|

Changfa diesel + Suzuki

Join Date: Jul 2012

Location: Northern, NY

Posts: 527

Centurion - '74 FIAT X1/9 Centurion Full Race DNA Last 3: 143.5 mpg (US)

Thanks: 160

Thanked 463 Times in 235 Posts

|

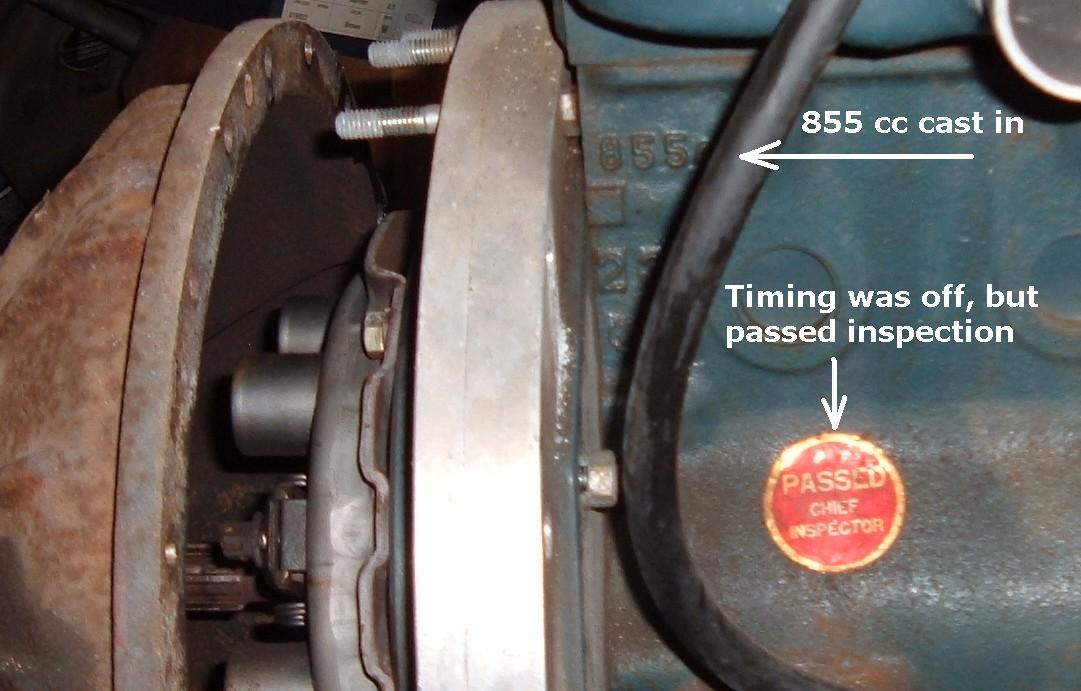

Details #6 - Centurion's Kubota D850

If there is a technical side to Centurion, this posting is probably the one area where it exists; the Kubota D850 three cylinder diesel engine.

The original plans for Centurion selected the D750 but a D850 or D950 all belong to the same family and will interchange with only minor variations in horsepower figures depending on whose graph you're looking at. When you increase the bore sizes of the D750 (762cc) cylinders just 2mm each, the displacement swells and you get a D850 (855cc). Increase the bore sizes by another 2mm and the D950 (927cc) is born. The D950 is the end of the line for punching out the cylinder bores and thus the end of the family line.

-------------------------------------------------------------------

Below is a snapshot of the Kubota D850 and three other engines:

-------------------------------------------------------------------

Kubota D850: 855cc or 52.2 cu in

Bore and stroke: 72mm x 70mm (2.83in x 2.76in)

B/S ratio = 1.025 - slightly over-square

22:1 compression ratio

VW 1.9L TDI 1896cc or 115.7 cu in

Bore and Stroke: 79.5mm x 95.5mm (3.129in x 3.759in)

B/S ratio = 0.832 - under-square

19.5: 1 compression ratio (1.9 TDI 90 and 110 BHP engines)

Cummins 5.9L (5900cc) or 359 cu in

Bore and Stroke: 102.1mm x 119.88mm (4.02in x 4.72in)

B/S ratio = = 0.851 - under-square

17:1 compression ratio

Chevrolet 4948.89cc or 302 cu in

Bore and stroke: 101.6mm x 76.2mm (4in x 3in)

B/S ratio = 1.33333333 - over-square

11:1 compression ratio

A quick glance at the Kubota D850 reveals that it has a truly high compression ratio, and is slightly over-square.

