Quote:

Originally Posted by bluebunny

Ok  Finally down to the nitty-gritty...

1. We're talking automotive/truck aerodynamics...

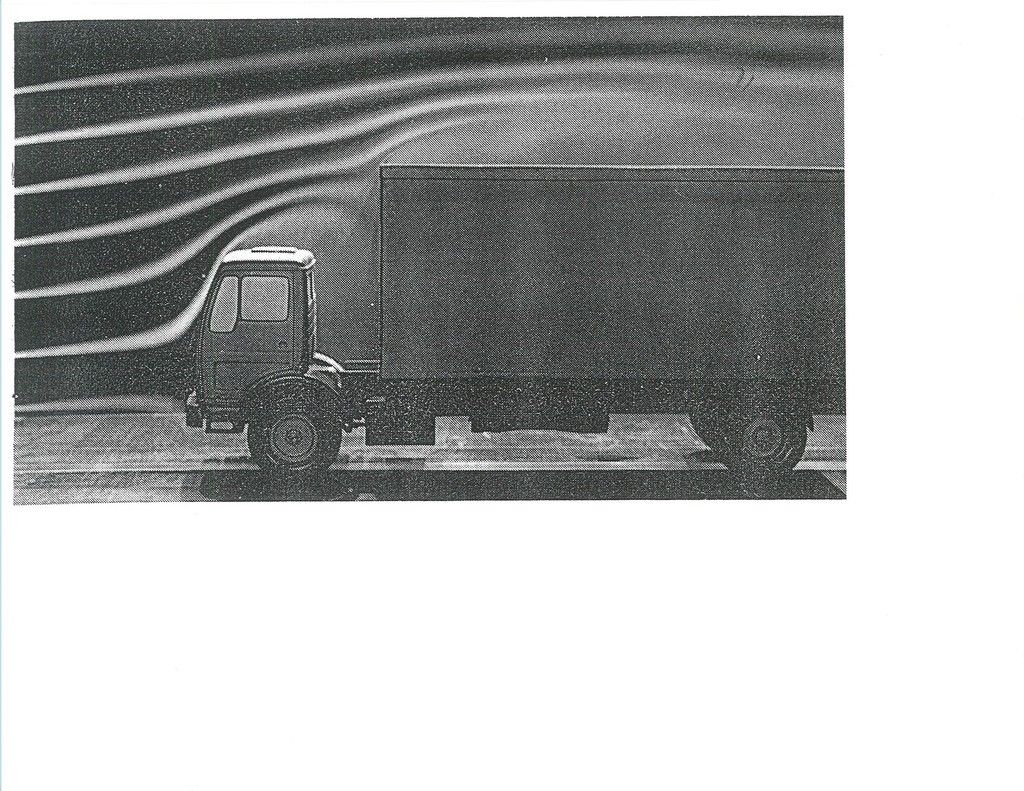

2. Say a flat-front box shape exposed to an air stream, like on high wide box on local delivery truck..

3. Modest leading edge radii on top and sides, say 4"R

4. Lets also say smooth surfaces and transitions to planes of box.

5. No cab-roof mounted air deflector.

Case 1: the 4"R leading edge radii mentioned above.

Case 2: 8" half-pipes mitered/mounted to sharp-edged box's leading edges.

Separation typically does not occur? Even in crosswinds? Even without crosswinds? |

