ultimately i think many designs are valid, most of the time it will come down to the design of the existing cooling setup and the restrictions thereoff, and the type of actuator you have.

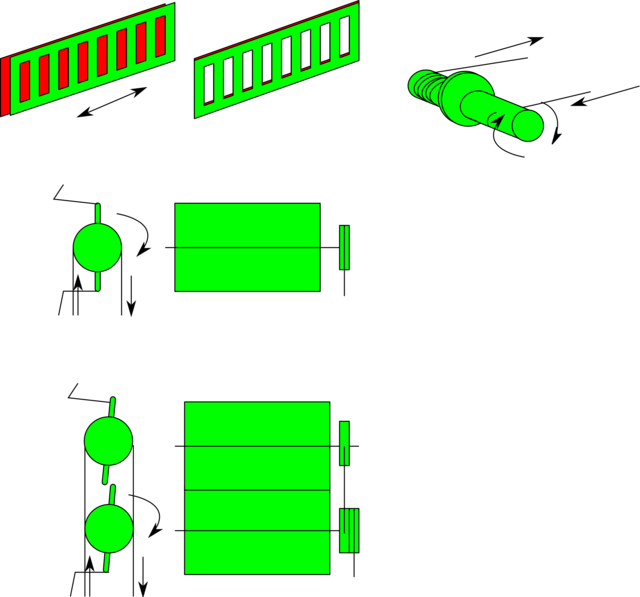

here's some idea's i've been looking into... in my experience rotateing doors are easier to make than slideing ones, but they require a bit more depth, if you're going for a slideing desing a slotted setup as shown below might have some advantages... especially you'd only have to slide the door a fraction of the full distance to make the same opening...thus an actuator with a fixed throw (like the door lock) can be used to provide more torqe, as the same foce has to move the same load over less distanse.

since i was originally planning to use a small motor and gears proved problematic i figured pulleys could work... at first it may look a little mideval, but i figured that if they could put something like that together 700 years ago with simple hand tools, and make it reliable and strong enough to entrust it with lifting a massive wooden bridge that was one of the main safety features of the castle, i should be able to pull off somethign similar that could move a little coroplast rectangle a few cm's... the idea is that two wires are wound around one axle, propperly spaced and maybe separated by a central plate to pervent tangling. useing a relative thin axle it's also an very easy way to convery the fast spinning motion of a relative weak motor into a slow slideing motion with enough torque to get things done

one wire is already wound around the core while the other is just attached to it.

as the core spins the unwinded wire will wind, provideing pulling foce and the othe wire will unwind..this will pull the door open, and if the direction of the motor is reversed it the other wire will pull.

since there's a wheel or lever at the other end the unwindeing wire will be pulled from that end so there shouldn't be to much slack at any time.

i imagine small pulley or running the wire trough flexible tubes could enable the motion to be reliably transmitted over quite some distance, and around curves...

it could be used for both sliding and rotateing doors and in the case of rotating door they can be stacked on top of each other

although i don't think it uses pulleys, the stacked rotary shutter design is currently used on some bmw models