11-11-2009, 01:01 PM

11-11-2009, 01:01 PM

|

#41 (permalink)

|

|

Banned

Join Date: Feb 2008

Location: california

Posts: 1,329

Thanks: 24

Thanked 161 Times in 107 Posts

|

Quote:

Originally Posted by jtgh

i never said one is better than the other, just pointing out facts few take in to consideration

- Electric conversion losses are the worst. (double conversion)

- noise

- heat.

- cost

- reliability (complexity is almost never the best solution )

|

You're wrong.

Quote:

Originally Posted by jtgh

do the math on the Alternator in series with the losses on the electric brush motor.

they are both very wasteful, and in series they are pathetic.

start with a drop of gasoline can work that to the spinning blade (you will not err)

if your car is in Arizona and you drive in bumper to bumper traffic. for hours.

it is ,in fact ,wasting way more energy, then a simple direct drive flex fan.

so consider where you live too. and driving predominance's.

|

LOL fantasy camp

Quote:

Originally Posted by dremd

Again all depends on the run time / run speed / conditions you operate in.

If you are a Las Vegas cab driver in the summer the Engine drive will be more efficient.

If your cooling fans run so rarely that you can't tell (until it hits 95F) when they fail (ME) the the electric will be much more efficient.

|

BINGO

Not to mention the fact that an electric fan attached to the radiator will ALWAYS be much more efficient at moving air than a fan attached to the engine. The distance from the fan blade face to the radiator and the distance from the fan blade tip to the shroud determine the efficiency of a fan at moving air. ALL mechanical fan (viscous clutch, mechanical clutch 'flex', fantasy camp BS, etc) are a disadvantage to a an electric fan in this respect. The mechanical fan has to have room in order to move around and vibrate to the engine. That means you always need at least a 1" gap between the tip of the fan blades and the edge of the shroud. I've seen mechanical fans set back 1-6" away from the back of the radiator as well. Any loses from converting mechanical power into electric energy pale in comparison to the inefficiencies of a mechanical fan running directly off the engine.

The white fan is the mechanical clutch fan I pulled off my Mercedes. The smaller electric fan in the upper right is the auxiliary factory fan mounted in front of the radiator. They were both replaced by the large electric fan on the left. The single large electric fan is substantially more efficient than the mechanical + aux stock fan setup.

Stock factory AUX fan. This fan would only turn on with the AC or if the stock clutch fan counted keep up. It consumed 10a on low, 20a, on high. It also had a really stupid shroud in front of the radiator that forced the system to only function through the fan. Shrouds are great behind the radiator, not so great in front. These cars have serious over heating issues in stock form.

I built a mounting bracket for the large single puller electric fan. The fan came out of a Volvo. Its a 2 speed fan. It consumes 15a on low, 25a on high. It is triggered by the stock temp sensors built into the engine.

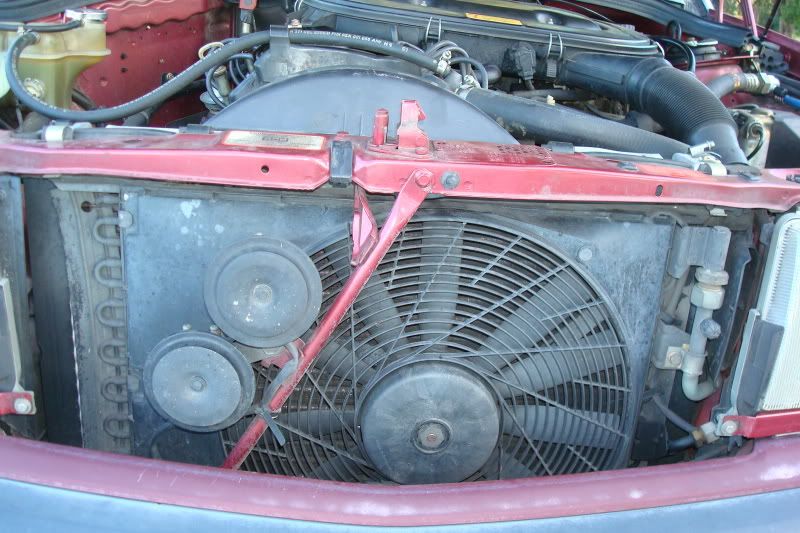

Test fitting it to the radiator.