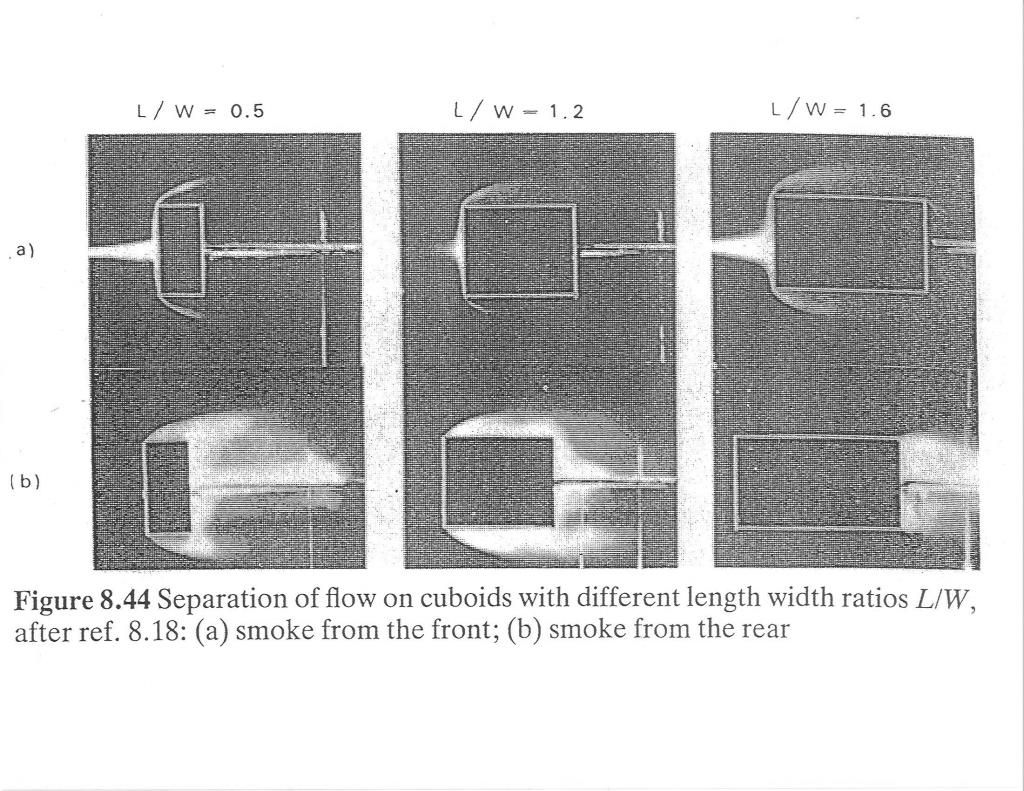

In a calm condition,with the sharp edges we'd be looking at

In a crosswind we'd have this jet blowing through the gap,destroying the flow.

In the calm condition,if the box was at least 1.6X the box width,there'd be reattachment with zero mods,but we'd have to pay continuously for the vorticity.

With no crosswind,a leading edge radius equal to around 4-5% of the box width would be adequate to kill the separation

