09-17-2012, 03:43 PM

09-17-2012, 03:43 PM

|

#21 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Quote:

Originally Posted by ron

have your bud machine a cup that seals on the oring and fill it with some 5-20 motor oil , that option sounds the best . in the future you may find a use for that extended gear.

|

I already came up with a cap using some 3" hose and a hacked up Peterbilt shock absorber. Pictures to follow. I will probably go with 75W90 gear oil since that is what this bearing bathed in until now.

Today I went to my USA mailbox and picked up my:

1. PB-6 potbox. It will work brilliantly for my purposes. The idle microswitch trips just off idle before the pot resistance starts changing. I will use this microswitch to turn the field power on and off (remember - I'm attempting to power a sepex motor with an Alltrax series/PM controller here!). This safety redundancy will ensure ultimate safety in case my Alltrax decides to weld itself into a closed circuit.

2. 2-400A fuses. One in the high amp wiring, one in the glovebox for backup.

3. Used Volvo vacuum pump. I already hooked it up to the brake booster, gave it 12 volts and pumped the brake pedal repeatedly (and quickly). This vacuum pump easily keeps up, so I will not need to make a vacuum reservoir. And that's good news.

4. Vacuum switch. It will tee into the brake booster vacuum supply and will turn the vacuum pump on and off through a relay.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

09-18-2012, 04:40 AM

09-18-2012, 04:40 AM

|

#22 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Here's the finished bearing end cap. I used a piece of 3" hose, a couple of clamps and I hacked and welded on the outer dust cover off a Peterbilt rear shock absorber. I drilled and tapped it for a plug that will set the oil level in the cap and it can be rotated to adjust the final oil level once installed in the car. I filled it with a couple ounces of 15W40 diesel engine oil. After a few hours nothing leaked out.

My buddy Matt (the machinist) advised me to go with oil instead of grease to lube the end bearing because of the high speeds it will be spinning. Grease would probably just fling out, causing a dry bearing situation. Dry is bad. |

|

|

|

10-04-2012, 12:24 AM

10-04-2012, 12:24 AM

|

#23 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

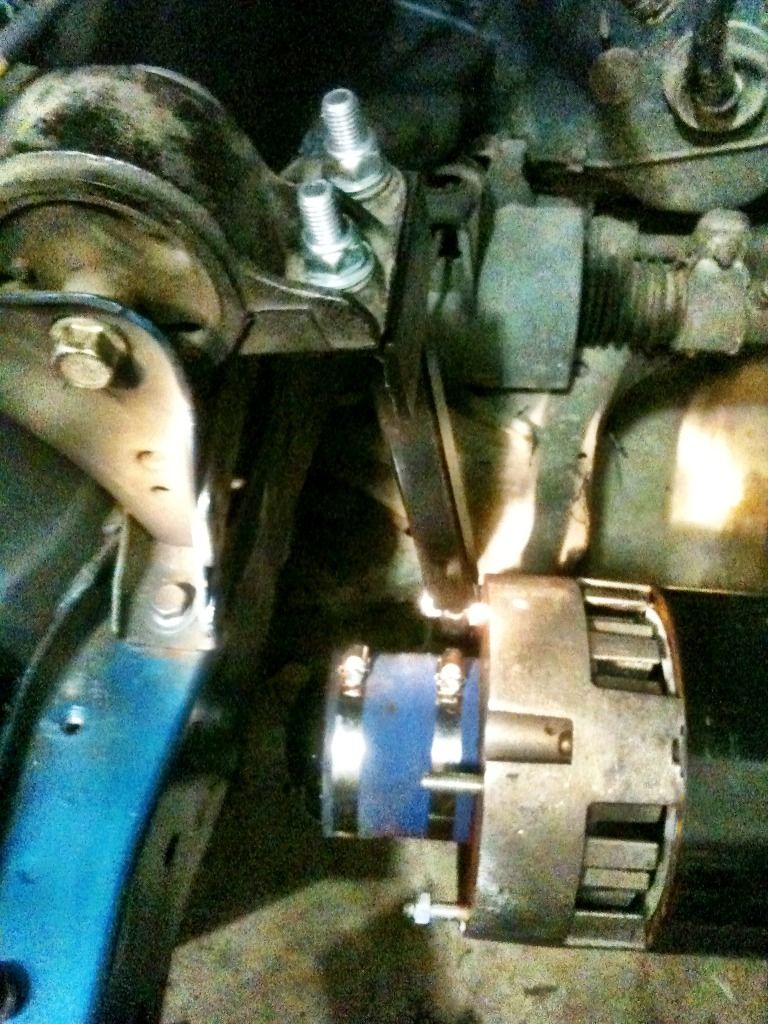

The motor and transmission are installed and ready to go.

I had to fabricate a mount for the passenger side end of the motor to keep the engine/transmission angled correctly.

I also completed the front battery racks. I made them out of 1" angle iron and 1/2" square tubing.

Here are the five group 31 underhood batteries installed for fitting purposes. I am pleased to announce that they fit beautifully!

