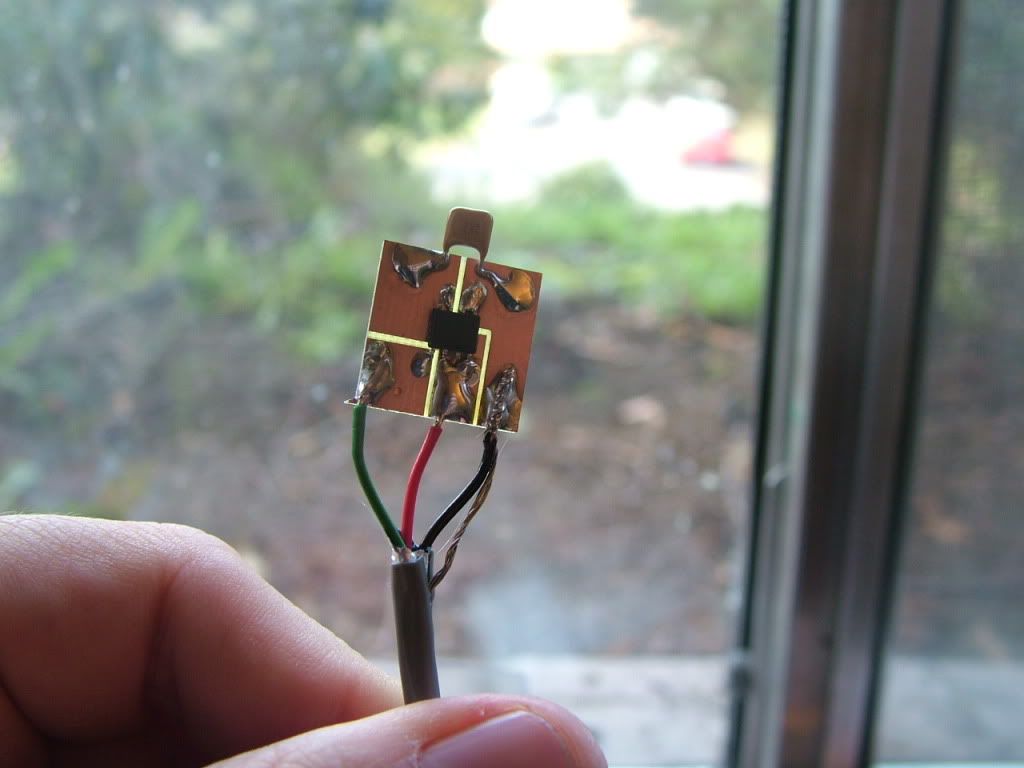

Here's a picture of the 1000amp current sensor.

The company actually uses these little 30amp sensors for measuring amps in the 1000s in applications! I heard it right from the mouth of the guy that wrote the pdf of the part. I got my mill all tuned up so it's about +/-0.001 accurate, so it's super easy to etch and cut out those little boards. I hate the soldering part on the stupid surface mount things though.

Hey John! What's the best, fanciest in the world material (that's cheap too hahahaha) for carrying the heat across 2 metal surfaces that are touching?

OK, now for the heat...

At 1000 amp, 100% duty, it would generate about 75 watts per mosfet (I guess a little more, due to switching losses). However, 100% duty and 1000amp would be very uncommon, since the 1000amp would usually only happen at very low rpm, which would mean very low duty.

Joe in Phoenix (a beta tester) saw his inside controller temps rise to about 65 degC when ambient was about 42-43 degC. That was with freeway driving I think. Maybe 150-200amp continuous I guess.

Honestly, I'm not sure how much heat it will have to dissipate. I don't know very much about this.

Maybe I'll add an "average energy useage" variable in the software for the last maybe 1 second, 10 seconds, 1 minute, etc... so that the 1000amp could be just occasional maybe. Like each time you want to take off from a light or whatever.