Quote:

Originally Posted by jtgh

i never said one is better than the other, just pointing out facts few take in to consideration

- Electric conversion losses are the worst. (double conversion)

- noise

- heat.

- cost

- reliability (complexity is almost never the best solution )

|

You're wrong.

Quote:

Originally Posted by jtgh

do the math on the Alternator in series with the losses on the electric brush motor.

they are both very wasteful, and in series they are pathetic.

start with a drop of gasoline can work that to the spinning blade (you will not err)

if your car is in Arizona and you drive in bumper to bumper traffic. for hours.

it is ,in fact ,wasting way more energy, then a simple direct drive flex fan.

so consider where you live too. and driving predominance's.

|

LOL fantasy camp

Quote:

Originally Posted by dremd

Again all depends on the run time / run speed / conditions you operate in.

If you are a Las Vegas cab driver in the summer the Engine drive will be more efficient.

If your cooling fans run so rarely that you can't tell (until it hits 95F) when they fail (ME) the the electric will be much more efficient.

|

BINGO

Not to mention the fact that an electric fan attached to the radiator will ALWAYS be much more efficient at moving air than a fan attached to the engine. The distance from the fan blade face to the radiator and the distance from the fan blade tip to the shroud determine the efficiency of a fan at moving air. ALL mechanical fan (viscous clutch, mechanical clutch 'flex', fantasy camp BS, etc) are a disadvantage to a an electric fan in this respect. The mechanical fan has to have room in order to move around and vibrate to the engine. That means you always need at least a 1" gap between the tip of the fan blades and the edge of the shroud. I've seen mechanical fans set back 1-6" away from the back of the radiator as well. Any loses from converting mechanical power into electric energy pale in comparison to the inefficiencies of a mechanical fan running directly off the engine.

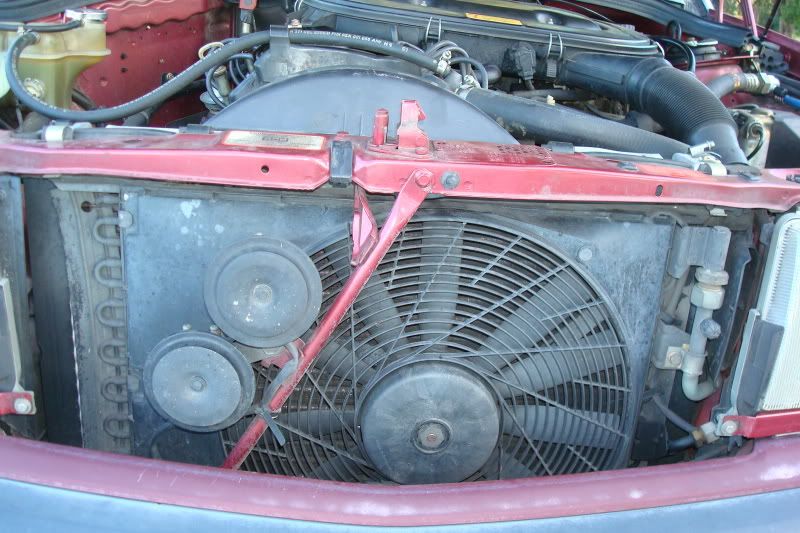

The white fan is the mechanical clutch fan I pulled off my Mercedes. The smaller electric fan in the upper right is the auxiliary factory fan mounted in front of the radiator. They were both replaced by the large electric fan on the left. The single large electric fan is substantially more efficient than the mechanical + aux stock fan setup.

Stock factory AUX fan. This fan would only turn on with the AC or if the stock clutch fan counted keep up. It consumed 10a on low, 20a, on high. It also had a really stupid shroud in front of the radiator that forced the system to only function through the fan. Shrouds are great behind the radiator, not so great in front. These cars have serious over heating issues in stock form.

I built a mounting bracket for the large single puller electric fan. The fan came out of a Volvo. Its a 2 speed fan. It consumes 15a on low, 25a on high. It is triggered by the stock temp sensors built into the engine.

Test fitting it to the radiator.

I used a piece of old weather stripping around the edges of the fan as a defacto shroud. I haven't had a chance to build a proper shroud yet but it doesn't seem to be an issue.

After the swap, the full frontal area of the radiator and condenser is exposed to oncoming air. In the winter can close off part of the grill to reduce the air intake area.

With the electric fan mounted.

After the swap the car can sit in stop and go traffic with the AC running and the coolant temp gauge well under 100c at 95f air temp. I've had it well over 105f in Sacramento summer traffic. Try doing that with the stock mechanical fan setup.

I've done this swap on 3 cars so far. A volvo 240, BMW 318i and The above 190e. The volvo and bmw originally had viscous clutch fan. Neither had overheating issues but they both picked up fuel economy after the swap. The Mercedes had an electromagnetic clutch fan from the factory. In stock form it didn't create any drag on the engine when it wasn't running like a viscous clutch fan but the system was never able to cool the engine over 90f with the AC running. in stop and go traffic. Over 90f you had to turn off the AC and suffer. Removing the stock shroud in front of the radiator also made the AC a lot colder especially when the car isn't moving.

Moral of the story: A properly designed electric cooling fan with curved blades (noise reduction), shroud and multiple speeds will ALWAYS be the most efficient option for both energy consumption and cooling.

cheers

Justin