So how is this potentially useful? Well, with a high compression ratio, the more air/fuel mixture will be compressed and the more powerful combustion will be. At 22:1 compression ratio (over 400 psi) the little Kubota should have no trouble encouraging major f-bombs in its combustion chambers!

Secondly, unlike most diesels, it's not a "stroker". Having a larger bore than the length of the stroke, will by default place it in the "over-square" category. Dividing the cylinder bore by the piston stroke is the formula for this. The larger the result (like the 1.333 of the successful Chevy 302 V8) generally makes for an attractive race engine, but that's not what we are looking for, however there's a benefit here: with its relatively short stroke, there are lower friction losses due to reduced distance traveled during each 360 degree of engine rotation, as well as lower crank stress that's due to the lower peak piston speed relative to engine speed. Hmmmmmm...

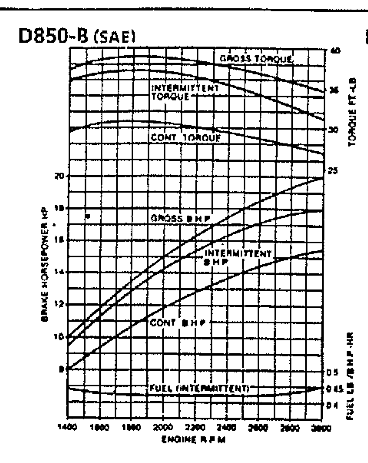

Recently, Redneck was kind enough to provide me with a very extensive Kubota pdf which has a chart that convinces me I now need some reading glasses (Not the little thin skimpy lensed ones either - thank you Redneck!).

.

.

.

For the Kubota D850, that chart outlines lowest BSFC over a fairly wide range, but from about 1800-2300 rpms is premo. This is the rpm range Centurion stayed in during the entire Stage 1 fuel economy track run – how’s that for dumb luck? And not to jump the gun but there were segments of that course where the engine fuel delivery was effectively cut off (more on that in a separate details posting.) Although I didn't have the D850 BSFC chart years ago, it does correlate nicely with the BMEP (Brake Mean Effective Pressure) at peak torque (just as the BSFC - Brake Specific Fuel Consumption does). As you'll see, using this info did help to expand on the D850's strengths.

The mathematics of this engine show that it is versatile enough to take advantage of lower friction losses at a higher rpm, and we can still take advantage of the power at the relatively flat torque curve it can make at lower rpms.

In short, this is a sturdy, versatile little engine that sips fuel, and should last a very long time with proper care - but isn't that what these little Kubotas are known for anyway?

-------------------------------

A little background info - fwiw:

-------------------------------

As a mechanic since late childhood, I have a fairly broad-base of knowledge. From personal projects, used cars, fleet mechanic, and motorpool mechanic 63T10-D1 in the Army, there's a few hours of hands-on experience here. Electrical knowledge comes from off-grid power generation (12 years now). Extensive energy management (to include practical aerodynamics) from triathlon training.

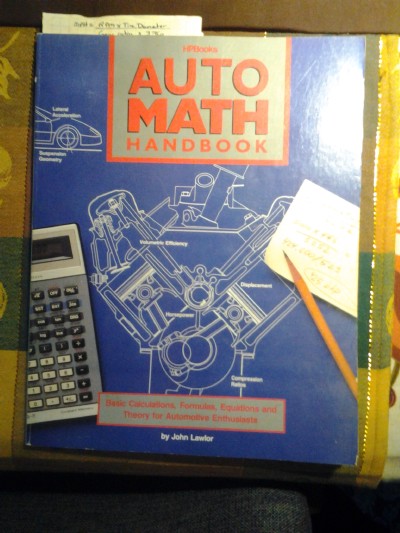

Additional background stems from a book I've owned for a very long time: HPBooks-1020: Automath Handbook by John Lawlor. (The Commodore 64 was the state-of-the-art computer to have back then!) The most recent tool in the arsenal is the online aero template I found here at ecomodder. This is one of the most useful tools I've ever found on the internet, +5 stars! aerohead used it a few posts back to give an overview of Centurion - nice work!

.

.

.

