After getting the measurements, I planned on making a solid base for the extension out of round steel tubing( free) and supports our of thin steel flat bar and and round stock( cheap or free). I was going to use cardboard and fiberglass resin for the skin, but further reading of MetroMPGs thread said that he was having issues with moisture bubbling before he removed his. A friend at work had used cloth fabric, chicken wire( for shaping) and resin for builds, followed by body filler( Bondo, if you will) for final smoothing. Sounded like a plan to me. I grabbed the welder and set to work.

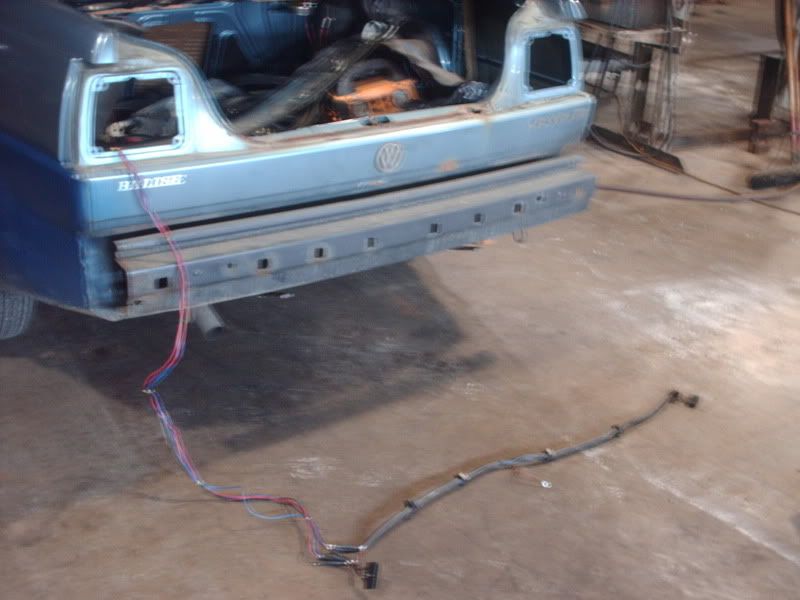

Rear window and trunk removed( sorry for the blurry pics, it was dark in the shop, flash only lit near objects, and when I turned off the flash to lighten the pics, I couldn't hold the camera steady enough, which I couldn't tell viewing them on the camera, found out while downloading them

).

Wiring harness already extended and run through( temporarily) the old light opening.

First loop welded to the body of the car.( Sorry, again)

The full frame welded in place. The rod down the center is just a place marker for measuring angles at different percentages of template.