02-13-2020, 02:02 PM

02-13-2020, 02:02 PM

|

#119 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 28,720

Thanks: 8,151

Thanked 8,935 Times in 7,377 Posts

|

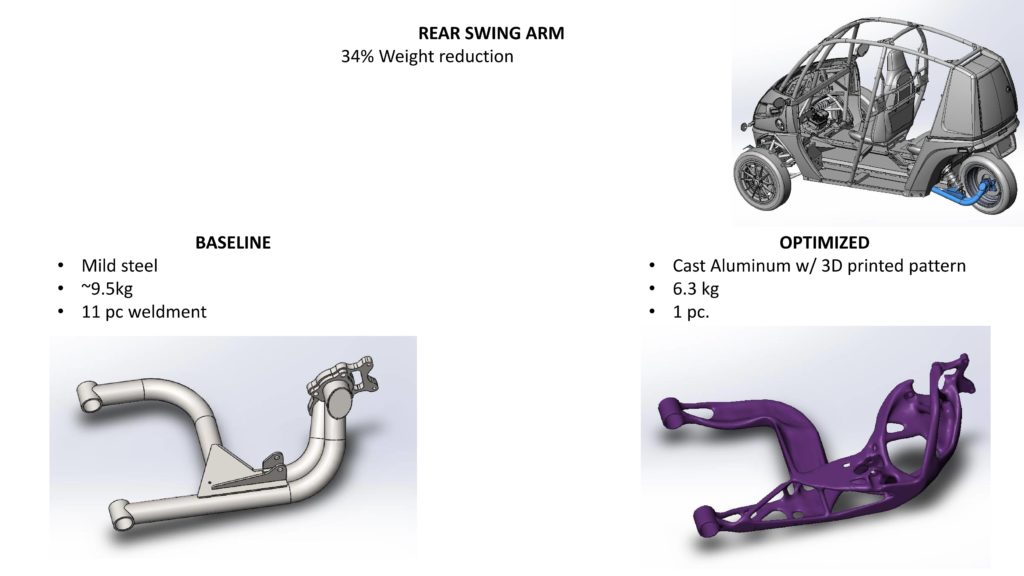

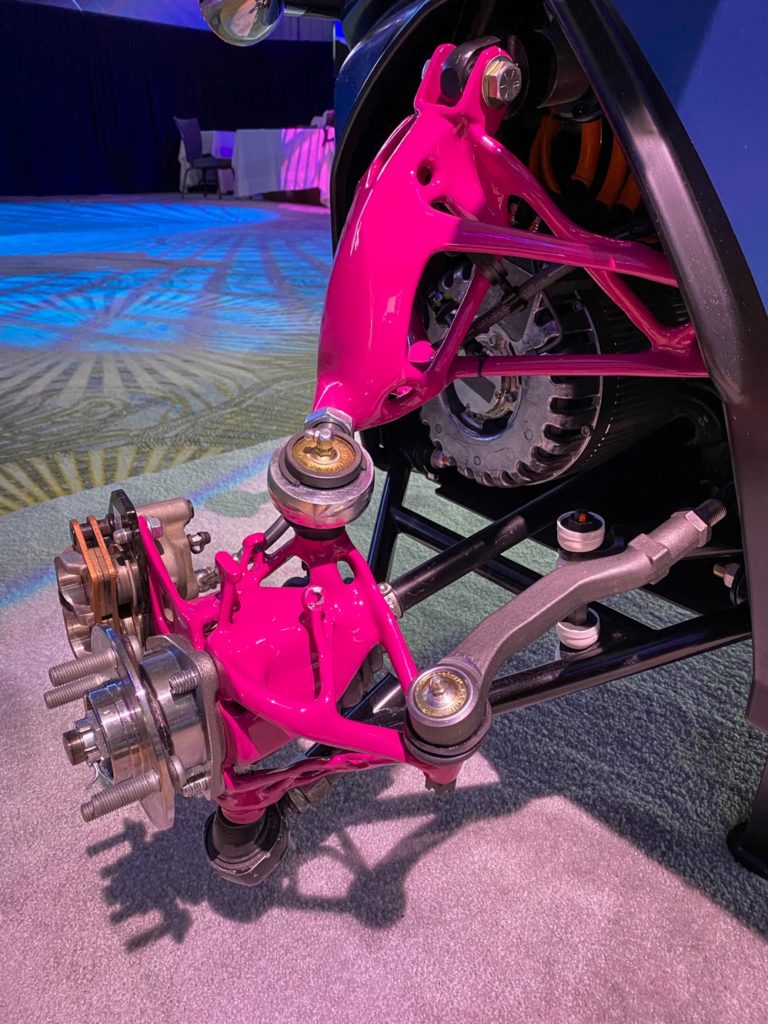

Meanwhile, back at The Whiteaker:

www.repairerdrivennews.com/2020/02/05/xponentialworks-project-produces-3d-printed-suspension-parts-for-aricimoto/

www.repairerdrivennews.com/2020/02/05/xponentialworks-project-produces-3d-printed-suspension-parts-for-aricimoto/

Quote:

“In response to your questions, once the component is designed the machines can print the part much quicker than a regular designed part (in a matter of hours) and with quantity comes efficiency of costs,” spokeswoman Oshy Ellman of Silicon Valley Communications wrote in an email.

The price also drops because less material is necessary, according to Ellman.

“The cost is reduced because one doesn’t use as much material as you would do with regular manufacturing,” she wrote in another email. “You also don’t spend time connecting many parts to create the bigger part. With 3D printing you can make one connected part (due to the complex structures) so a lot of time and effort is saved.”

Let’s say XponentialWorks and Arcimoto’s project goes the distance and finds a home on the retail FUVs now being produced. That means the 3D-printed suspension parts would be placed on an sub-$20,000 electric vehicle with a top speed of 75 mph and a range of 100 miles.

|

Note that this is all unsprung weight.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

____________________

.

.Three conspiracy theorists walk into a bar --You can't say that is a coincidence.

|

|

|

|