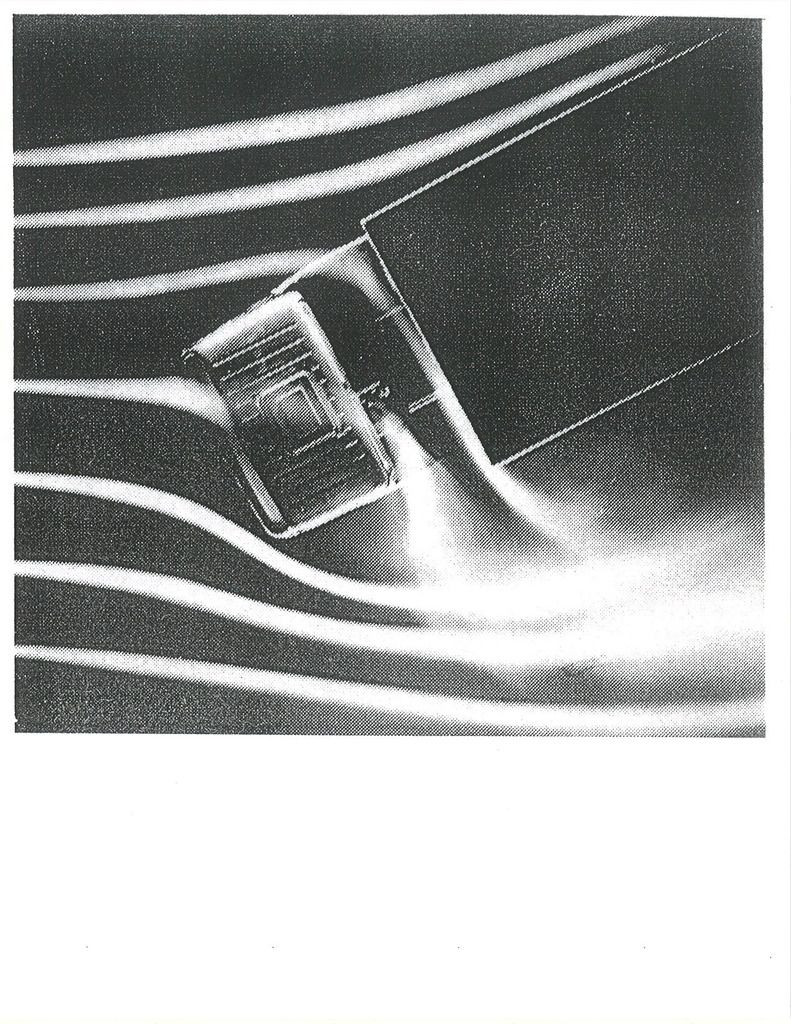

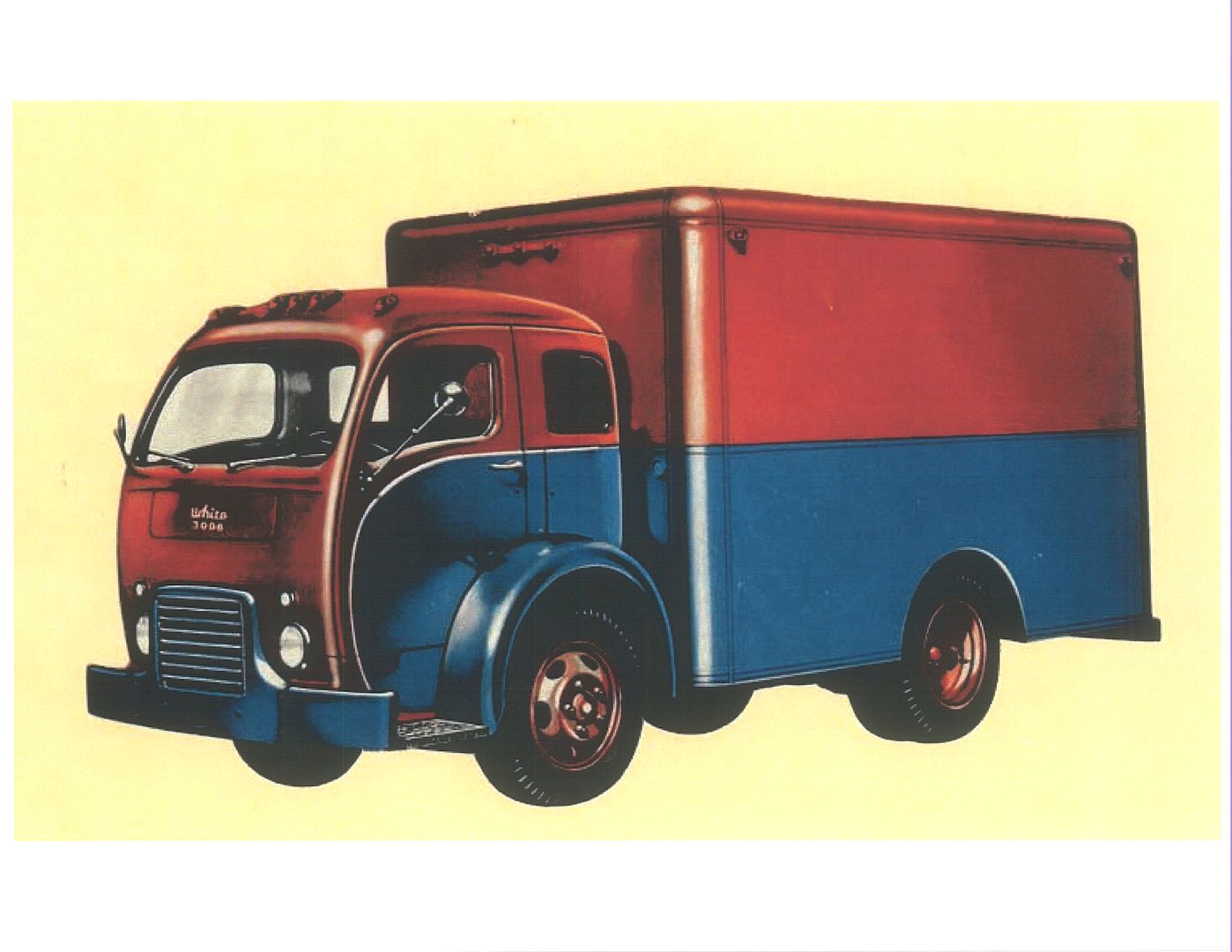

With crosswind,it's been determined with wind tunnel testing,that a 'bulbous',or 'oval' leading surface has the lowest drag for anything below 250-mph