I am going to run ATF in the transaxle. The manual specifies ATF only for ultra low temperature climates, but considering this motor will not have much power, I'm not worried. The thin ATF should help with reducing driveline friction a tiny bit. |

|

|

|

10-04-2012, 09:50 AM

10-04-2012, 09:50 AM

|

#24 (permalink)

|

|

Administrator

Join Date: Dec 2007

Location: Germantown, WI

Posts: 11,203

Thanks: 2,501

Thanked 2,585 Times in 1,553 Posts

|

Quote:

Originally Posted by mechman600

I am going to run ATF in the transaxle. The manual specifies ATF only for ultra low temperature climates, but considering this motor will not have much power, I'm not worried. The thin ATF should help with reducing driveline friction a tiny bit.

|

You might not have massive amounts of power, but you will have fairly decent torque. 450A on a 6.5" motor is going to give you around 70 ft/lbs which is about 70% of what the stock engine had. I'd recommend going with what the mfg recommends. You aren't going to loose much by staying with a thicker oil. |

|

|

|

10-06-2012, 04:23 PM

10-06-2012, 04:23 PM

|

#25 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Thanks for the advice, Doax. I agree with you on all things except the 70% of ICE torque one. There's no way the 1.5 had 100 ft/lbs! Probably more like 70-80. Therefore, your advice holds even more truth.

However, I have a bunch of ATF laying around, so I am using it temporarily for low speed testing and whatnot. Simply put, I was in a massive hurry to test this thing out and didn't feel like running to the store to buy gear oil! Here's a video:

I have also completed the rear battery rack:

That's right, no more back seat. My choices were to keep the useful trunk and use the useless back seat for batteries or keep the useless back seat and use the useful truck for batteries. It was an easy decision.

Next the control system and battery cables. Test drives by next week? |

|

|

|

10-08-2012, 02:10 AM

10-08-2012, 02:10 AM

|

#26 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Here's the pile of batteries installed in the rear battery rack:

The old girl is a little saggy in the back now with 480 lbs of lead in the back seat. It took about 45 psi of air in the rear tires to get rid of the bulges. Corvair style.

I also think I figured out my heater situation. I was going to replace the heater core with a ceramic element from a 110V heater, but I soon realized that removing the heater core in this car is a huge pain in the butt. However, I discovered that the heater fan is on the passenger side and connects to the heater box with a plastic pipe that can be removed in about 10 seconds:

There is a 1875 watt hair blow dryer on sale at Canadian Tire for $10 right now, and I think I will be able to dissect it and stuff it into this pipe, minus fan, powered by my entire pack voltage. It won't know the difference between AC and DC will it?

And to continue the eternal EV conversion gag of installing the charging plug in the ex-gas cap:

|

|

|

|

10-08-2012, 11:08 PM

10-08-2012, 11:08 PM

|

#27 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

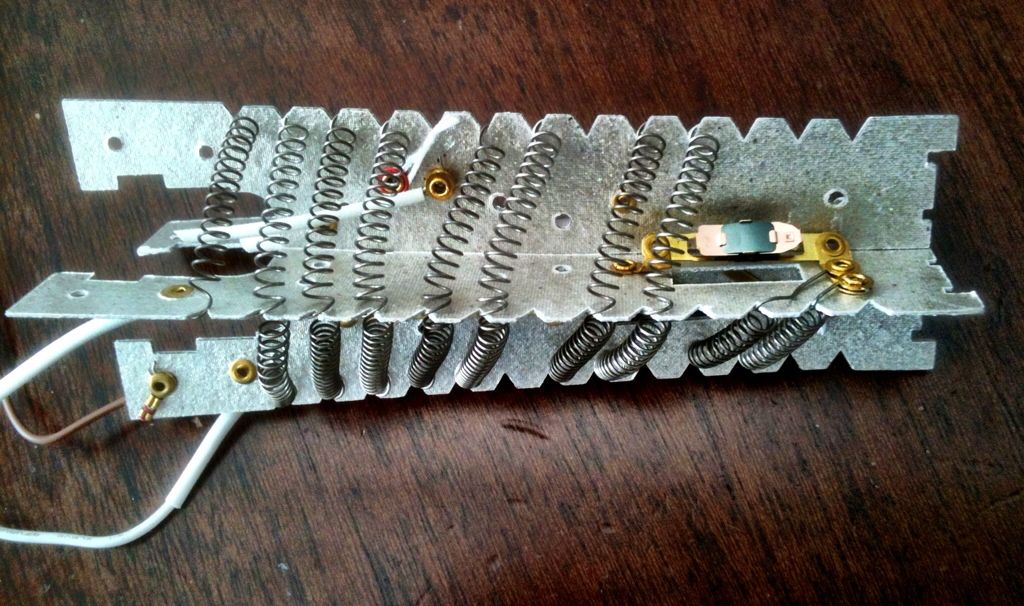

Today I went out and bought the $10 blow dryer. I dissected it to get the heating coils out of it. Built into the coils is a bimetallic temp control switch and a thermal fuse for safety.

