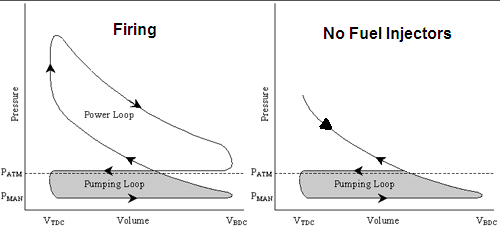

The above diagram shows an engine cylinder pressure/volume diagram, showing the amount of work needed and the amount of work generated in that cylinder. The power loop area represents the amount of work generated in the cylinder. The pumping loop area represents the amount of work being taken away from the cylinder, basically in order to maintain an intake vacuum. There's more work being taken away than that, but this pumping loop area is directly related to cylinder output.

Now, take away the power loop area, such as with removing fuel from the cylinder by cutting out a fuel injector (like DCD does), and you still have pumping work to consider. The deactivated cylinder is still pumping air through itself. On a 4-banger pushing a car forward at a given constant speed, the remaining 3 cylinders are doing the same pumping work as the deactivated cylinder. However, the remaining 3 cylinders also have to produce the same amount of power as before. They also have to produce the power that the deactivated cylinder would have made, had it not been starved of fuel. This is so that the 4-banger can still push the car forward at that same given speed, and cover the pumping work that the deactivated cylinder is consuming.

Since DCD only cuts out a cylinder once per firing cycle, intake manifold vacuum never gets a chance to significantly lower, which would otherwise lessen the amount of pumping work needed by the 4-banger. At best, there is no noticeable gain in fuel economy. In real-world conditions, the OBD-II engine computer would notice the misfires being induced by DCD, and would throw the engine into a less-efficient limp-in mode.

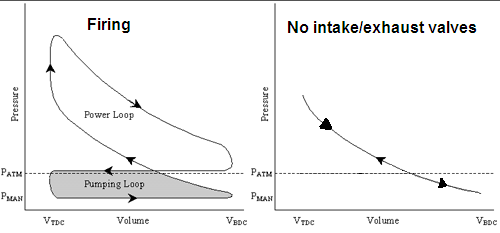

Compare that to the above p-v diagram. This represents a cylinder which has its intake and exhaust valves deactivated. The shut-off piston does no work, so it has no power loop area. Notice also that the shut-off piston needs no work, since it is not pumping anything. Therefore, its pumping loop area is also not there. The remaining cylinders still have to increase their work output to compensate for the deactivated cylinder, but now they don't have to also cover the deactivated cylinder's pumping work, because the deactivated cylinder is not pumping anything. This allows for a small, but measurable, savings in fuel.