Quote:

Originally Posted by AndrewJ

...ABS seems to me to be the ideal material for making fairings and such because of it's malleability under heat and because it can be "welded" with the right equipment... |

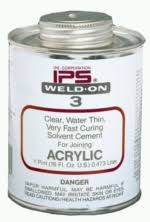

sorry to threadjack... back in OP, ABS welding was mentioned... We use "weldon 3" in a syringe bottle all the time for ABS. A chemical welding. no heat, miniscule color deviation along seam. kind of a 'squeezed out' look if you apply too much. You can weld other ABS straps, band-aids, or tapping thickness on back too. Apply it sort of like you would superglue... not too much, but enough on both seams. Fully cured, it always holds fine for me...

Careful of an uncapped needle! Excess fluid will cause a melt drip or fingerprints. It evaporates pretty fast too, so I always empty syringe back in can.

Just my $0.02