Yes.

The amount of fuel injected at any moment is dependent on many factors but the 2 main ones are RPM and engine load. Engine load is defined as a percentage of the maximum amount of air the engine can breathe at a fixed RPM (wide open throttle). When you hit the gas at 3000RPM the injector pulse width will increase instantaneously before there is an appreciable change in RPM.

Engine load can be detected several different ways. The most common on modern EFI engines is a MAF (mass air flow)sensor which is solid state can tell how much air is passing through a fixed diameter hole. An older version of this was a trap door AFM (air fuel meter) which used a spring loaded door in the intake to sense how much air is flowing through the intake. Both of these sensors are before the throttle plate A third method is to measure the vacuum level inside the intake manifold after the throttle plate.

MAF

Trap door AFM

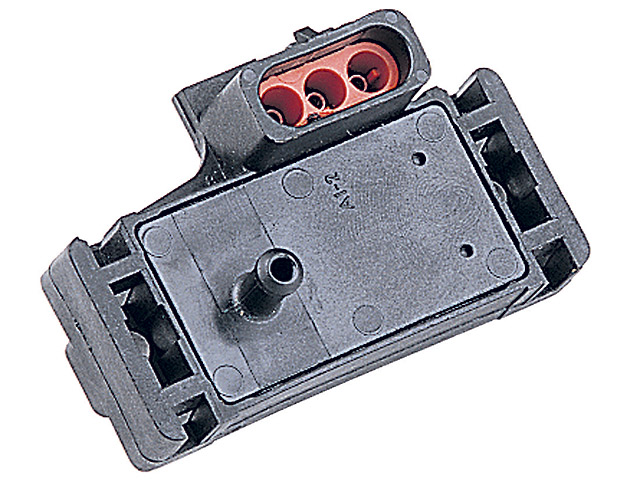

MAP sensor. This one is usually very small and some times its mounted remotely away from the engine via a small vacuum hose. This sensor can measure both vacuum and boost. Some engines (especially turbo or supercharged) use a combination of MAP and MAF to calculate load.

A rare few cars (mostly off highway race engines) rely only on a TPS (throttle position sensor) to calculate load. This method sacrifices smooth idle, part load drivability and fuel economy in favor of incredibly quick throttle response and peak power. Most street cars also have a TPS but its used for acceleration enrichment rather than outright load. AE is only needed for a split second between the moment you hit the gas and the moment your MAF or AFM detects a change in load. Its also useful for idle control, cruise control and warm up phase of the drive cycle.

The typical TPS based race engine lacks a manifold or a common intake to determine load.