I used a piece of old weather stripping around the edges of the fan as a defacto shroud. I haven't had a chance to build a proper shroud yet but it doesn't seem to be an issue.

After the swap, the full frontal area of the radiator and condenser is exposed to oncoming air. In the winter can close off part of the grill to reduce the air intake area.

With the electric fan mounted.

After the swap the car can sit in stop and go traffic with the AC running and the coolant temp gauge well under 100c at 95f air temp. I've had it well over 105f in Sacramento summer traffic. Try doing that with the stock mechanical fan setup.

I've done this swap on 3 cars so far. A volvo 240, BMW 318i and The above 190e. The volvo and bmw originally had viscous clutch fan. Neither had overheating issues but they both picked up fuel economy after the swap. The Mercedes had an electromagnetic clutch fan from the factory. In stock form it didn't create any drag on the engine when it wasn't running like a viscous clutch fan but the system was never able to cool the engine over 90f with the AC running. in stop and go traffic. Over 90f you had to turn off the AC and suffer. Removing the stock shroud in front of the radiator also made the AC a lot colder especially when the car isn't moving.

Moral of the story: A properly designed electric cooling fan with curved blades (noise reduction), shroud and multiple speeds will ALWAYS be the most efficient option for both energy consumption and cooling.

cheers

Justin

|

|

|

|

|

The Following 3 Users Say Thank You to tjts1 For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

11-11-2009, 07:05 PM

11-11-2009, 07:05 PM

|

#42 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,439

Thanks: 24,483

Thanked 7,412 Times in 4,802 Posts

|

C & d

Quote:

Originally Posted by Gregte

I just got done replacing the belt driven cooling fan on my GMC Sonoma with an electric fan, for the purpose of trying to save fuel. But after doing this I figured out a way to measure (guesstimate actually) the amount of fuel savings I might expect.

The electric fan draws 6 amps at 14 volts (84 watts). If one horsepower is 745 watts then the electric fan uses 0.11 horsepower. My electric fan seems to blow about as much air as the original mechanical fan. This suggests that the original fan was probably using about the same amount of power, which would be about 1% of the total cruising speed power used by the vehicle if cruising power used is around 11 HP.

Note, almost no energy is consumed by my electric fan because it is almost never running. In other words, this pickup rarely needs a fan at all under the conditions which I use it. So this is saying that I have removed the 0.11 horsepower robbing mechanical fan, with almost zero added energy deficit of the new fan.

I realize my method of measuring the energy expense of the original belt driven fan is a bit crude but I could not think of any better way to calculate it.

My question is, what are the opinions of others on how much fuel might be saved using an electric fan vs. mechanical, and how did you come up with your figures?

|

If went back to 1974 we might expect a 1/2 mpg improvement at 70-mph,as CAR and DRIVER experienced with their Crisis Fighter Pinto.

Much has changed since then,as Flex-fans,and viscous-coupled thermo sensitive drives replaced the fixed-fan drives of the early 70s.

It's quite possible to see only minor benefit now and personally,I'd be reluctant to make any sweeping claims. |

|

|

|

11-11-2009, 07:15 PM

11-11-2009, 07:15 PM

|

#43 (permalink)

|

|

Banned

Join Date: Feb 2008

Location: california

Posts: 1,329

Thanks: 24

Thanked 161 Times in 107 Posts

|

Quote:

Originally Posted by aerohead

If went back to 1974 we might expect a 1/2 mpg improvement at 70-mph,as CAR and DRIVER experienced with their Crisis Fighter Pinto.

|

C&D never installed an electric fan in that project.They cut off 2 fan blades for a 3% FE gain. What are you talking about?

Last edited by tjts1; 11-11-2009 at 07:24 PM..

|

|

|

|

11-12-2009, 04:48 AM

11-12-2009, 04:48 AM

|

#44 (permalink)

|

|

EcoModding Apprentice

Join Date: Jun 2009

Location: pacific southwest

Posts: 147

Thanks: 7

Thanked 4 Times in 3 Posts

|

Quote:

Originally Posted by jtgh

direct drive is the bench mark for 1:1 efficiency

|

hmmmmmmmmmmmmm!? i have seen some very sloppy crankshaft fan designs

poorly designed shrouds, air being sucked around the shroud, no shroud at all, huge radiator to fan distances and in most applications flat blades.

