Longish post follows.

I am a boat builder/wood worker, but from time to time I get involved with

working sheet plastics, mostly for instrument panels, small windows, etc.

So,I have some limited experience here.

What you've shown is typically called a "wing cutter." I would be reluctant to

use it, especially where a smooth, finish is desired on the cut edge. The

difficulty with the wing cutter is that almost inevitably as the cutter gets to

the bottom of the hole it "breaks through" and then twists/tears/breaks the

hole edge somewhere along the circumference. Damn!

In general, it is recommended that holes in Plexiglas at any rate be made

with a course toothed hole saw in a sturdy drill press. Typically something

like this:

They are available in sizes from ~1/2 inch up to :

(If that saw catches on something and stalls, the operator is risking one

or even two sprained wrists.

For uses like this the drill motor should

have two directly opposed handles on the sides of the drill body.)

The hole will be somewhat ragged, showing tooling marks from the drill's

teeth. To get a really smooth, finished look/feel, I have heard that you first

cut a slightly undersized hole with a hole saw, and the re-cut the hole to

desired/final size with a router with a spiral cutter. Something like this,

where the amount of material to be removed, ~1/8 in., 3 mm, is less than

the diameter of the cutter:

You'll need to make custom sized jigs for each hole size to be made

The router doesn't have to that powerful, a laminate cutter or RotoTool

should do fine:

For a more formal discussion of these matters from pro's, here's a good

place to start, See especially the PDF download at the end:

How to Fabricate Plexiglass - cutting plexiglass from ePlastics.com

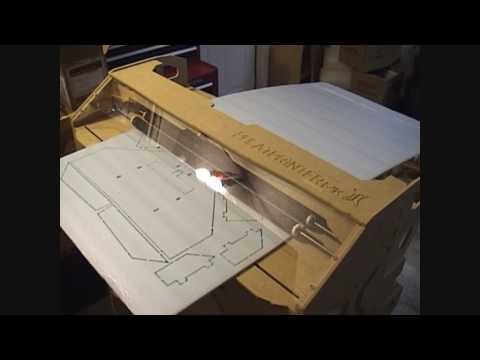

[EDIT] You may also want to consider a small CNC machine to do this.

Here's one that is designed solely for sheet goods that comes as a kit

for ~$1000 USD. It may not be quite wide enough for what you need :

(I'd kill for one of these!)

Phlatprinter 3 Kit

Best of luck to you.