And finally, there was also an era spanning a decade or so when classic cars/trucks/motorcycles overtook my property - mostly 1955-1964 Cadillacs but there were Pontiacs, Fords, a Linclon, a few Mopars and AMCs, and a Karmann Ghia to round out the array. This entire Centurion thread is already image intensive so I'll hold back on those pics except this one: completed outside, from the ground up, including the paint job.. And what if it started out as a hardtop?

.

.

.

Some of the engines in those cars ran strong, some did not. At some point, there was a need to look deeper than just carburetors, points, ignition timing, distributor advance, fuel systems, and exhaust, etc. Heads, valves, and cylinder compression was the next step and as interesting as it all was, none was as intriguing to me as crank-cam-valve timing. One such venture was replacing the camshaft in an AMC Gremlin - mustard yellow with a Levis Denim interior from the factory - yeehaww! The only car I ever owned with an AC setting labeled "Desert Only"...

Sporting a straight six (232 cu in); that camshaft seems much longer than it is when you’re trying not to score the cam bearings during installment! (I'll bet the older straight 8's and such were a total blast!)

Surprisingly, lining up factory timing marks was not always "spot-on" with specific timing data figures. Yes, the engines would run, but technically speaking, they weren't exact and were mostly running within an "acceptable range". This should come at no surprise since manufacturers may pump out hundreds of thousands of units (sometimes using different suppliers of internal parts of the same part), so it's possible to have a sample that is "close", or within acceptable limits, even if less than optimal. I often saw and wondered how two seemingly factory identical cars (except for color) didn't perform equally. Even with the same driver; one would run the ass right off the other. The differences at the end of a quarter mile strip may have seemed trivial, but they were there. And over the lifetime of the engine, what would that be worth in say - longevity, or, miles per gallon?

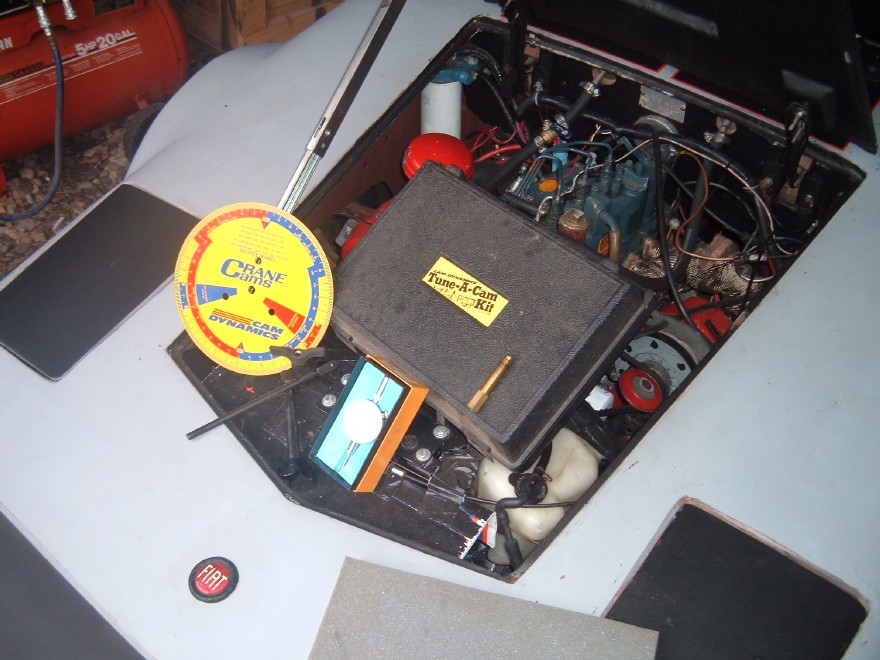

These experiences are what led the drive to "index" the Kubota that’s in Centurion. If there was a small variation in the cam timing, it may have been a huge factor in missing the mpg figures Centurion was capable of. To add an interesting twist, Kubota engines are generally recognized as being "precision", so, it was possible that the time spent to index the engine would be completely in vain. Also tilting the scale against doing this is the fact that the D850 uses helical type timing gears and not a timing belt or chain. This should result in a more consistent crankshaft/valve/timing relationship since the gears resolve the problem of a weak belt tensioner or stretched/sloppy chain.

This of course assumes the timing marks are correct; and what happens when you "assume"?

There's only one sure way to know and that's to check it!

------------------------------------------------

Indexing the engine / degreeing the camshaft:

------------------------------------------------

This job is pretty straightforward but does require attention to detail.