I mounted it into the plastic tube connecting the heater fan and heater box.

For a test, I turned the heater fan on and plugged the blow dryer coils into 120VAC. In a matter of seconds, the Booger's heater was blasting heat much better than it ever has (not a huge feat considering the coolant thermostat was stuck open ever since I owned it). I ran the heater for about 10 minutes. No funny smells, burning, melting or fire. I pulled it apart to make sure and all is well. It looks like the solution for heat was quick, cheap and painless after all! |

|

|

|

10-14-2012, 12:03 PM

10-14-2012, 12:03 PM

|

#28 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

It's ALIVE!

Lots of updates to catch up on.

1. Traction wiring is finished. I was able to find enough used 4/0 truck battery cable to do the job. Overkill, but awesome.

2. Control system wiring is finished. I am powering the field windings with 12/24V with a toggle switch on the gearshift (through a relay, of course). I am also using the potbox idle switch to turn the field power on only when the go pedal is pushed. I was able to find a decent sized diode to wire between the field terminals to eliminate the massive spark that occurred every time I turned the field power off.

3. The six Mastercraft 10/2A battery chargers are installed.

The first test drive was a fail. I remember watching a Ben Nelson video when he was trying his electric motorcycle for the first time and it went backwards. So I guess you can say I "pulled a Ben Nelson" on my first attempt. (Sorry, Ben). I put it in reverse to back off the ramps and the car lurched forward. So I backed off the ramps in first gear. Hmm....one forward gear and five reverse gears - that won't work. It turns out that I had mixed my field polarity up, and thankfully didn't blow up my field spike suppression diode.

Test drive #2 happened last night. It was a very short one around my townhouse complex, getting up to a whopping 20 km/h, but I did experience a massive "EV grin" that took hours to subside. My initial thoughts are that I believe I have succeeded in powering a sepex motor with a series/PM controller.

More updates/pictures/video to follow. Hopefully soon.

Here's my insurance papers now:

The lady at the insurance place was nice enough to change the fuel type for me.

Last edited by mechman600; 10-14-2012 at 04:26 PM..

|

|

|

|

10-15-2012, 01:26 AM

10-15-2012, 01:26 AM

|

#29 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

Today I was running power wires for my heater when I suddenly got a highly unexpected 72 volt shock. My ratchet was on a contactor lead and my elbow was touching a chassis bolt.

WHAT??

I thought I had very carefully isolated the traction wiring from the chassis... My multimeter showed a 72V difference between the chassis and traction positive. After a few moments of scratching my head, I decided to unplug the system voltage meter I installed last night and recheck. Once I did, there was no more voltage reading between chassis and traction pos. So my $8 four wire volt meter is not isolated and eventually will have to be chucked for something different.

Or is it something I should even worry about?

|

|

|

|

10-15-2012, 04:00 AM

10-15-2012, 04:00 AM

|

#30 (permalink)

|

|

Master EcoModder

Join Date: Jul 2008

Location: Langley, BC

Posts: 1,228

Fusion - '16 Ford Fusion Hybrid SE

Thanks: 190

Thanked 275 Times in 168 Posts

|

I just got back from a fairly lengthy test drive. I am blown away by how well my electric car works. Yes, I can officially say those words out loud - "my electric car". I was actually nervous about going out with it. Would it break? Leave me stranded? Catch on fire?

I left the field voltage switched to 12V the entire time. I found that on 24V, the field relay got smoking hot and started making hissing noises. I have never heard a relay make hissing noises before, but I know that's a bad thing. I believe it is a high current problem, not a higher than-designed-for voltage problem.

In most EV conversions, you usually start off in second gear. But I found second gear far too weak, so I got used to taking off in first and switching to second at about 30 km/h. It seemed to top out at 60 km/h in second and I didn't bother with third because of lack of space, but I am confident that it will easily exceed my goal of 70 km/h.

After one lap around the block I started to get confident, so I kept driving around and around, turning here and there. I probably drove a total of 10 minutes, and not with economy in mind. When I got back to my garage, the system voltage still read 73.6 volts, which means I hardly put a dent in the battery capacity. So I have a feeling that my 20 km range goal might be a possibility.

The power brakes work amazing. There was no difference between being powered by a Volvo vacuum pump and being powered by vacuum from the old ICE.

How quickly does it accelerate? Not very quickly, but it accelerates and that's all that matters. You have to realize it is now a 3200 lb car with about 25 horsepower (on a good day).

When I got back to the garage I quickly opened the hood and checked to see how hot the motor is. Remember that I have a very small motor here and I am asking it to do a lot. The motor was definitely warm, but I could easily hold my hand on it, so things are looking good there too.

Stay tuned for more pictures and video in the next while. Now I just can't wait to drive it again!

|

|

|

|

|

The Following 2 Users Say Thank You to mechman600 For This Useful Post:

|

|

|