Quote:

Originally Posted by Pooft Lee

After finding this and reading through, I wish he had stuck around. Formula SAE experience is better than what I have access to. But the follow up data didn't really happen, which is disappointing.

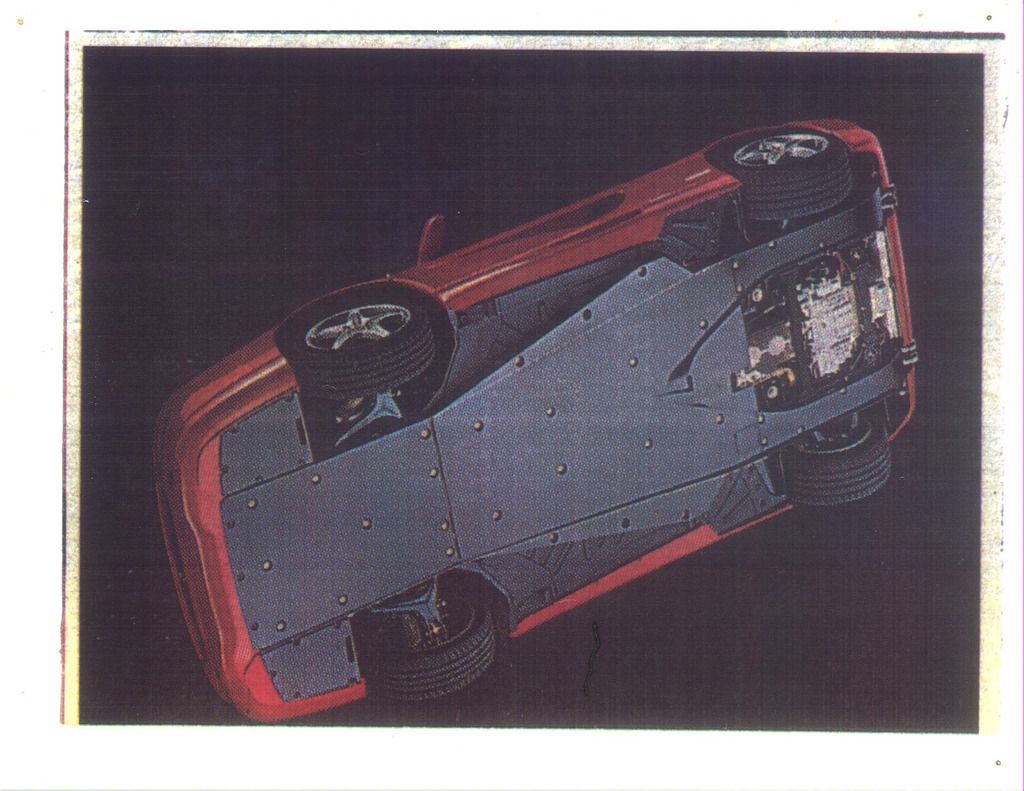

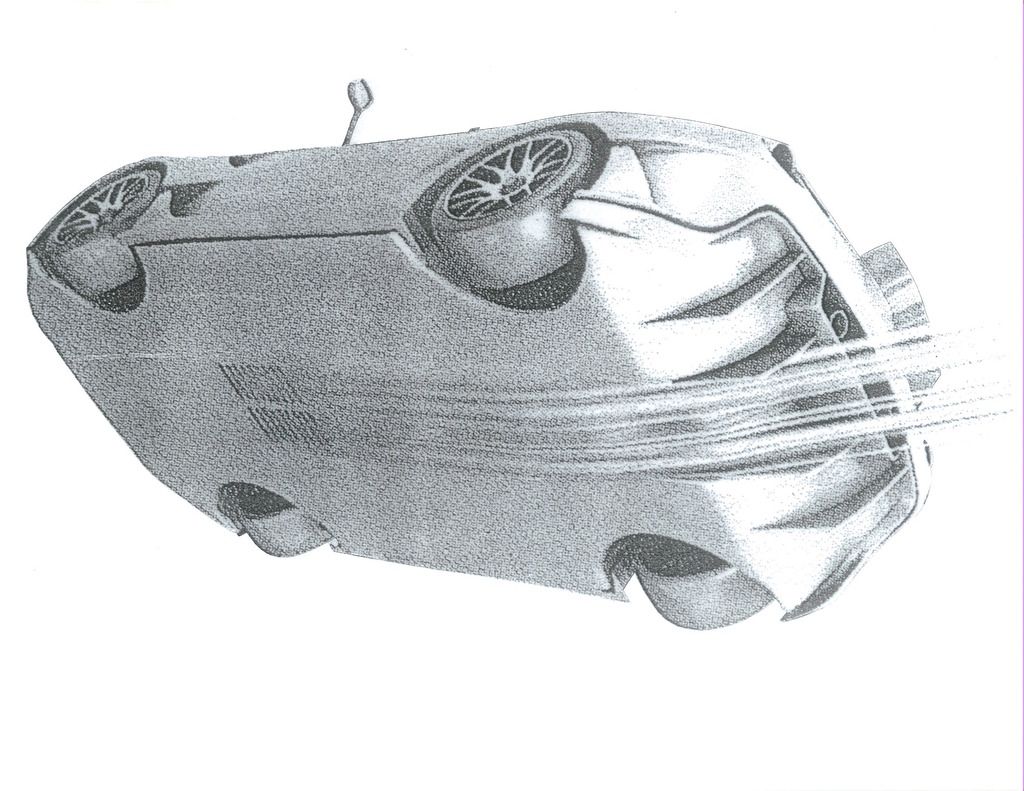

Back to the notorious audi photo, Mercedes is doing much of the same, so I think they're on to something.

While it doesn't look useful in the center, and may just be hiding attachment points, there's a clear pattern at the skirts, and they cared enough to extend the dimple from the pan to the side skirt. It looks like they're trying to generate vortices that fence underbody and outside airflow. A pretty cool alternative to low ground clearance. I've looked for CFD or other photos to confirm, but it would seem Mercedes likes to hang on to what they learn in their multi-million dollar testing facilities. Go figure. Thoughts?

|

*Due to the length of commercially-produced passengers cars,they are guaranteed a supercritical Reynolds number.They don't need artificial roughness introduced.

*This allows for full flow attachment.

If you're seeing 'dimples',you may just be seeing recessed attachment points for servicing

There's no good reason to have any

*Any dimple would actually degrade performance of a smooth panel (Hoerner is a good source for this info).

*Adding any type of VG would betray a poor design to begin with.

*And a dimple is never chosen,other than in golf balls,as a VG.There are at least a half-dozen VG designs which would out perform the dimple.

*A specific vehicle,of which it's styling and major tooling had been locked in,if found to have trouble when assembled,could be 'tuned' in a wind tunnel,and a low cost gimmick could be added to mitigate design flaws discovered.But they would just be a Bandaid.