs work? | How do springs store energy?

Quote:

|

Springs are great for storing or absorbing energy. When you use a pushing or pulling force to stretch a spring, you're using a force over a distance so, in physics terms, you're doing work and using energy. The tighter the spring, the harder it is to deform, the more work you have to do, and the more energy you need. The energy you use isn't lost: most of it is stored as potential energy in the spring. Release a stretched spring and you can use it to do work for you. When you wind a mechanical clock or watch, you're storing energy by tightening a spring. As the spring loosens, the energy is slowly released to power the gears inside and turn the hands around the clockface for a day or more. Catapults and crossbows work in a similar way except that they use twists of elastic for their springs instead of coils and spirals of metal.

|

Spring (device)

https://en.wikipedia.org/wiki/Spring_(device)

Quote:

A spring is an elastic object used to store mechanical energy. Springs are usually made out of spring steel. There are a large number of spring designs; in everyday usage the term often refers to coil springs.

When a spring is compressed or stretched from its resting position, it exerts an opposing force approximately proportional to its change in length (this approximation breaks down for larger deflections). The rate or spring constant of a spring is the change in the force it exerts, divided by the change in deflection of the spring. That is, it is the gradient of the force versus deflection curve. An extension or compression spring's rate is expressed in units of force divided by distance, for example lbf/in or N/m. A torsion spring is a spring that works by twisting; when it is twisted about its axis by an angle, it produces a torque proportional to the angle. A torsion spring's rate is in units of torque divided by angle, such as N·m/rad or ft·lbf/degree. The inverse of spring rate is compliance, that is: if a spring has a rate of 10 N/mm, it has a compliance of 0.1 mm/N. The stiffness (or rate) of springs in parallel is additive, as is the compliance of springs in series.

|

Springs are a Steam-Punk technology, they have been replaced in thermostats, automotive suspensions and many other uses for good reason. I would avoid adding more of them to any modern design, more than you have to anyway (

dead weight).