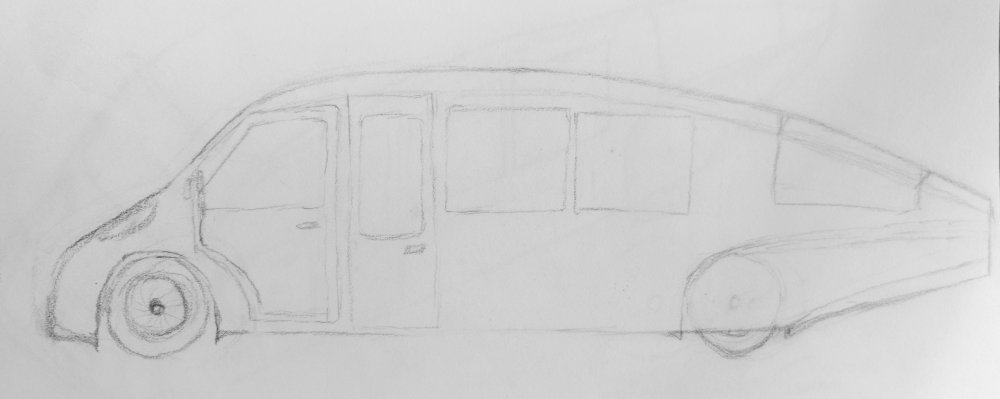

To provide a bit of an update, I ended up working on the motorhome option, as I think that suits our intended use better, and I want offroad capability (to get to many parts of Australia we haven't seen). Whilst starting from a donor vehicle would be preferable (and considerably easier), there is very little (nothing!) in the way of aerodynamic 4x4 motorhomes (or even suitable base 4x4 vehicles) in Australia. The 4x4 mercedes sprinter van is probably the closest. So I did a fair bit of looking at various concepts, and developed a preferred one.

But first, to skip to the conclusion, I've put this project on hold for 3-5 years. Decided that now isn't the right time to be putting a huge amount of effort and money into building a custom vehicle. Hopefully in several years time I'll be able to take this up again, though I think registration/roadworthy requirements (red tape) are only going to get more difficult as time goes on.

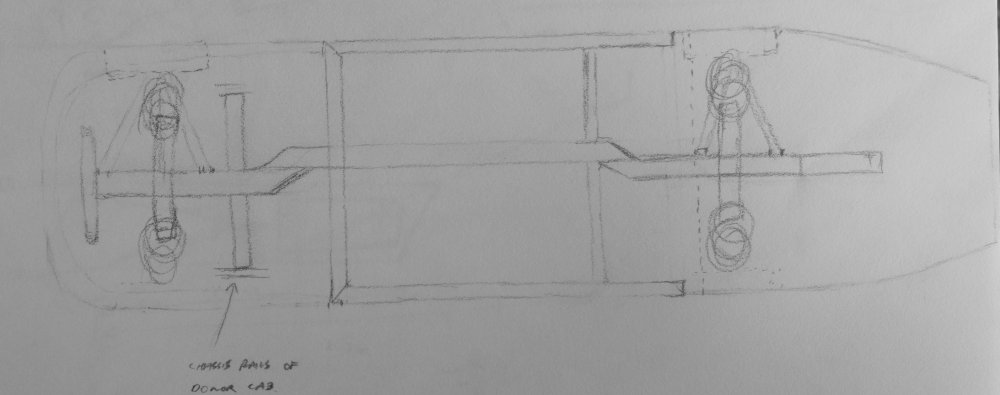

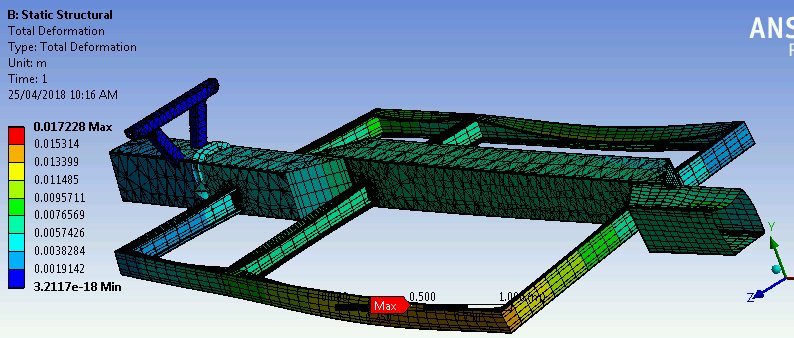

I designed a rigid centre tube (RHS) chassis to act as a structural backbone for the whole vehicle. Similar concept to

