OK all, I have a little question. The diodes will be surface mounted at this point. I need a good way to bend the legs to give them a little flex to handle the tiny expansion from heating. They will be clamped to the back of a heat spreader with about 15 pounds of force, so maybe the diodes will have a hair of ability to move if the legs get longer by like a micron or something from the heating? I've been bending them as follows:

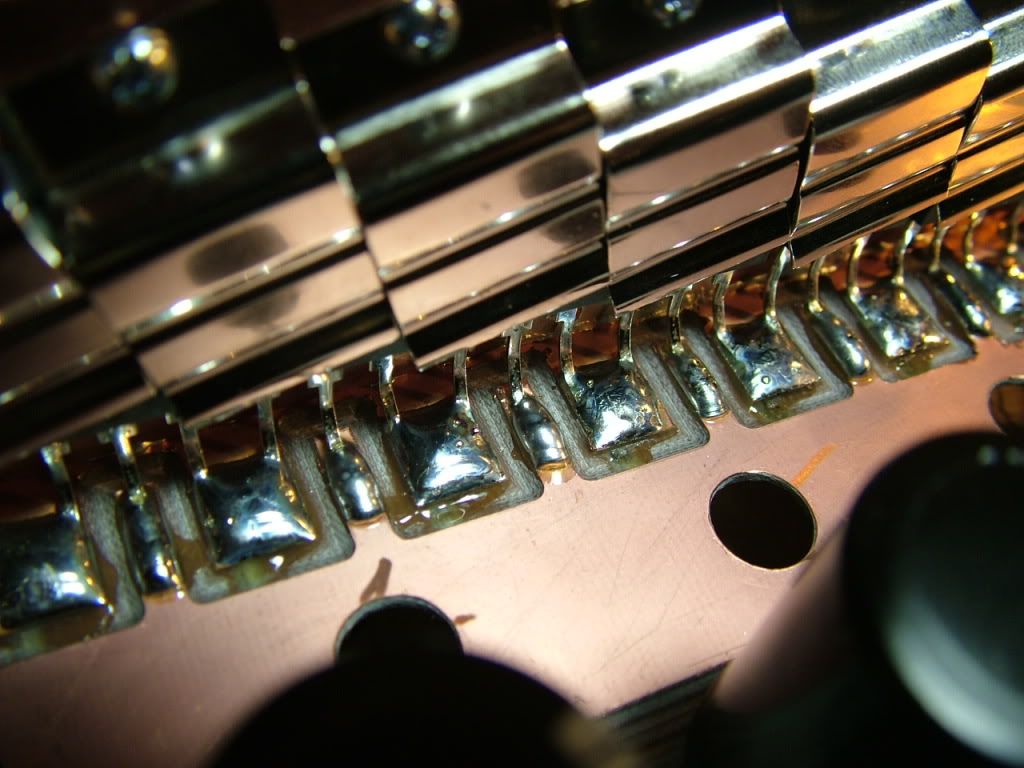

Here's what it looks like with the diodes soldered:

Ian of Zero Emissions Vehicles Australia does his like this:

That's a problem for me, since my middle bus bar is wider than his and the legs would bump into the bus bar. Oh the humanity. I could shave back the bus bar a bit I guess. What do you guys think?