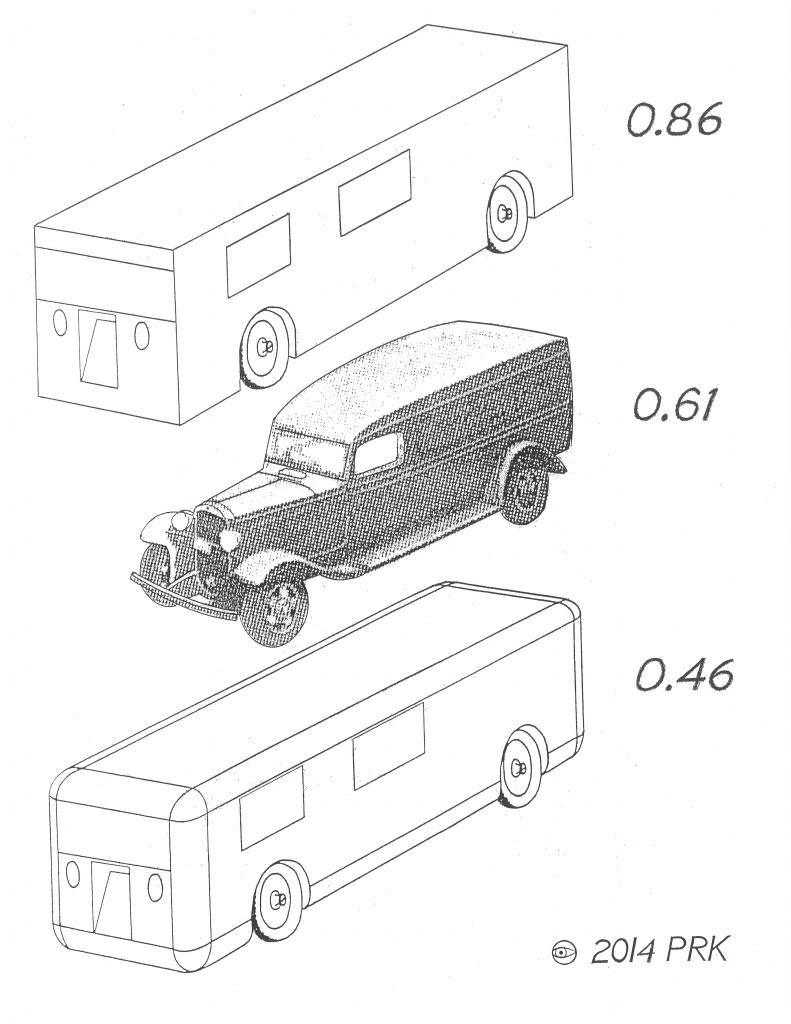

Here you can see what softening the front of a van did for the drag

