Quote:

Originally Posted by greasemonkee

The D15B 3 stage vtec engines originally came with a one wire O2 sensor, maybe I've been missing something, but I don't see anywhere that the 3 stage was a leanburn from the factory. Nevertheless, the three valve mode has the potential to operate in leanburn to my knowledge. I almost bought this engine, but parts for an engine with Siamesed vtec spool valves?

For the skeptics claiming it will "melt" the engine to operate WOT in leanburn - Heat = pressure, thus pressure = heat. There literally is not enough of either to damage the engine. Combustion temps are cooler in leanburn producing 25 hp than at stoich fueling producing 25 hp. Flame propagation must be fast enough to minimize waste work (pressure before TDC), otherwise so much timing would be required that most of the energy released (pressure/heat) would be making the engine work against itself - the reason you can't just take any engine and expect it to run lean efficiently.

Combustion temps are known to be highest at stoichiometry and dropping off on either side of a lambda of 1. Only problem is the high oxygen content becomes dangerous at slightly-leaner-than-stoich ratios where temps are high, that is what will destroy an engine - if the heat isn't there, the oxygen is harmless.

I would be concerned about trying to squeeze off much more hp in leanburn, and I'm sure there is a point of diminishing returns somewhere along the line.

The HX engine would probably run fine on a P07 ecu, the timing tables would be out a little, but as long as the injectors were the same cc and you used the L1H1 O2 sensor it should work.

I'll look into making a fuel log, some days require a rush where I could care less about economy so to see the numbers on a graph may appear like a sawblade.

|

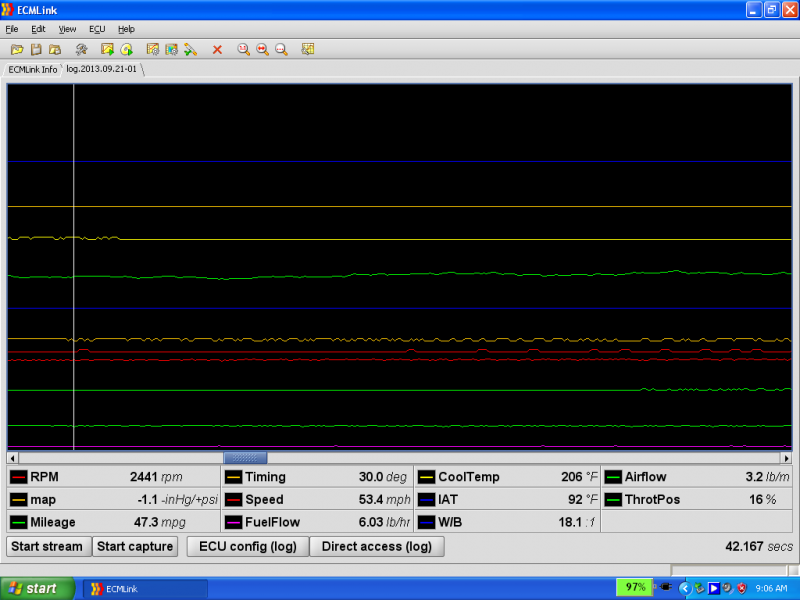

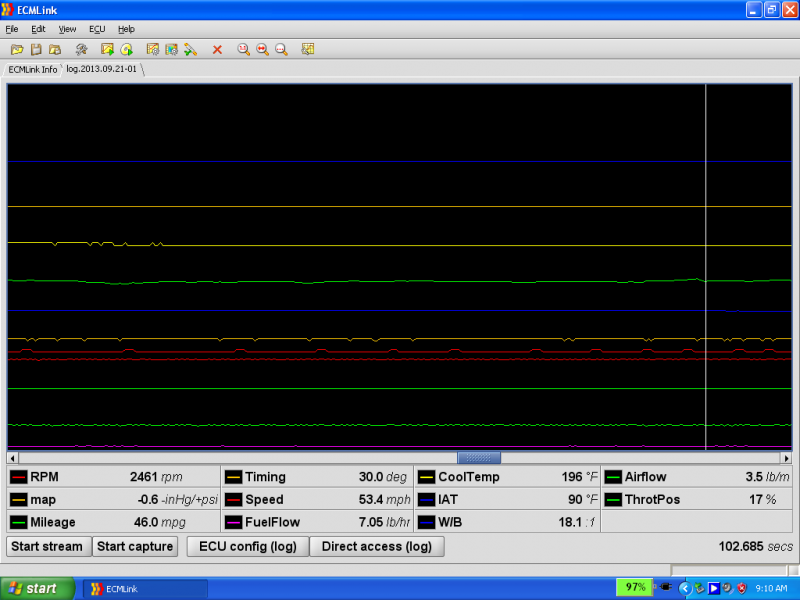

Heres some data from my Lean Burn Talon at 29:1 A/F ratio.

The first pic is the starting point where the engine just starts to go into lean burn. Notice Coolant Temp at 206*F and IAT at 92*F.

Here's the ending point of this data log. Notice the Coolant Temp at 196*F and the IAT at 90*F. From this point out the IAT will stay at 90*F until the ambient air Temp changes drastically. The Coolant Temp will actually drop another two degrees to 194*F in about two more minutes.

I have seen data logs during 95*F days in lean burn mode where the coolant will drop below 200*F and the coolant fan won't turn on anymore.

Normally my engine stock runs a coolant Temp of 210 *F.