12-20-2014, 11:38 PM

12-20-2014, 11:38 PM

|

#325 (permalink)

|

|

Changfa diesel + Suzuki

Join Date: Jul 2012

Location: Northern, NY

Posts: 527

Centurion - '74 FIAT X1/9 Centurion Full Race DNA Last 3: 143.5 mpg (US)

Thanks: 160

Thanked 463 Times in 235 Posts

|

- A meeting with the Governor....

.

At this point, ALL of the immediate issues are traced to the new Injection pump and Injectors but the remedy just may be through the Governor itself. Since the governor is separate from the fuel pump, then one might think it could be dealt with easily and directly - not exactly.

.

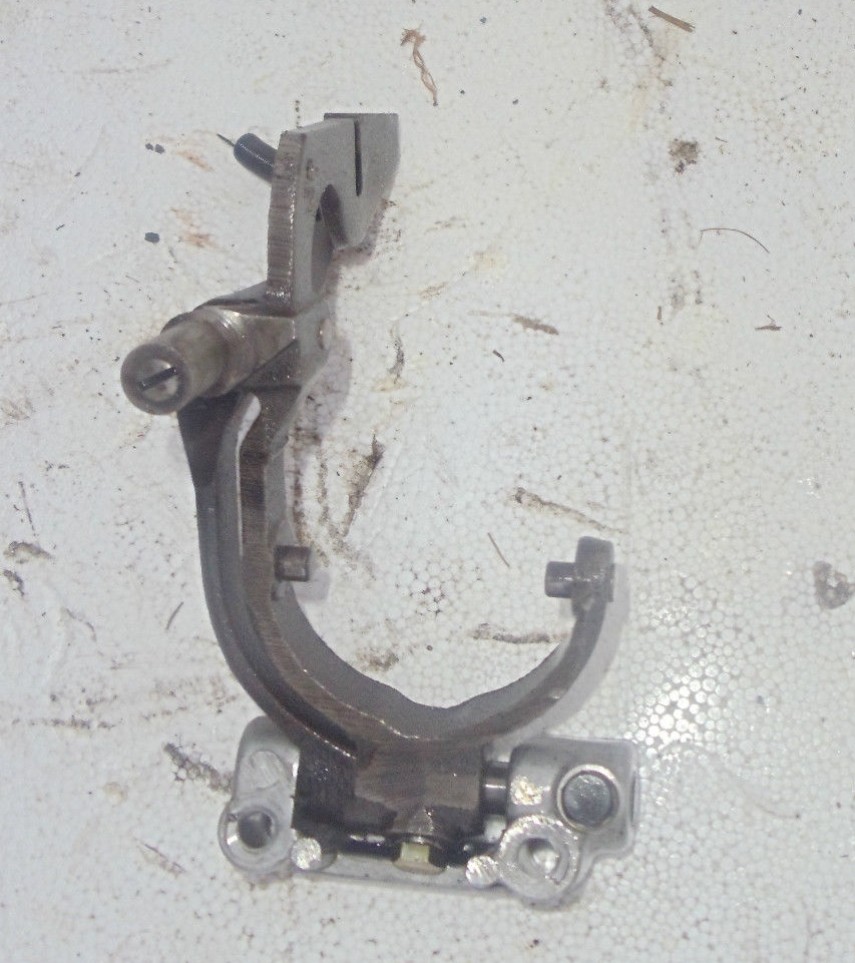

Removal of the Governor is a major job and is likely unnecessary as long as we use caution and a steady hand. To understand what's going on in relation to the problems, let's look at the governor as it would look outside of the engine:

.

.

.

.

.