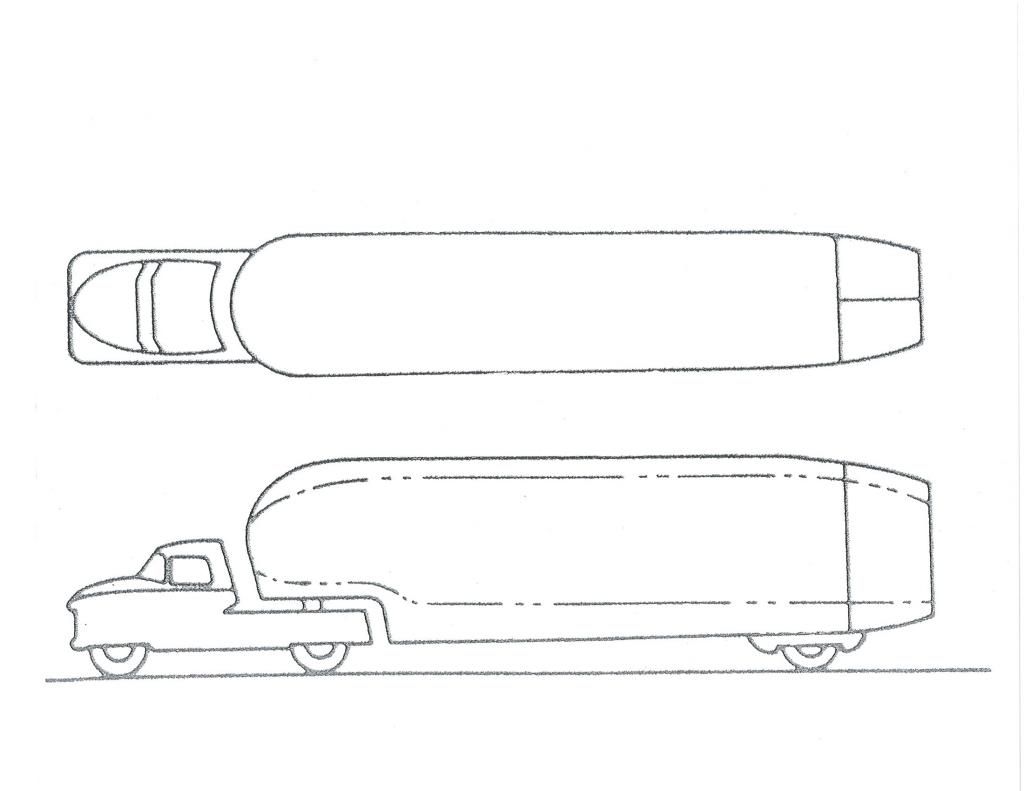

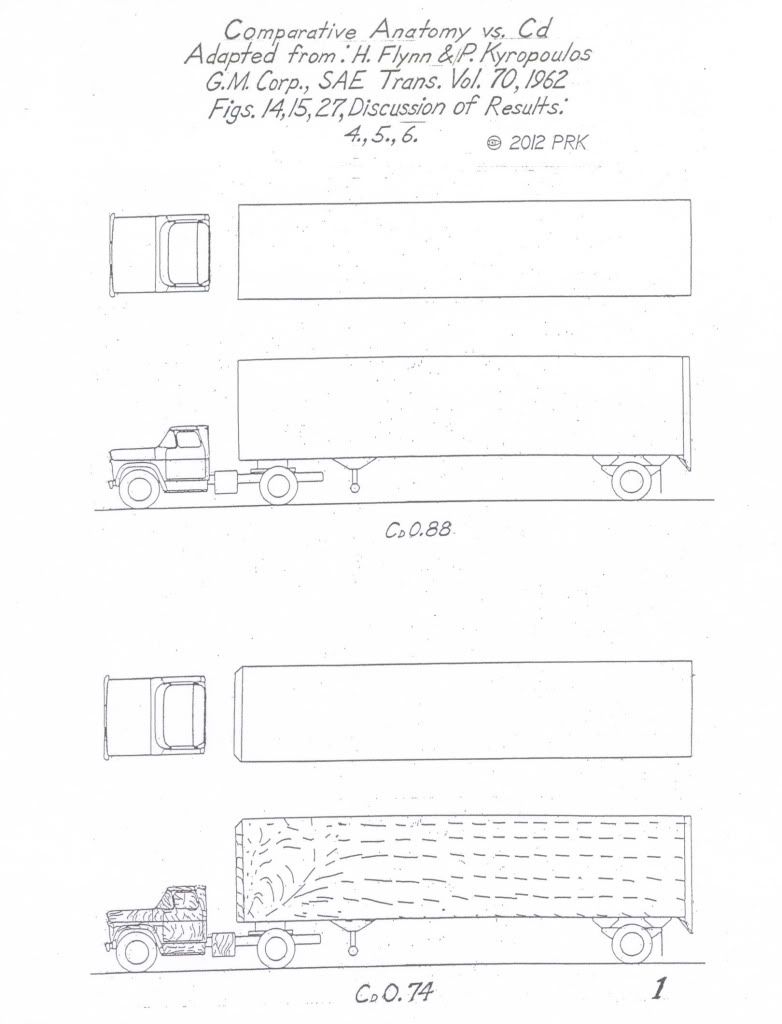

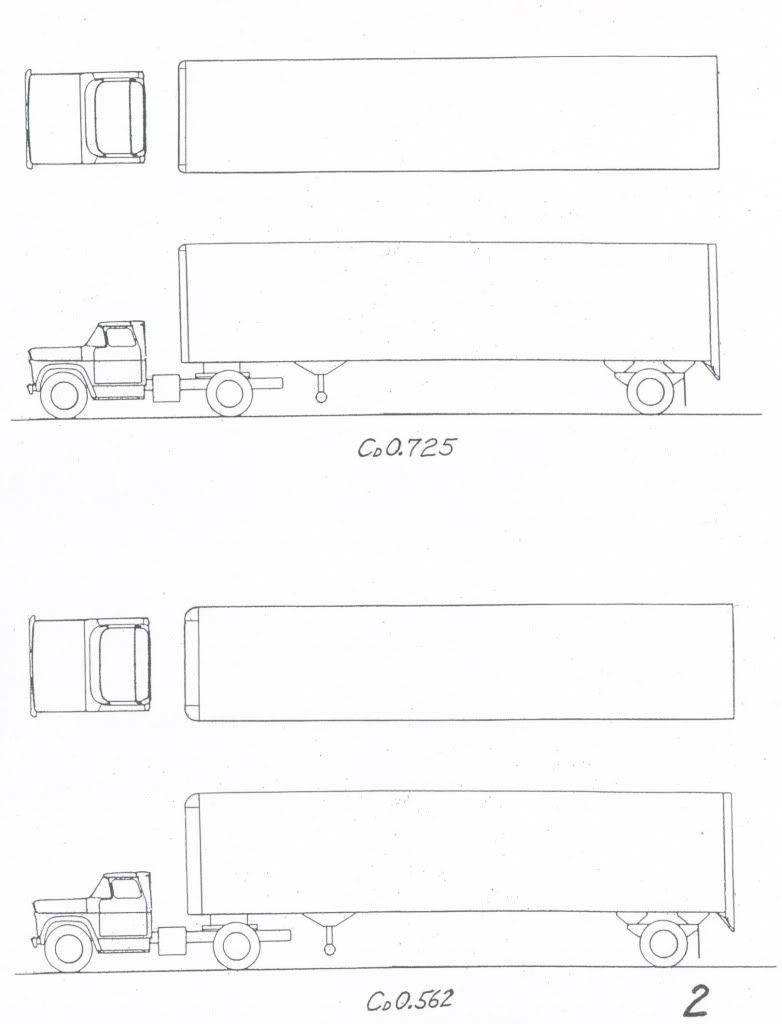