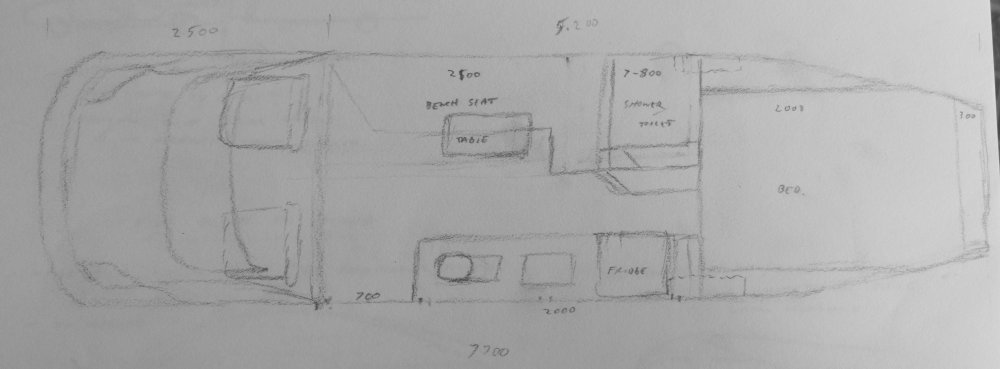

Tatra trucks. Not fully detailed, but it checks out well in FEA analysis. Custom independent air bag suspension on all 4 corners. Approx 450mm of wheel travel (max for CV joints), and airbags make it height adjustable to optimise for road (low and aerodynamic) or offroad (lifted for clearance) driving.

Two electric motors, one for front, one for rear. Motors, gearboxes and diffs (two 'rear' diffs) are actually contained within the large RHS frame (flanged top surface). Gearbox are a small custom design, just to get low range for offroad use (ie. 2 speed, no clutch). A number of different motor options; Parker make some nice ones for example. Because of the offset middle part of the chassis, can get some cooling air flowing through the RHS pieces containing the motors and diffs.

Another main reason for the offset RHS tube in the middle is to limit vehicle height - the floor for the kitchen/walkway will be beside and lower than the top of the RHS chassis. With the floor of the standing part of the motorhome also forming the underside of the body, overall vehicle height can be kept at around 2.1m with standing room inside (when air bags fully lowered). Planned an almost flat underbody, just the centre RHS tube (but not cross beams) sticking down 50-100mm or so, and there will need to be cut-outs/slots for suspension arms to move up and down past floor pan. That centre part of the chassis will also act as a water tank.

Considered a monocoque frame, and yes it could probably be done a little lighter that way, but construction would be significantly more complicated and involved (especially considering I have very little practical experience in composites, and it would be critical to get that right). Also the state of the structure would be more difficult to assess, monitor and repair (remembering this is an offroad vehicle).

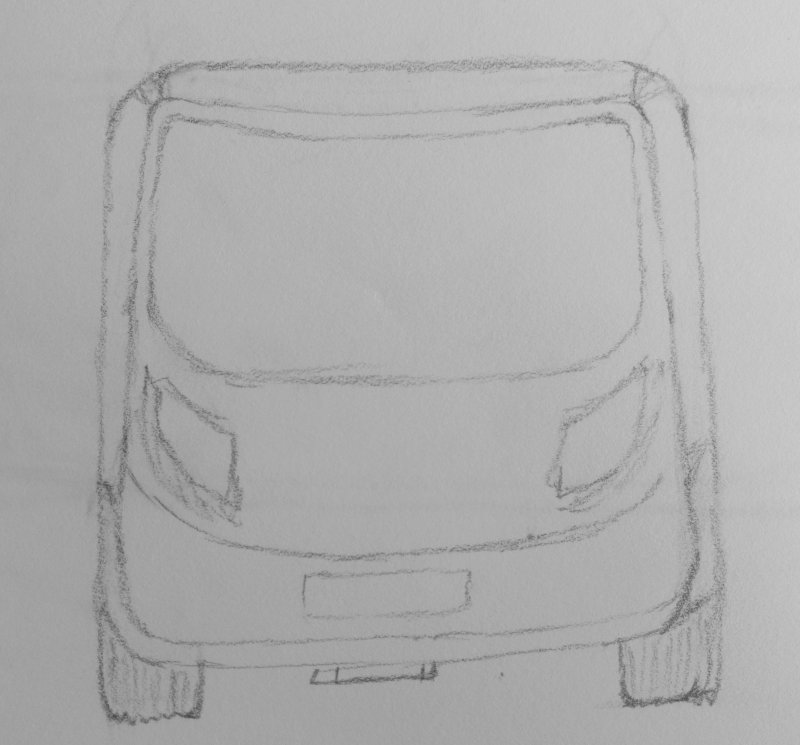

For the cab, plan to graft the front part of a Renault Trafic, or possible Ford Transit Custom, onto the frame (just the cab, not including drive, suspension, wheels etc). Using the already approved windscreen, doors, seats etc would help a lot in meeting local roadworthy/registration requirements.

There are lots of custom features in this, and whilst none of them are individually overly difficult, put together it is a huge amount of work. In the meantime I am going to improve the aero performance of my box shaped homebuilt camper/caravan! (some pics in here:

From Here to There | Around Aus)

For now, hopefully this discussion helps trigger design ideas for other people. Thanks to those who contributed and provided advise in the thread. If all goes well I'll revive it in several years time