I notice that you are direct driving the drive shaft without the gear box. How are you placing the motor? Off to one side or are you centralising it somehow?

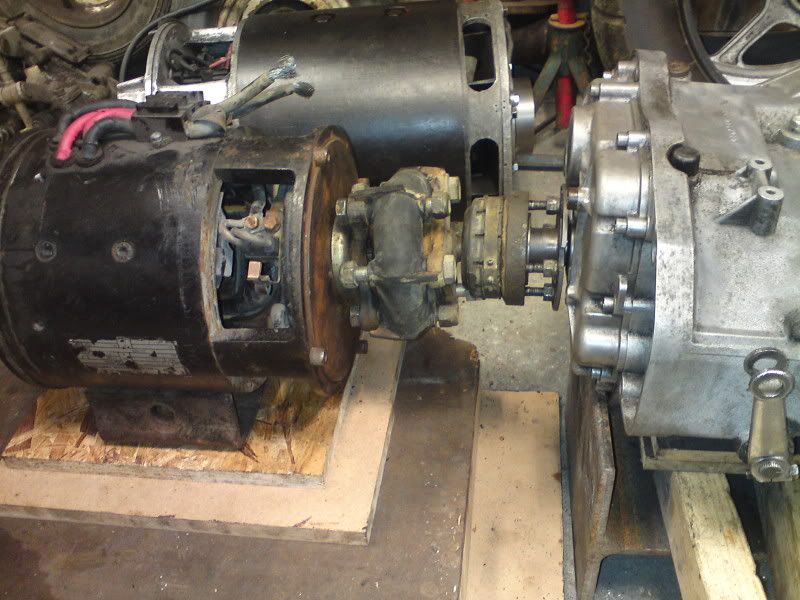

I am building a reverse trike using a BMW K100 transmission complete.

The input shaft is 90mm off centre but the shaft would be 150mm off centre and higher then my prefered motor mount. I am going to use a short shaft but a nice looking one.

The trans gives me a slightly under geared drive for what I wanted, 1.61:1 top gear with a 2.81:1 final drive giving 4.52:1, for my first choice 12" motor so I have decided to use a smaller but hopefully faster 9" motor.

Those shafts look great, though costly!

I was using a similar motor but not having access to anything but a small lathe I had to find a simpler way to make splines.

Turned a blank on the lathe.

Marked out the edges of the splines.

Cut the splines with a 4 1/2" disc cutter freehand.

Fits a treat. (notice the wooden DE bearing cap)

I made three of them in the process of working out how to use the other end.

I settled on this one with a support bearing on the outer end.

I even had to chisel the keyway out with a small cold chisel.

I also used a square of aluminium plate for the DE.

It now drives my tractor.