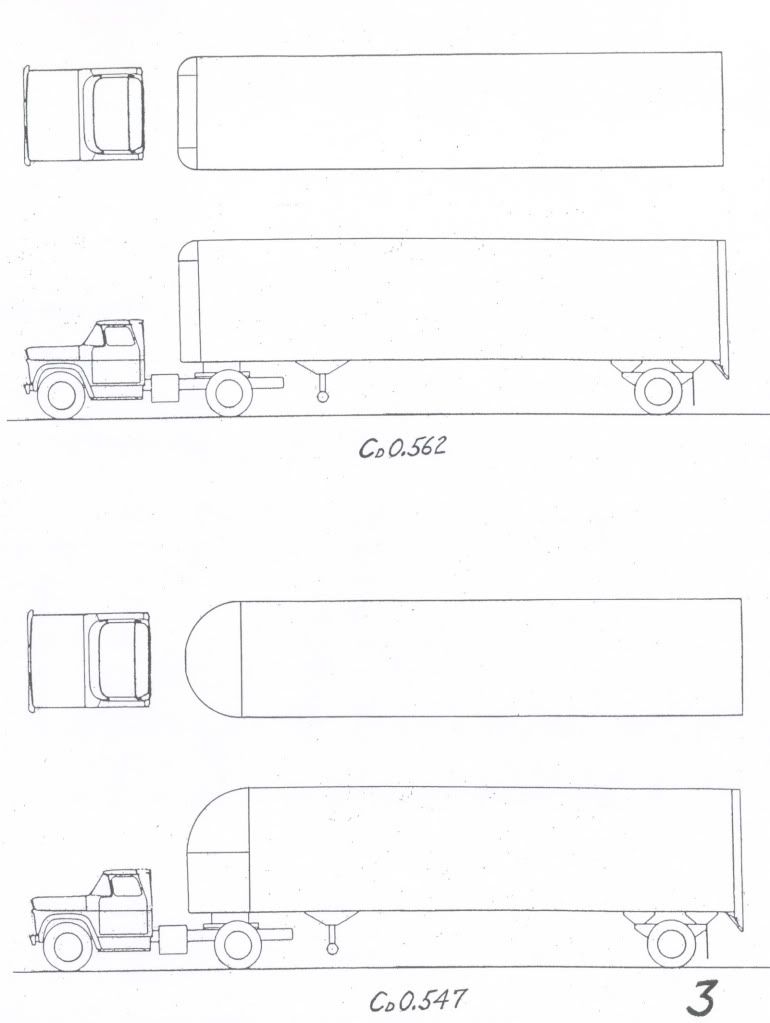

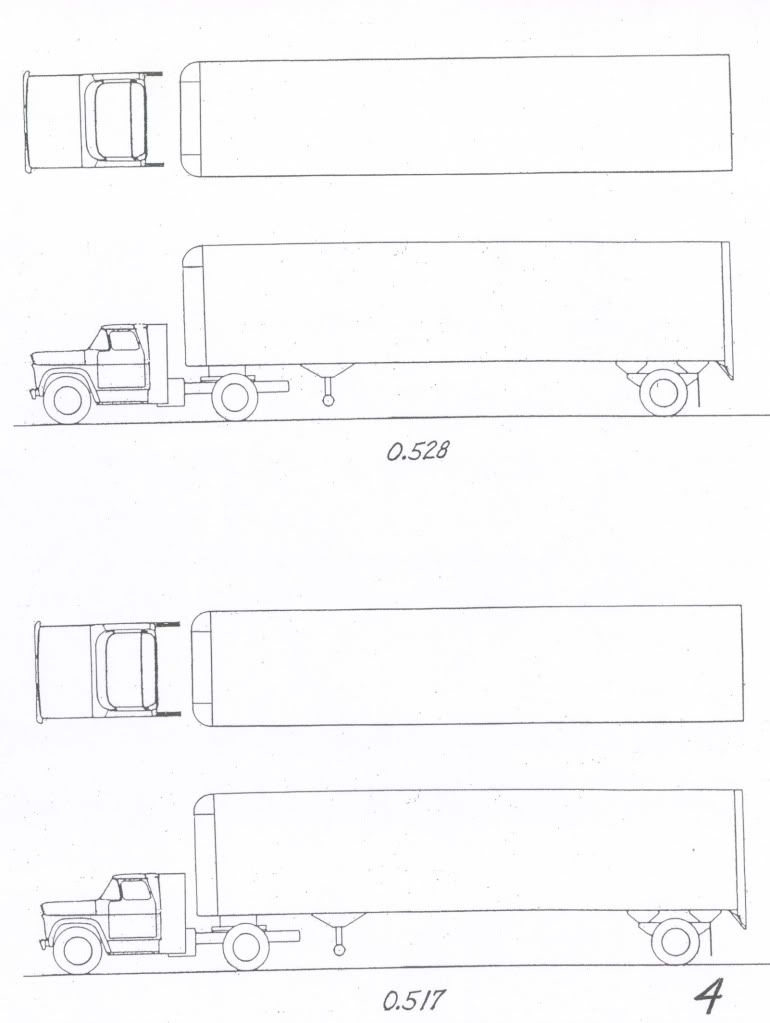

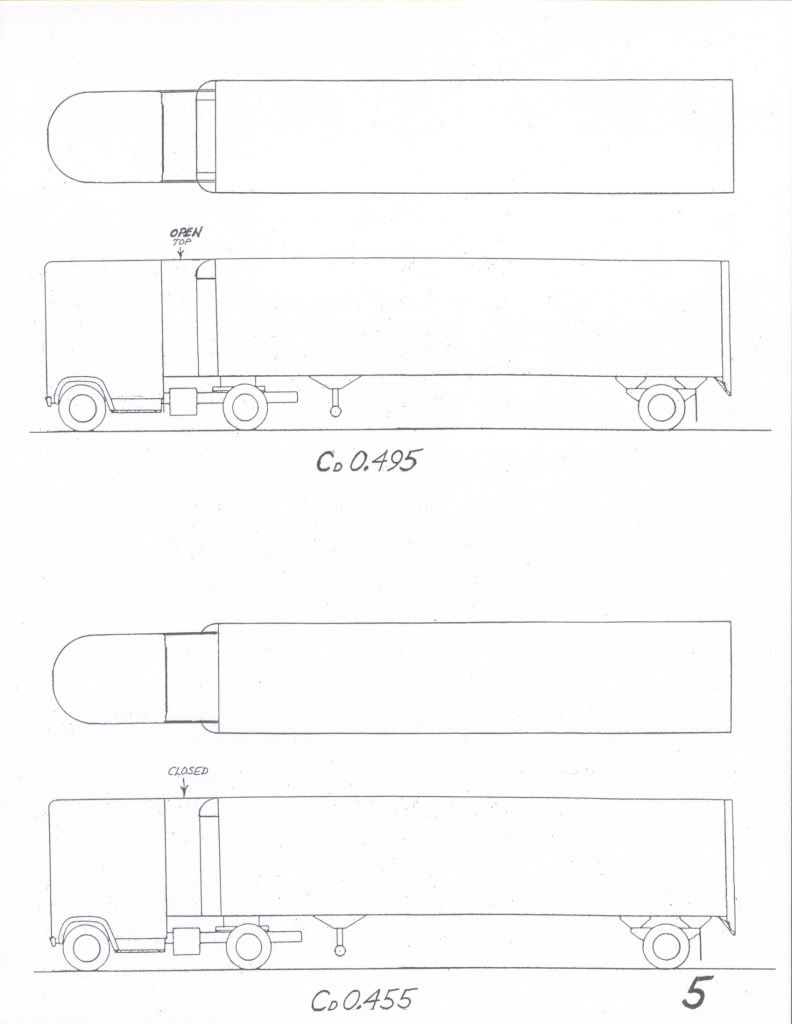

Here is a progression of drag as a function of leading edge softening and gap control which General Motors evaluated in 1963 at Cal Tech

The bulbous nose is the most complicated and expensive to produce,but aerodynamically,it has no peers.

Lower right