03-16-2017, 12:25 AM

03-16-2017, 12:25 AM

|

#11 (permalink)

|

|

Master EcoModder

Join Date: Jan 2015

Location: Atlanta area

Posts: 410

Thanks: 966

Thanked 74 Times in 63 Posts

|

why not just retard the timing?

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

03-16-2017, 03:41 AM

03-16-2017, 03:41 AM

|

#12 (permalink)

|

|

Master EcoModder

Join Date: Jan 2017

Location: Istanbul

Posts: 1,245

Thanks: 65

Thanked 225 Times in 186 Posts

|

I had a similar idea to yours, well the result is similar but the means are totally different.

I was thinking of using ion sensing ( senses cylinder pressure, Harlan has a few posts on it) and use controlled heated air to speed up the reaction in lean burn (so uncombusted fuel does not escape, burning the valves) and use water injection to slow down combustion so that the power does not spike but is smoother during the stroke. Also adjusting the timing....

|

|

|

|

|

The Following User Says Thank You to teoman For This Useful Post:

|

|

03-16-2017, 04:35 AM

03-16-2017, 04:35 AM

|

#13 (permalink)

|

|

Less waste = better FE

Join Date: Feb 2017

Location: South Africa, Freestate

Posts: 30

Thanks: 9

Thanked 14 Times in 7 Posts

|

Hi Kach22i

Thanks for all the diagrams. I like the camless engine, nice and simple. The flywheel momentum will make it continue in the same direction. The one advantage of the spring is to stop the conrod from breaking. I also don't know what size spring will be needed, but that's why I'm asking.

If you get into the maths behind it, you will find that is the impulse of the combustion that breaks the conrod. That is why people die in accidents and when they fall from the sky. It is not the fall that kills, but the sudden stop.

Craysus:

I am trying to understand how effectively reducing the compression ratio of the combustion chamber, you are "increasing efficiency?"

The idea of the spring is to keep the conrod length standard except on the power stroke. It will only compress if pressure rises above a set point. Then expand later in the power stroke and put back most of that energy on the crankshaft. So its use is to flatten the peak power and make it more useful. The compression ratio will stay the same as the spring will do nothing during compression, only after fuel starts burning and build up enough pressure will the spring compress.

Stovie:

What if you sealed the bottom part of the cylinder and had compressed air push the pistons up will fuel continued to power the downstroke??

Haven't thought about it, could use exhaust gas to push op the piston. But would you get a gain in efficiency.

Mobilone:

why not just retard the timing?

I tried it. On my diesel it just makes white smoke.(un burnt diesel due to low combustion temperatures.) And fuel consumption is bad at high speeds.

I finally sorted out my diesel pump internal pressure and dynamic timing 3 days ago. It's a different pickup now. Will see consumption this weekend.

What we actually need is detonation at about 45-60 degrees ATDC. But at that stage the air temps and pressure is too low for detonation.

So the plan with this mod is to advance the timing to get detonation or very fast and complete combustion close to TDC and then store the energy for use ATDC.

Jan

|

|

|

|

03-16-2017, 08:18 AM

03-16-2017, 08:18 AM

|

#14 (permalink)

|

|

Thalmaturge

Join Date: Mar 2011

Location: The edge of nowhere

Posts: 1,156

Thanks: 763

Thanked 637 Times in 424 Posts

|

Your idea seems to do exactly the opposite of what an Atkinson cycle engine does:

|

|

|

|

03-16-2017, 08:39 AM

03-16-2017, 08:39 AM

|

#15 (permalink)

|

|

Master EcoModder

Join Date: Jul 2011

Location: Ann Arbor, Michigan

Posts: 4,158

Thanks: 120

Thanked 2,790 Times in 1,959 Posts

|

Quote:

Originally Posted by DieselJan

The idea of the spring is to keep the conrod length standard except on the power stroke. It will only compress if pressure rises above a set point. Then expand later in the power stroke and put back most of that energy on the crankshaft.

|

Energy, all energy be it electricity, mechanical spring, chemical and so forth shall follow the path of least resistance.

You are attempting to press your spring against nothing, the air in the cylinder will not push the spring more than the camshaft connected to the transmission, connected to the wheels ( the path to applying power to the road).

