E-bikes often come with a torque sensor in the crankset that feeds a signal to the motor controller where the user can then choose the amount of pedal assist they desire.

These systems can be/are overridden by a std electric bicycle brake style throttle that could easily be integrated with the std foot throttle control in a car.

IMHO this is the easiest method of getting a DIY electric assist system to work with a ICE powered vehicle.

The sticking point for me has been the lack of 'bolt on' torque sensor.

These guys seem to have all the bases covered:

- Engine

- Transmission

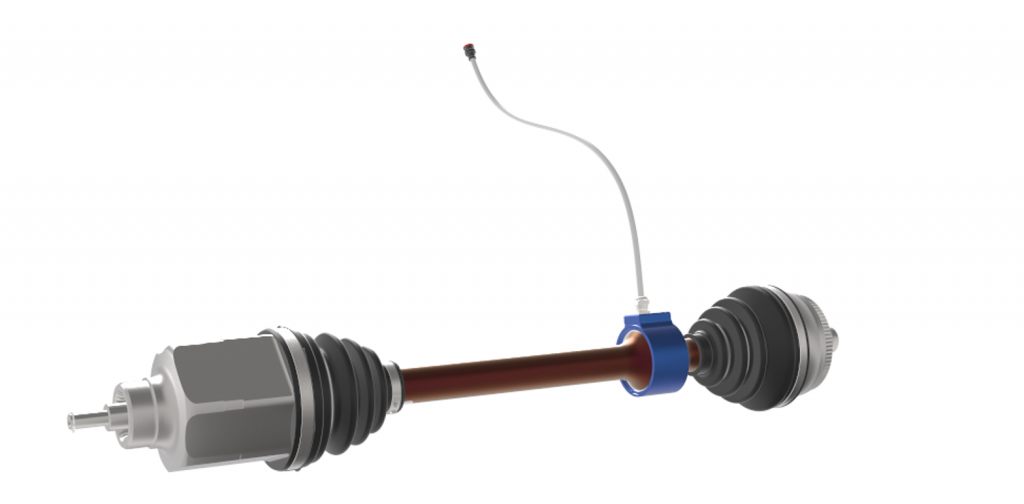

- Driveshaft

- Transfer case

- Differential

https://www.methodesensor.com/indust...orque-sensing/

Some Others:

https://binsfeld.com/torquetrak/markets/automotive/

https://binsfeld.com//shaft-strain-gaging-guide

https://melectric-systems.de/en/prod...%20Gelenkwelle

Amongst other things,

THE DRIVE SHAFT SYSTEM IS USED FOR:

- Evaluation of the aerodynamic efficiency of the vehicle

- The effectiveness of aerodynamic setup changes (e.g. roll-out tests, straight-ahead tests)

I hadn't considered that!

Then again, the supplier hasn't considered motor control.