In the past, it took several fill coats and sanding or expensive vacuum bagging gear to get a smooth layup.

The "drier" you can lay up glass, the stronger it is by weight. The trouble comes when you want a smooth finish. If you sand a typical dry layup, you will sand right into the glass itself. The old solution is to add as many fill coats as necessary to cover the glass and get a sandable margin.

Recently I found this simple method to get quick results.

Lay up your glass as you normally do, them apply a film of 10 mil mylar or similar plastic over the wet epoxy, squeegee out any air bubbles and excess resin, and let cure.

Once cured you can peel off the mylar.

What the film does is compact the layup, squeeze out excess resin, and leave a surface as smooth as the mylar itself.

I have not done any large areas yet, since my current project involves only resin coating with no glass.

I used 4 once E-glass over some scraps of virola marine plywood. 4 ounce is about as heavy as you can go and achieve a transparent layup over wood.

Wet layup:

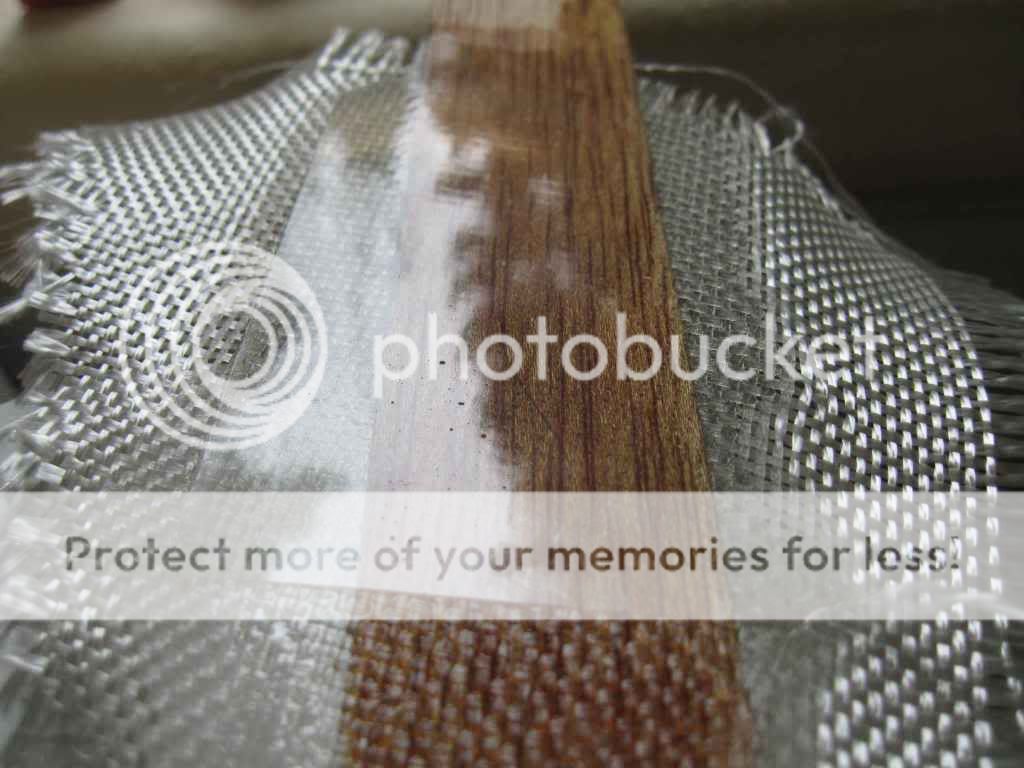

Mylar placed over one section of glass:

Air and excess squeezed out with plastic squeegee:

results from previous sample. Part of the sample was left as usual with the fabric weave showing.

That is a reflection of the trees in our yard out the window.

Another view:

This was junk resin. You can see some small bubbles in the otherwise glass smooth surface. I think those were from the foam in the resin, I literally wrung out the paint roller to get some resin to make this sample. it was frothy white in the cup.

What you can do with it:

Bend over large radii.

What you can't do with it:

lay over a compound curve in a single piece. It will not warp in two directions.

The answer is to use strips and butt them together. This will form some small raised seams in the finish. You can cut those off with fine grit paper.

This is where I found it:

A new Technique for Epoxy-Glass

I figure this could be handy for building aeroshells, etc.