I think your explanation of delaying or flattening out the peak power as a safety feature for breaking conrods was not your original goal, but a nice try at a save on your part.

Going back to the alternate designs I've brought up and posted, in general they typically have flaws greater than current ICE ( Internal Combustion Engine) technology. Complexity, costs, the ever present laws of thermal dynamics, serviceability, limits on materials, and so forth.

I'm not a huge fan of ICE, on paper they seem to be the least likely technology to have success, and yet here we are 100 years later living with them often as our only choice.

Food for thought:

Work by Variable Force, and Spring Force

Quote:

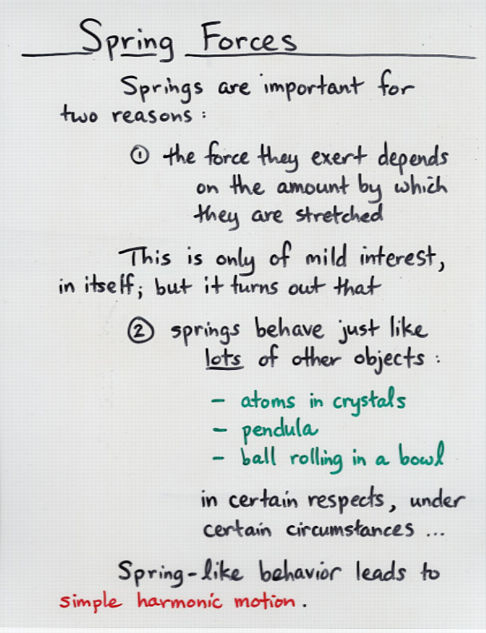

Springs are very important because they serve as simple models for lots of complicated physical systems. Objects which behave like springs behave in a manner which is described as simple harmonic motion; you will see SHM over and over as you continue in physics

The defining character of a spring is that it resists displacement from its rest position with a force which increases linearly:

|

How do springs work? | How do springs store energy?

Quote:

|

Springs are great for storing or absorbing energy. When you use a pushing or pulling force to stretch a spring, you're using a force over a distance so, in physics terms, you're doing work and using energy. The tighter the spring, the harder it is to deform, the more work you have to do, and the more energy you need. The energy you use isn't lost: most of it is stored as potential energy in the spring. Release a stretched spring and you can use it to do work for you. When you wind a mechanical clock or watch, you're storing energy by tightening a spring. As the spring loosens, the energy is slowly released to power the gears inside and turn the hands around the clockface for a day or more. Catapults and crossbows work in a similar way except that they use twists of elastic for their springs instead of coils and spirals of metal.

|

Spring (device)

https://en.wikipedia.org/wiki/Spring_(device)

Quote:

A spring is an elastic object used to store mechanical energy. Springs are usually made out of spring steel. There are a large number of spring designs; in everyday usage the term often refers to coil springs.

When a spring is compressed or stretched from its resting position, it exerts an opposing force approximately proportional to its change in length (this approximation breaks down for larger deflections). The rate or spring constant of a spring is the change in the force it exerts, divided by the change in deflection of the spring. That is, it is the gradient of the force versus deflection curve. An extension or compression spring's rate is expressed in units of force divided by distance, for example lbf/in or N/m. A torsion spring is a spring that works by twisting; when it is twisted about its axis by an angle, it produces a torque proportional to the angle. A torsion spring's rate is in units of torque divided by angle, such as N·m/rad or ft·lbf/degree. The inverse of spring rate is compliance, that is: if a spring has a rate of 10 N/mm, it has a compliance of 0.1 mm/N. The stiffness (or rate) of springs in parallel is additive, as is the compliance of springs in series.

|

Springs are a Steam-Punk technology, they have been replaced in thermostats, automotive suspensions and many other uses for good reason. I would avoid adding more of them to any modern design, more than you have to anyway ( dead weight).

Last edited by kach22i; 03-16-2017 at 08:57 AM..

|

|

|

|

03-16-2017, 10:43 AM

03-16-2017, 10:43 AM

|

#16 (permalink)

|

|

Master EcoModder

Join Date: May 2012

Location: Tampa, FL

Posts: 1,745

Thanks: 206

Thanked 420 Times in 302 Posts

|

I did not read all responses, sorry. I think the most interesting part of this is, could this store some of the combustion energy and release it when it will do the most good, i.e. when the conrod is at or very near to 90deg to the crank.