drag type blades VS air foils are terribly inefficient and noisy. finally airfoils are being implemented. you can HEAR the cars and trucks that don't have efficient cooling systems.

for comparative value: my 80s diesel VWs. no cooling fans. always run @ operating temp.

while we are on that subject...

the other side of the coin of direct drive fans are low ECTs while idling, during cold weather long downhills e.t.c. now THAT wastes fuel. and not just in diesels. |

|

|

|

11-13-2009, 04:48 PM

11-13-2009, 04:48 PM

|

#45 (permalink)

|

|

EcoModding Apprentice

Join Date: Jun 2009

Location: pacific southwest

Posts: 147

Thanks: 7

Thanked 4 Times in 3 Posts

|

Quote:

Originally Posted by jtgh

direct drive is the bench mark for 1:1 efficiency

|

hmmmmmmmmmmmmm!? i have seen some very sloppy crankshaft fan designs

poorly designed shrouds, air being sucked around the shroud, no shroud at all, huge radiator to fan distances and in most applications flat blades.

drag type blades VS air foils are terribly inefficient and noisy. finally on a few vehicles airfoils are being implemented - but the curved fan blades are helpful. you can HEAR the cars and trucks that don't have efficient cooling systems.

for comparative value: my 80s diesel VWs. no cooling fans. always run @ operating temp.

while we are on that subject...

the other side of the coin of direct drive fans are low ECTs while idling, during cold weather long downhills e.t.c. now THAT wastes fuel. and not just in diesels.

directdrive is cheap. not inexpensive but cheap. it is a way of always ensuring cooling when using a longitudinally mounted engine, which is best for the average consumer, and the least $$$ spent by the manufacturer. |

|

|

|

01-17-2010, 02:20 AM

01-17-2010, 02:20 AM

|

#46 (permalink)

|

|

EcoModding Lurker

Join Date: Jul 2009

Location: North Carolina

Posts: 77

Thanks: 0

Thanked 8 Times in 4 Posts

|

Just an FYI.....When I had my 2002 toyota tacoma I dyno'd it with and without the factory belt driven fan and saw a 7-8whp increase which was right at 10hp at the crank without the fan.....The power differential increased with rpms so it has a linear effect.....This means that when I was cruising at 60mph and 2k rpms I was saving approx 3whp.

|

|

|

|

07-09-2010, 12:38 PM

07-09-2010, 12:38 PM

|

#47 (permalink)

|

|

EcoModding Lurker

Join Date: May 2010

Location: lawton ok

Posts: 81

Thanks: 4

Thanked 10 Times in 8 Posts

|

After reading all five pages of this, the newb has a question. I understand it takes a little bit of gas to run an electrical device such as an electrical fan but surely it takes way more horsepower to run an engine mounted clutch fan. Even when the clutch fan is in "neutral" it still is 8 (my f150 truck) pounds of rotating mass. I imagine eight pounds of rotating mass takes weigh more energy to move than an electrically driven fan. Just my thoughts though.

|

|

|

|

09-08-2010, 12:34 PM

09-08-2010, 12:34 PM

|

#48 (permalink)

|

|

EcoModding Lurker

Join Date: Apr 2010

Location: South Dakota

Posts: 5

Thanks: 0

Thanked 1 Time in 1 Post

|

This has been a fun discussion thread. I used to run a "fan-away" all-mechanical centrifugal clutch between the belt-driven water pump shaft and its in-line supported radiator fan. The "fan-away" had, as I recall, three adjustable springs which pushed brake shoes against the inner driven cylinder. As that shaft's rpm increased, at a user-adjustable threshold those springs no longer held the brake shoes against the driven cylinder, releasing the fan load from the driven shaft. So when driving at constant highway speeds, you had the release-threshold rpm set low enough that the fan was not driven by engine power, unloading several horsepower of then-unneeded drag. At highway speeds, air flow generated by vehicle movement induced sufficient air flow to enable rejecting radiator heat. When you slowed down, you'd hear a little "squeal" as those little clutches bit against the drive cylinder's outer surface. This was back in the 1960s when I was occasionally participating in MPG contests.

Typical V-belt driving efficiency when fully warmed (yes, they are more efficient when warm and more flexible than when cold), can approach 97%. In-line concentrically-driven alternators, fans and other accessories don't need to pull that continual 3%-minimum efficiency loss.

