Quote:

Originally Posted by stcyrwm

I am a little confused as to why you would do 12" thick walls though.

|

The depth allows for plywood or other rib/frame needed as the roof is all open, picture a pick-up truck bed that has a top flange - there is thickness otherwise the bed side would fold in. The alcoves between the spars would be for shelves or counters. I would have to draw this up for you to understand, it's not typical in any way.

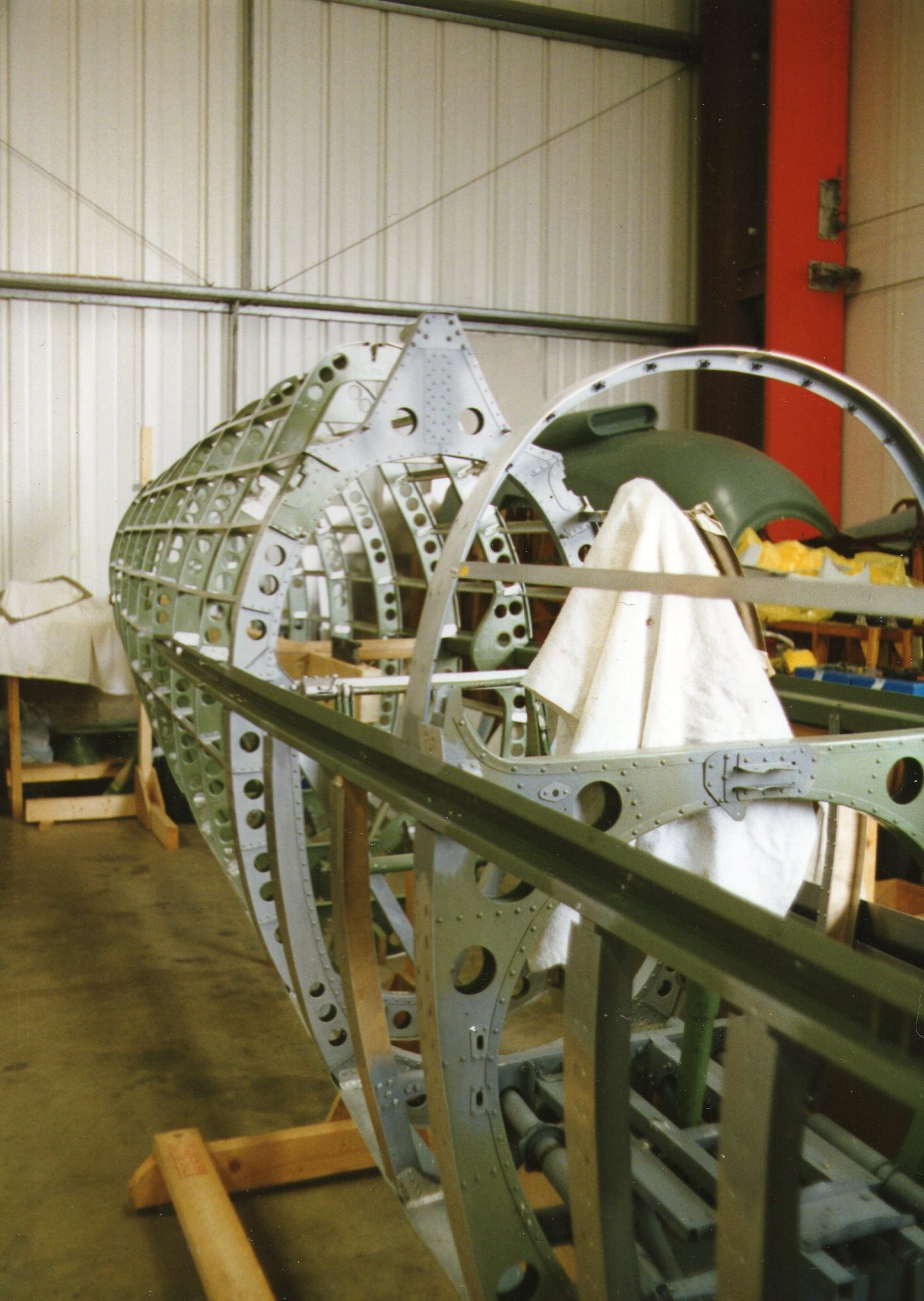

https://projectviper.wordpress.com/2014/08/

http://www.warbirdsonline.com.au/201...interior-view/

http://www.warbirdsonline.com.au/201...interior-view/

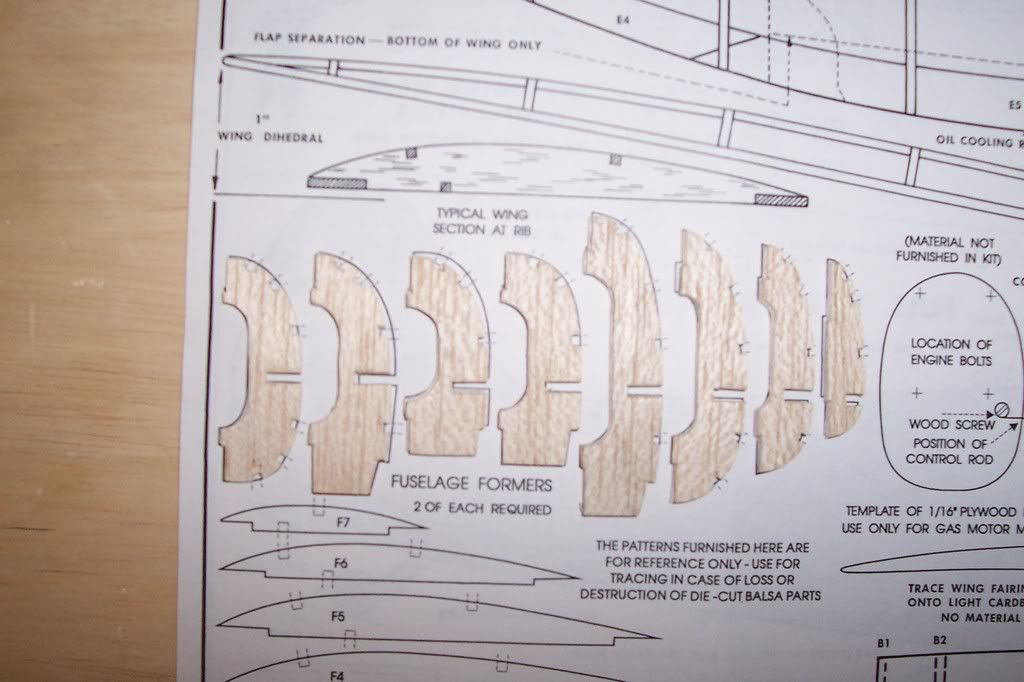

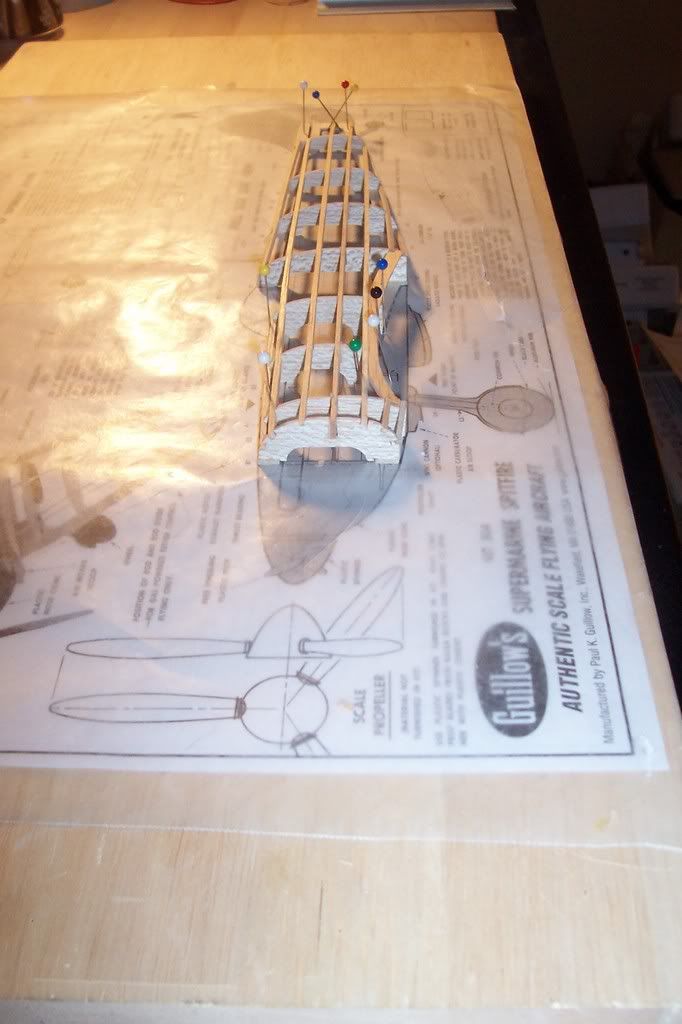

http://balsamodels.com/phpBB/viewtop...t=1288&start=0

http://balsamodels.com/phpBB/viewtop...t=1288&start=0

The above is similar to what I was trying to describe, WWII fighter style or balsa wood model construction. I built something similar when I was 15 years old, 36" wingspan balsa wood Spitfire -

it was glorious.

The storage trailer (

similar to horse trailer) I just looked at while doing a walk going from outside to inside is thin aluminum skin riveted (4-inches O.C.) to spars (2x2 wood or Z-metal) at 24" O.C. and plywood interior skin. The top edges all the way around are about 8" radius preformed aluminum quarter round channel with I think a flange or slot for the skin to be fastened to.

There was a damaged area, a hole in the side, no insulation in there and about a 2-inch depth.

This wood and metal hybrid construction is fairly common and I would suspect specialized parts could be purchased online somewhere.

EDIT:

Not too hard to find using "

trailer body round channel".

http://www.mirageinc.com/trailer-aluminum

In any case, wood on the outside is going to have serious maintenance issues. On the inside, wood takes abuse and impact, and gives you something to mount to. Better put some wood blocking behind it though.