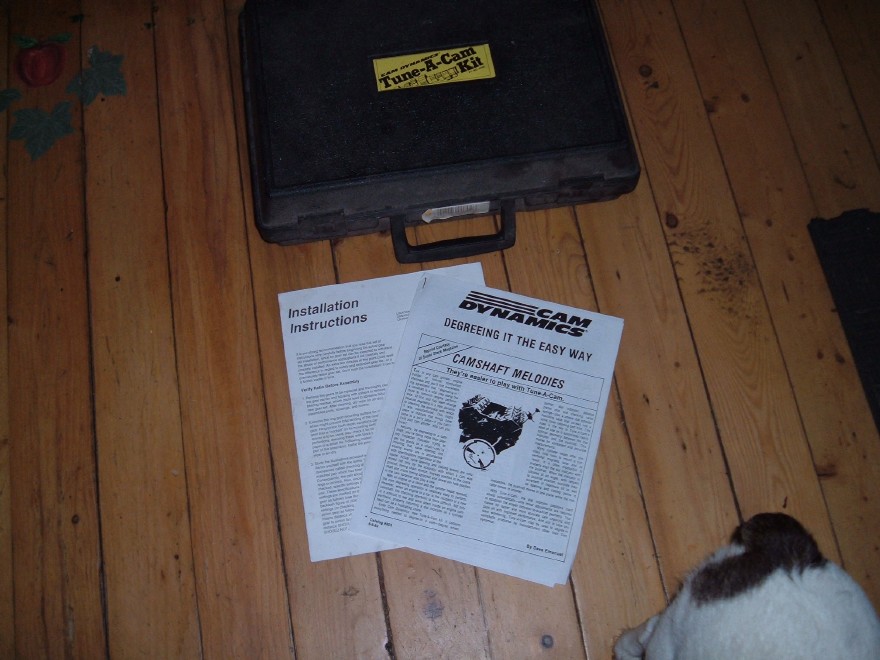

For the job, the tools must be up to the task at hand and the following items will make it easier:

1) A degree wheel and a wire pointer (or a way to accurately determine crank position).

2) A Top Dead Center stop (to find true top dead center of the cylinder you are measuring - usually #1 cylinder.)

3) An accurate dial indicator and anchor mount (to check the chosen cylinder's intake valve indeed opens to x-height at a specific degree of crankshaft rotation.)

These items can typically be found in a Cam Degree Kit (google search)....

In fact, generically, the entire step-by-step is nicely outlined on the web and there's even video on youtube. Although you may see differences in 4-cycle engines layouts, degreeing a cam is procedurally the same.

.

.

.

.

For brevity, let's cut through the chase and go for what came out of this exercise:

The valve timing was very close but not spot-on per specification.

In a sound engine where valve timing is not right on the money, the following two conditions can occur:

1) Advanced timing - where the intake and exhaust valves open early.

2) Retarded timing - where the intake and exhaust valves open late.

The implications of advanced/early or retarded/late valve timing can have a dramatic affect on the engine's output and overall driving experience.

Knowing the exact timing of the engine allows you to choose an action that works for your application - in this case the D850:

1) If it's spot-on, you can leave it alone and the engine is set for good all-around general use.

2) If it's off a bit, you can correct the timing so it is spot-on per specs and the engine is then set for good all-around general use.

3) Using spot-on as an index, you can then advance the fuel timing by a specific amount to target power at the lower rpms.

4) Using spot-on as an index, you can then retard the fuel timing by a specific amount to target power at the higher rpms. (Although I've never found this to be useful on a gas or diesel engine - throw it out there anyway.)

As some of you read the above I'll bet the gears are turning in regards to bsfc, but before you dive into anything please consider the following important points:

#1) What is the intended purpose of your project? What is the primary goal to achieve? Is it a high rpm drag strip tire burner? Or a low-rpm fuel miser? Or something else? This is important to answer because most engines' valve timing is fixed - once it's set - that's what you're stuck with. (This can also apply to the fuel timing side.) It is a compromise at best and what you gain on the low rpm side, you normally lose on the high rpm side and vice-versa, so choose wisely.

The purpose of this Centurion simply followed RQ Riley's original intent - a high mpg commuter car with the look of an expensive sports car. (My vision is all of that, complete with battle scars and patina for an embattled retro look..) Using this description and the strengths of the D850's design (as outlined above), the choice was clear: index the valve timing, then advance the fuel timing to enhance power at lower rpm and hopefully lower the point for bsfc/bmep. Is this possible? There’s academic arguments on both sides of this issue.