Clearly the lowest power consuming way that's typically available to reject waste heat is with passively-generated air flow from vehicle movement. Adding radiator fan blades imposes some trade-offs. More driven blades can produce more air flow. More un-driven blades produces more air drag. So with more blades, passive air flow is reduced. Most road vehicle passengers dislike high fan noise levels. Yet from a purely-efficiency-judged intermittent use perspective, a 2-bladed high-speed fan seems to produce the best trade-off. When not driven, it imposes the least parasitic drag impeding passive air flow. When driven, 2-bladed props driven by equal power, spinning at higher rpms, generally are more efficient air movers than slower-spinning fans equally powered at lower rpms. But sounds like a small airplane preceding your vehicle in traffic with your Air Conditioning turned on would be an unacceptably high price to pay for the slight efficiency improvement compared to a higher-blade-count slower spinning fan.

While its obvious that powering no fan uses less energy than powering any fan, it seems reasonable to consider total fan-driving efficiency when they are being driven. Here, any of the best mechanically-driving systems are MUCH more energy efficient than electrically-driven systems. Let's assume for the moment that you compare two fan-driving systems which are as similar as possible except for their drive configurations. Same fan blade sets, same surrounds, just mechanical drive vs. electric drive. Nobody of whom I'm aware has been able to mechanically drive a radiator-cooling fan attached to crankshaft extension, perhaps with an in-line clutch to control when that parasitic load is added. So we have belt drives which can transmit about 97% of input energy to the driven shaft while converting about 3% to waste heat. Add your control clutch and fan. Someone's earlier speculation that spinning mass inherently converts input power to waste heat is simply wrong. Drag, not mass is how these systems loose energy.

By comparison, the first step in usual automotive electrically-driven fan systems is a belt-drive going to an alternator. Instantly multiply by 0.97 to account for that belt's losses. Then we have the ABYSMALLY low-efficiency claw-poll alternator which converts fully 50% of its input energy into waste heat. Perhaps you dropped $350 - $700 on a Permanent Magnet high-efficiency alternator as are becoming popular on big over-the-road trucks, and you are now talking about roughly 70% efficiency and only 30% being converted to waste heat. Or are you one of a handful who has a Polar Power alternator like those which performed so well in US Army tests producing 85% - 90% through-put efficiency and only converting 15% - 10% into waste heat. Some of us drive vehicles which cost less than one of those wonderful exotic alternators. Well over 99% of the on-the-road auto fleet run the usual bad-joke-efficiency claw-poll alternator configuration. So far we have 0.97 x .50 for power throughput on the electric fantastic. Let's assume you run sufficiently robust wiring that you have zero wiring system losses. That's not going to be true, but for a trivial 1% - 2% typical loss rate, we'll ignore wiring. But typical recent generation electric motors used to drive electric fans are 85% - 90% efficient. So the electrically driven system's crankshaft to fan-blade throughput efficiency prediction is at best the multiplied product of 0.97 x 0.5 x 0.9 = 0.4365. So a clean all-mechanical system can produce about 97% efficiency and the electrically driven system can produce about 44% efficiency WHEN DRIVEN.

The trick is to avoid driving those systems and just use passively-generated air flow.

Sorry to rupture some balloons, but totally ignoring required links in the power delivery chain is just silly.

John

|

|

|

|

|

The Following User Says Thank You to LoveLearn For This Useful Post:

|

|

09-08-2010, 03:08 PM

09-08-2010, 03:08 PM

|

#49 (permalink)

|

|

Human Environmentalist

Join Date: Aug 2010

Location: Oregon

Posts: 12,972

Thanks: 4,364

Thanked 4,530 Times in 3,482 Posts

|

Do people just remove the fan altogether? I suppose if one lived in a cooler climate and kept an eye on the temps a fan might not be needed. If the temps began to rise it could be mitigated by running the heater full blast.

I used to run the heater in my Volvo in the summer at full blast whenever it would begin to overheat. Would the gain in MPG justify the complete removal of the fan?

|

|

|

|

09-08-2010, 03:19 PM

09-08-2010, 03:19 PM

|

#50 (permalink)

|

|

(:

Join Date: Jan 2008

Location: up north

Posts: 12,762

Thanks: 1,585

Thanked 3,556 Times in 2,218 Posts

|

I removed the fan from my F150 a few years ago. At first I carried it and a wrench in the cab so I could put it back on if needed. Now the fan is hanging in the garage.

|

|

|

|

|