The two biggest drawbacks would be: can a conrod be designed like this and still be reliable, also, will a spring wear out too fast to be feasible. Perhaps an air "spring".

Yes, heat will be generated bit perhaps it can outweigh those losses by providing more force to the crank when the multiplying effect is the largest (angle).

__________________

|

|

|

|

|

The Following User Says Thank You to ksa8907 For This Useful Post:

|

|

03-16-2017, 10:59 AM

03-16-2017, 10:59 AM

|

#17 (permalink)

|

|

Less waste = better FE

Join Date: Feb 2017

Location: South Africa, Freestate

Posts: 30

Thanks: 9

Thanked 14 Times in 7 Posts

|

Quote:

Originally Posted by ksa8907

I did not read all responses, sorry. I think the most interesting part of this is, could this store some of the combustion energy and release it when it will do the most good, i.e. when the conrod is at or very near to 90deg to the crank.

The two biggest drawbacks would be: can a conrod be designed like this and still be reliable, also, will a spring wear out too fast to be feasible. Perhaps an air "spring".

Yes, heat will be generated bit perhaps it can outweigh those losses by providing more force to the crank when the multiplying effect is the largest (angle).

|

Thank you. I can see you understand the concept.  Yes, that is exactly the idea to release the energy later, maybe not at 90 degrees, but closer to it.

The air spring is an excellent idea, will have to put some thought into it.

Jan |

|

|

|

03-16-2017, 11:27 AM

03-16-2017, 11:27 AM

|

#18 (permalink)

|

|

Less waste = better FE

Join Date: Feb 2017

Location: South Africa, Freestate

Posts: 30

Thanks: 9

Thanked 14 Times in 7 Posts

|

Quote:

Originally Posted by kach22i

Energy, all energy be it electricity, mechanical spring, chemical and so forth shall follow the path of least resistance.

You are attempting to press your spring against nothing, the air in the cylinder will not push the spring more than the camshaft connected to the transmission, connected to the wheels (the path to applying power to the road).

I think your explanation of delaying or flattening out the peak power as a safety feature for breaking conrods was not your original goal, but a nice try at a save on your part.

|

Hi Cach22i

If combustion pressure gets very high, the pressure will not break the conrod trying to turn the engine much faster than it currently is turning. The very high combustion peak pressure will push down on the piston, and the crankshaft will resist it as the engine can't accelerate as fast, so the spring will compress. The spring is not pressing against nothing. Maybe my drawing is a bit unclear.

Go check point 4 in the first post. It wasn't a nice try at a save.

Thanks for all the external links to springs. I confirms what I thought about springs that they don't loose much energy. Also the harmonic oscillations of the spring will be perfect for what is needed.

Your vehicle suspension is some sort of spring system with dampers(shocks) to absorb the harmonic oscillations. I will definitely be keeping mine even if it is stone age technology.

To everyone else:

I am not very interested in different technology engines. Please comment on why this concept won't work or why it could and what can improve. If there is something similar or very relevant please let us know. |

|

|

|

03-16-2017, 11:46 AM

03-16-2017, 11:46 AM

|

#19 (permalink)

|

|

EcoModding Apprentice

Join Date: Oct 2010

Location: Ivins UT

Posts: 213

Thanks: 2

Thanked 22 Times in 20 Posts

|

How about a "magnet" spring??

I think that would allow some simplicity in the design!?! |

|

|

|

|

The Following User Says Thank You to stovie For This Useful Post:

|

|

03-16-2017, 12:56 PM

03-16-2017, 12:56 PM

|

#20 (permalink)

|

|

Master EcoModder

Join Date: May 2012

Location: Tampa, FL

Posts: 1,745

Thanks: 206

Thanked 420 Times in 302 Posts

|

Ideally, assuming this idea can work, i think anticipating the spring compression and then increasing the compression ratio back up to what is common on todays engines could mean big power numbers. You would effectively be getting a longer stroke out of any given engine.

Another effect, as the piston is decelerating toward bdc on the intake stroke, it may also compress the spring at higher engine speeds allowing for a larger effective displacement than static.

...maybe not since the spring would definitely be compressed on tdc.

__________________

Last edited by ksa8907; 03-16-2017 at 01:02 PM..

|

|

|

|

|