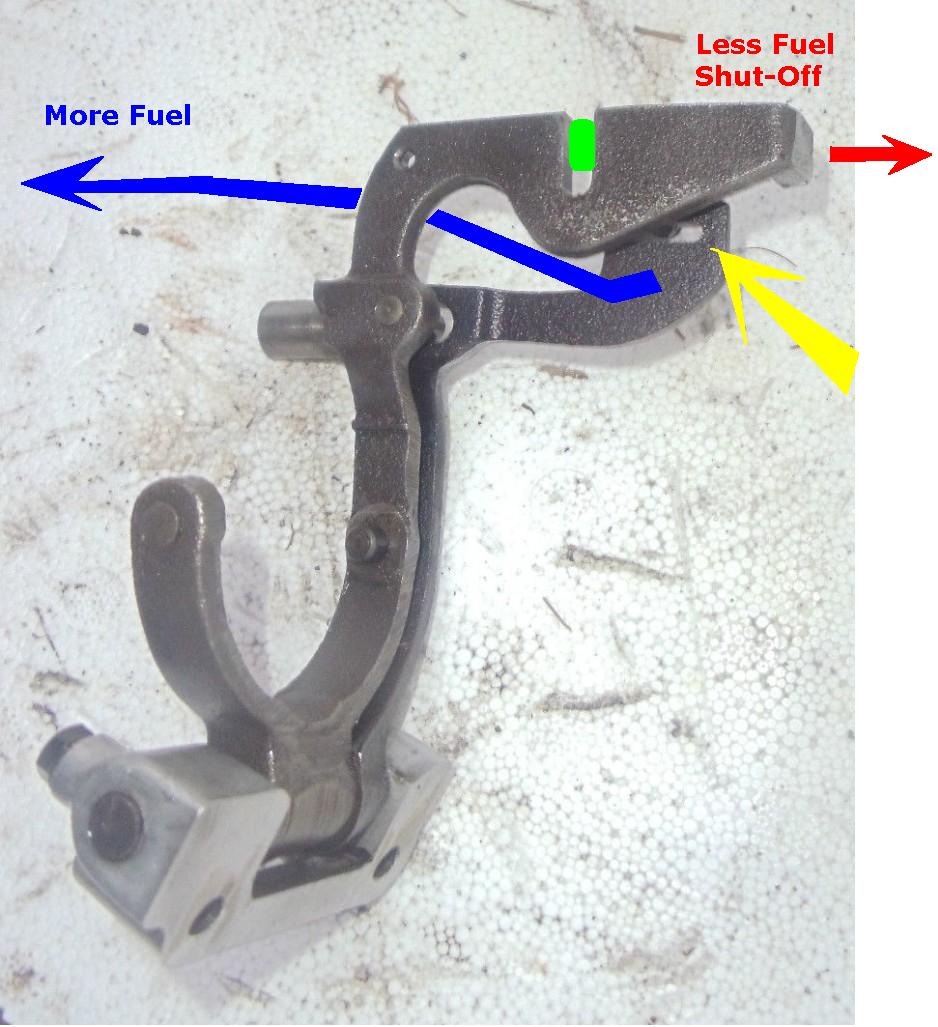

It may look simplistic but there's a lot going on when this piece is doing its job. Using the following pic as a reference, let's look at what it does:

.

.

Look at the lime green circle. This is where the Injector Pump's rack dowel pin slides down into. Once you know that, it becomes a bit more clear that as the "arm" holding the green dowel pin moves forward, the fuel rack will increase the pump's output and the engine will rev. If the arm moves rearward, the fuel rack will cut back the fuel delivered to the injectors and the engine will slow down (or stop if it goes rearward far enough).

.

When you push down on Centurion's accelerator pedal, you are really only pulling on that arm via a spring. As the engine begins to rev near its 3000 rpm limit, the centrifugal force of the fuel pump's camshaft weights act on the same arm to push it rearward, thus limiting the fuel rack's travel - this way you don't over-rev the engine and blow it to smithereens.

.

Notice the yellow arrow in the above pic and see that it's pointing to a slot. That slot is essentially a "tolerance" area between the two arms. If the pulling of the accelerator spring closely matches the pushing force of the fuel pump camshaft weights, then the dowel pin from the closer arm is allowed to "free float" just a little bit (both forward and rearward) in that slot. In certain cases, likely due to both heat and vibration, the accelerator spring can resonate and then you get a bouncing back and forth action between "its pull", and the "camshaft weight's push". When this happens (in this case under a light load in any gear) the fuel rack will move fore-and-aft just enough to give you a rodeo ride (bucking action.) This normally would never happen if this engine was in the stock equipment is was designed for since there would normally be a constant load on it (Ex: A Genset, Tractor, Bobcat, etc..)

.

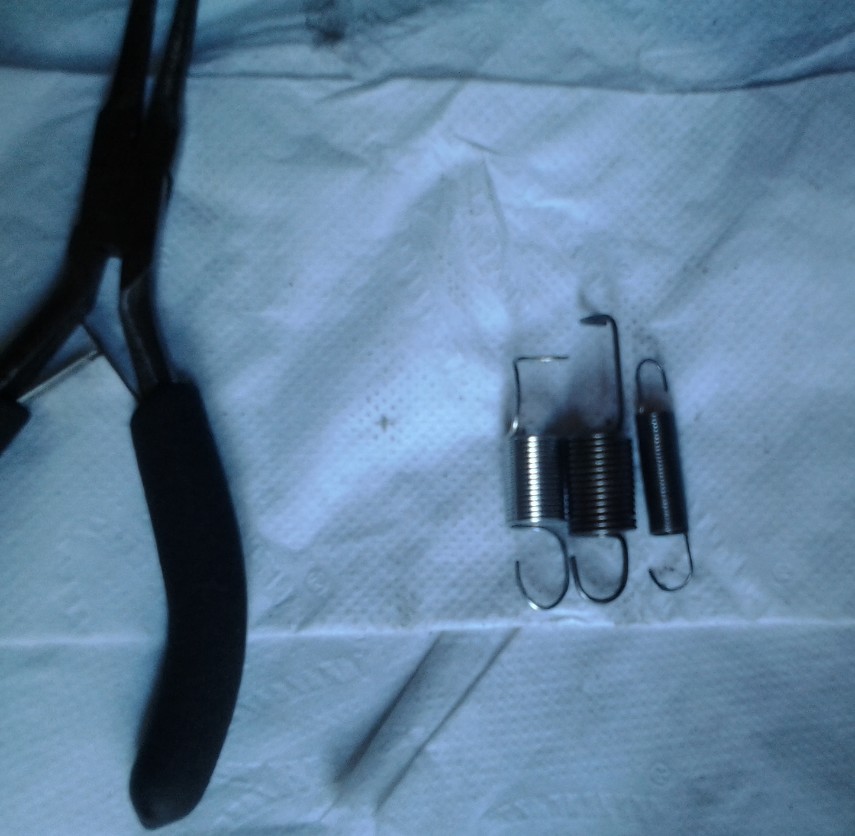

This is actually a pain in the a$$ to fix and did involve a ton of hours to the extent of making new governor springs and relocating them outside of the engine (they are mounted internally from the factory). There is very little room to work with if keeping the springs mounted internally. The pic below shows one of those springs dangling out from the engine, actually from one of the governor arms:

.

.

Here is my attempt and creating larger and smaller diameter springs to straighten this issue out:

.

.

.

After fiddle-phooking around with this forever, it finally worked really good - very acceptable and very responsive with only the slightest hint of the bucking and only if you're intentionally trying to feel it!

.

There was still the lagging issue of 2400 max rpms to deal with but clearly I was in the right place!!!!

.

.

~CrazyJerry

.

Last edited by changzuki; 08-03-2018 at 11:51 PM..

|

|

|

|