Neil,

Perhaps I can help with some of the matters you've raised lately.

Unless you're dealing with a small hobby shop or similar concern, virtually

every one buys "Sheet goods," ie, plywood in 4'x8' or 5'x10' sheets. They

then cut it up into smaller pieces for resale on a panel saw. At Home Despot,

Lowes, etc, ask for the wood products area manager(?) and ask about buying

an uncut sheet.

For the very highest quality plywood required by the FAA in "experimental,"

ie, home-built aircraft try these folks, be sure to check out their composites

section too:

Plywood from Aircraft Spruce

For spanning large flat areas, you might want to consider "composite panels."

Typically they are aluminum skins over honey comb or high density foam.

Very rigid, very light. Can also be done with ply skins. Best to do your own

Googling on this.

Quote:

Originally Posted by NeilBlanchard

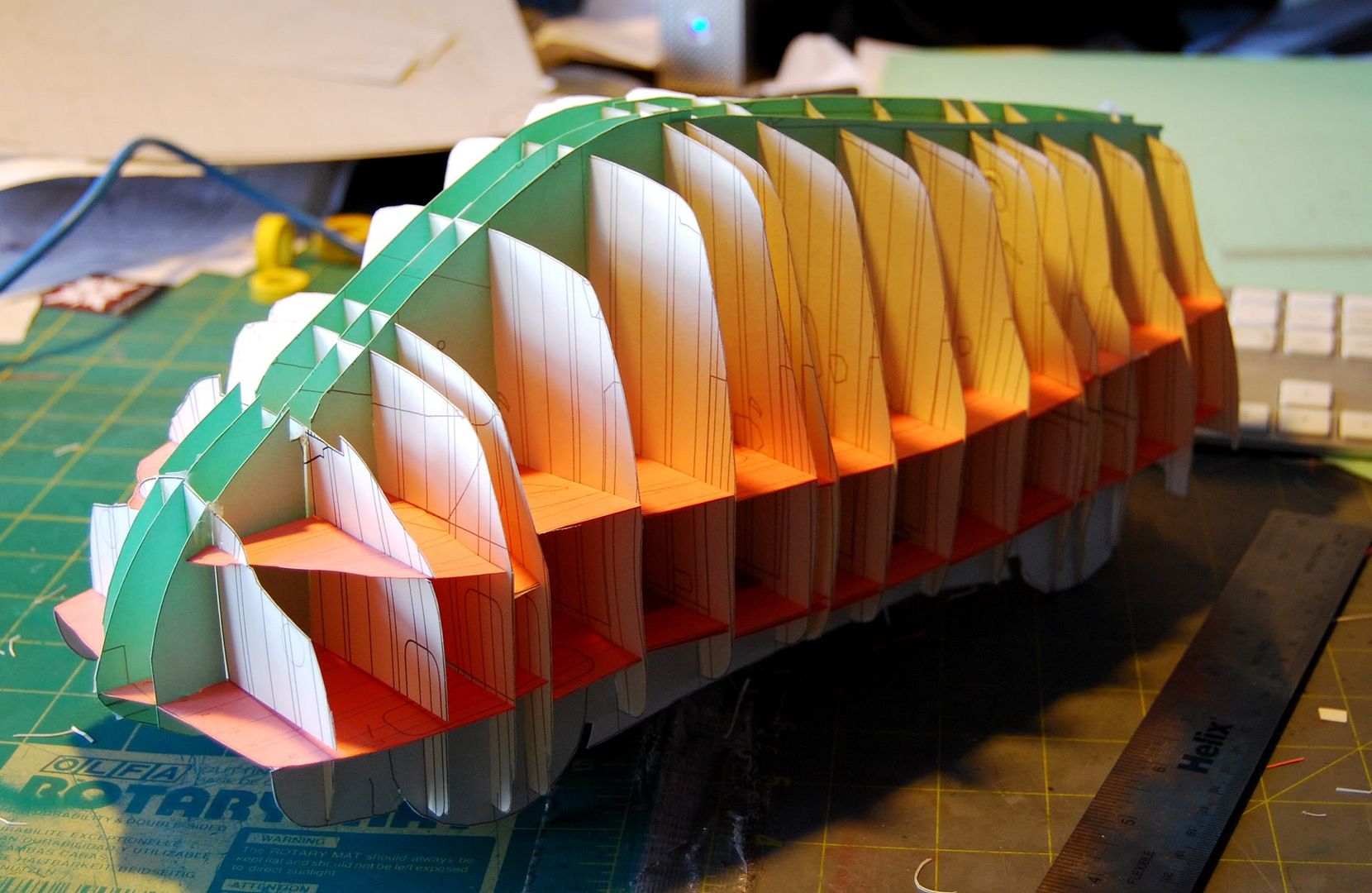

Here's the 1:12 model in process:

|

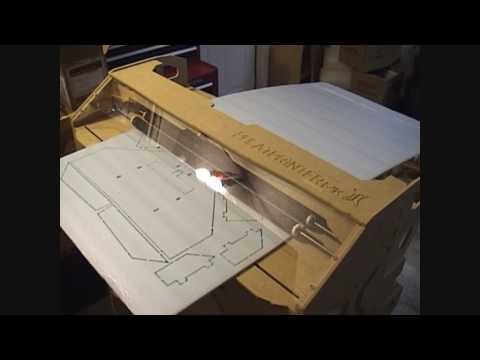

Whether it's a 1:5 scale or full size, part accuracy is going to make or break

the effort. I'm thinking a relatively inexpensive 2-axis CNC machine is what

you'll be needing. Here's one made specifically for sheet goods, comes as a

kit for ~$1000 USD. Perhaps most importantly, it will cut directly from

Sketch Up files:

I think the kit parts are made on one of these mahines.

Phlatprinter 3 Kit