#2) There is a relationship between the engine’s performance and everything downstream from it. If you cannot effectively deliver your engine's capabilities to the pavement, then you've missed the mark. Those who race 1/4 mile know that "spinning ain't winning", because while you're spinning, your opponent is now winning halfway or more down to the finish line.

Competing for high-mpg isn't much different. The 4.11 Spitfire stock rear differential combined with the approx 3000 rpm limit of the Kubota diesel is not a good match-up and would only yield a lack-luster 45mph and do nothing noteworthy for super-mpg, or reasonable speeds beyond an urban neighborhood setting. To go past this required an the optional overdrive on the transmission, or a differential with a numerically lower ratio (3.27 in this case) to attain a top speed of 65 mph and perhaps more significantly, lower the rpm into the engine's bsfc at urban commuter speeds. (RQ Riley did recognize this many decades ago and hence the overdrive is noted in the plans for Centurion.)

#3) If changing/correcting valve timing, it may be necessary to tweak the fuel pump timing since it too will be affected. The D850 does not have a computer, or an engine management system "per se" as you might see in current autos, so tuck it in the back of your mind you might need to do this.

By default, Kubota engines in stock form from the factory are setup for good all-around general-purpose use. This is also the easiest configuration for the average do-it-yourselfer building a Centurion, but if needed, and the valve indexing and fuel timing advance is done correctly, this should work excellent and help to go beyond the fantastic fuel figures posted in 1982.

---------------------

Back to the problem...

---------------------

The valve timing was not spot-on and corrective action to be spot-on with #1 piston tdc (top dead center) required the cam to be advanced a tad.

.

.

.

With a true "indexed cam" the fuel pump timing could now be addressed. My notes are somewhere in the 5 degrees range for the pump once the previous was corrected. Fuel timing at the pump is just a matter of playing with the shims to advance or retard the pump timing. Valve lash adjustments were maintained per Kubota's specs (no changes there.)

The end result is a strong little engine out of the hole and right up to the 45-52 mph range finally settling in 4th gear.

This showed up marvelously at the Green Grand Prix and there was no need to downshift on any part of the course - all the while staying around 1800-2150 rpms (+ or -). At this rpm range, we weren’t even close to pushing the rated 17hp@2600rpm and certainly had a little more oomph even during the uphill. The Green Grand Prix is perfectly suited for something such as Centurion. The "boot" of the track, which was omitted (hence the "short track" of the GGP), likely would've changed the outcome for everyone due to its formidable elevation change at that point, but Centurion was ready for that too. If the load causes the rpms to drop, this engine impressively just hammers away at about 1850-2000rpm. The keyword is “hammers” and that is where the earplugs came in handy during the uphill after turn 1 at the GGP.

.

.

.

If I had to design a competition exclusively to favor Centurion's strengths, it would be very much like the Green Grand Prix course and now you know why. After addressing the cam and fuel timing issues, combined with a 32 year old proven design, all while returning impressive numbers in regular driving - there was every reason to go to this event!

Indexing (or degreeing a cam) is not for everyone and may not be necessary on every engine, but when a properly setup engine is coupled with a complimentary driveline, it can yield some impressive results by any metric. It's also possible that a different bone stock D850 would perform admirably with no adjustments needed, but I wasn't lucky enough to have that one. I believe some of the newer technology helps to smooth over any inconsistencies, and with some of the tight internal tolerances in new engines there is probably less room for error, so maybe this is why degreeing a cam is no longer as common, making it a thing of the past and a complete waste of time.

-----------------------------

Closing advice on this topic:

-----------------------------

For anyone building a Centurion or using a small old school Kubota in their build, complete the project and see if it falls within the numbers of where it should be.

If it does and that's acceptable, have a good day and be on your way.

If the numbers don't fit, and, after trying everything else you're at your wits end, consider checking that cam timing and/or fuel timing. I’d love to hear what you discovered!

The next (and likely last) installment of this series will include a very unique modification tailored exclusively for the Green Grand Prix....

I'm already laughing just thinking about it...

~CrazyJerry

Last edited by changzuki; 08-04-2018 at 12:12 AM..

Reason: One technical typo...

|