Quote:

Originally Posted by Sven7

rainagain, if you make one more post you should be able to go back and edit in the photos

Anyway Perhaps you thread a carriage bolt in there to hold it in place?

I'm guessing Fife is Fife - Wikipedia, the free encyclopedia |

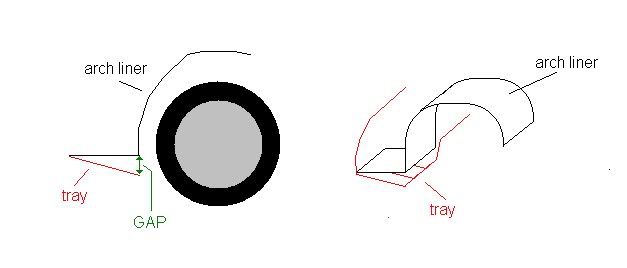

Looks like both approaches might be right. Use Foam to fill the gap, then use a bolt to the fender liner to stabalize the whole package, without putting "much" stress on the liner. As you suggested use some Saran wrap to keep the foam from sticking to the fender liner. Put the bolt through some plastic tube, like a large soda straw, to make a "drilling" through the foam.

Btw, you can trim the foam after it has cured and you can always apply a bit more if needed. Just remember that this foam expands considerably as it cures, so err on the side of too little until you get a feel for the expansion rate. Start at the "thin" edge and work bakward to the wide edge. I think I'd plan on small multiple applications until I got a feel for how the expansion works. You will want to use somethng to hold the pan up, because the foam expansion will try to push it down. You may want to lay a brick on the wheel liner flat portion to hold it down. With those two measures, the foam expansion will be channeled into the gap.Be sure to get a good layer of Saran wrap on one of the surfaces.

It is a good looking undertray and your installation looks professional. Just your good luck to find it