Quote:

Originally Posted by darcane

Aerohead,

I believe we are in violent agreement here, once you realize what I am actually saying and not what you think I am saying. Keep in mind that the pressure in the exhaust system varies along it's entire length and varies with time. My assertion is that it is never desired to increase back pressure at the exhaust valve at the time it opens.

What you have just described is a negative pressure wave traveling back towards the valve, timed so that pressure is reduced just at the moment the valve opens to assist scavenging the cylinder.

You have just reduced the back pressure.

It is NEVER desired to increase back pressure at the exhaust valve while it is open.

Just because it is done intentionally, doesn't mean it is desired. It is also undersized due to geometric considerations: there is only so much space in the cylinder to put all the valves and leave them reasonable un-shrouded.

And I have never suggested arbitrarily modifying the exhaust.

For an exhaust system tuned to maximize torque at a high RPM, a restriction placed late in the exhaust system may be beneficial to low RPM performance. This is not because backpressure is increased, but because the restriction alters the timing of the negative pressure waves to reduce backpressure at the valve and aid scavenging.

As I've said on the other thread related to this, a better solution for a dedicated economy car is to tune the exhaust for optimal performance at the lower RPMs where it will get the best fuel economy.

I believe the extraordinary claim is that you can improve performance by increasing the back pressure at the valve. I don't believe that this is what you are trying to say though.

|

*Okay,so now you've thrown in a caveat which was missing from your original statement which changes everything.

*Yes,at the time of valve overlap we always want a rarifaction pulse striking the exhaust valve,never a compression pulse.Bear in mind that these are sonic,sinusoidal pulses within the gas itself,then after blowdown,the piston must evacuate the remainder of the spent charge,more of just a simple subsonic pumping action.This is where the rarifaction pulse is handy,just before the exhaust valve closes,rather than a compression pulse which would cause reversion.

*With respect to the exhaust valve size,the literature underplays the significance of exhaust system friction,while overplaying intake friction as a rational for larger intake valves rather than exhaust.

*The indicated hp of an engine is limited by the unit air charge.

*The manufacturer will try to maximize the intake valves.

*They'd put larger exhaust valves in if they could,but at up to 3,000-degrees F,a large tulip cannot transfer heat fast enough to the seat and stem and we end up with a warped or burned valve.

*Some pent-roof combustion chambers will run 3-intake and 2-exhaust valves to try and maximize flow.

*With respect to timing of the pulses,whether rarification or compression is present,it is a function of reflection.

*Any structure present within the exhaust tract can cause a reflection and wave inversion.

*A valve can cause the beneficial reflection when tuned,as Yamaha did with their EXUP technology.

*Pressure,measured before the valve restriction (back pressure) would increase.

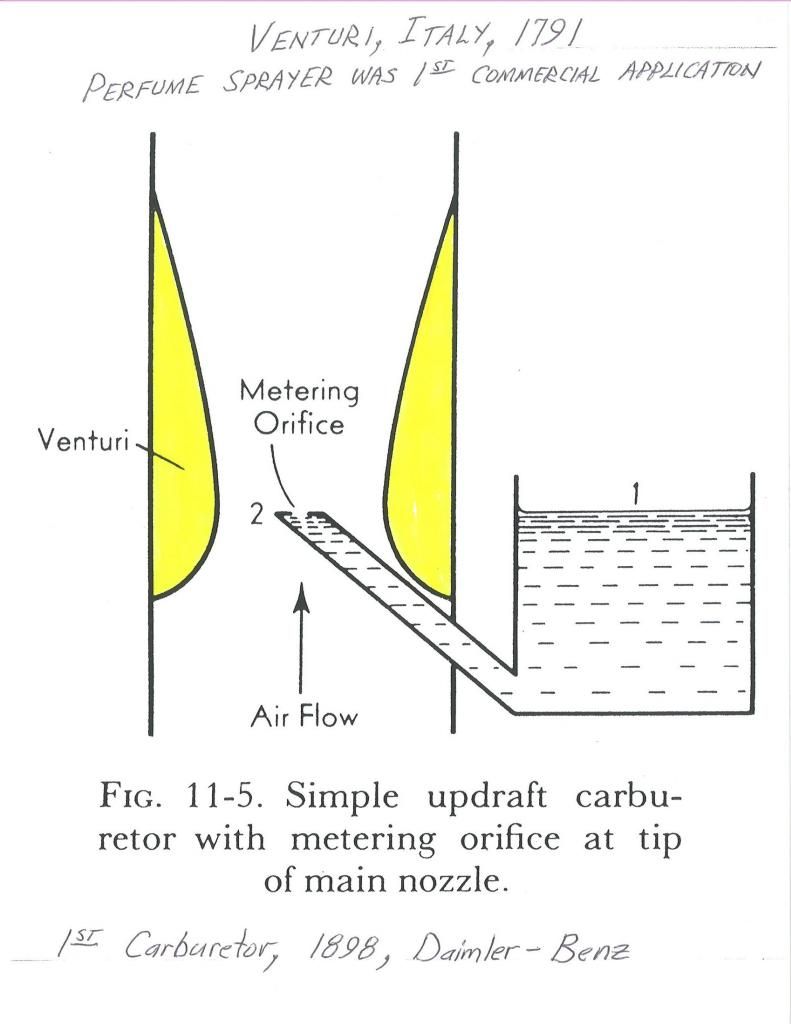

*Pressure measured within the restricted cross-section would be less (a crude venturi).

*pressure would increase again once the gases passed the valve.

*So we need to qualify where our pressure taps are located.

*In the common vernacular,the valve would be interpreted as a restriction and any gases upstream of it would encounter 'back pressure.'

-----------------------------------------------------------------------

*As Richard Waitas reminds us,all passive exhaust systems are an exercise in "concessions"."You cannot calibrate an exhaust to provide low end torque plus high end horsepower."

*Ideally,we'd travel to where Avatar was filmed and get us some 'unobtainium' for which to construct a shape-shifting,biomimetric,fully-morphing system which could expand and contract as CFM varied.

*So far,Yamaha's and today's Walker' Dynomax Valve Technology (VT) exhaust systems are as close as we've come.

*(wait 'til exhaust tuners get a load of a Pelton-wheel turbine or Junkers JUMO 004 turbojet bullet-jet valve)

--------------------------------------------------------------------------

*I'm with you on the low-speed torque/mpg wavelength.

*With respect to the extraordinary claim about the EXUP valve technology,we may be in a semantics conundrum.Most guys on the street will consider the pressure between the exhaust port and the restriction during post-blowdown pumping, and interpret the pre-restriction reading as increased back pressure.They won't think in terms of the very low pressure at the choke point.They get it with carburetors

,but not exhaust.

*If they're savvy at all,they'll understand 'tuning' and won't just randomly toss the 1st aftermarket system to come along on their car and expect results.

*It does look like 'active' systems are the way of the future.