02-27-2010, 05:13 PM

02-27-2010, 05:13 PM

|

#3021 (permalink)

|

|

EcoModding Apprentice

Join Date: Feb 2010

Location: Northern Wisconsin

Posts: 137

Thanks: 32

Thanked 39 Times in 23 Posts

|

Quote:

Originally Posted by CamLight

Unfortunately, as I understand it, it can't be done DIY very well. It takes a lot of current and requires a very carefully controlled temperature bath.  Otherwise, it's pretty well the same process used for the colorful anodizing often seem. It's just a lot tougher. Half the hardcoat anodizing actually sinks into the pores formed by the acid bath (typically 1/2mil deep) and half sits on the surface (typically 1/2mil thick). What's on the surface forms the "insulation" and is incredibly tough. Do not plan to do any machining or drilling of a hardcoat anodized piece of alumunum! It will eat up your bits.

But, a large number of anodizing facilities can do Type III hardcoat anodizing (the military uses it a lot). The only problem is that it comes in only one color, dark gray/black. They typically charge a lot fee for a basket full of parts. The more parts you send in at a time, the less expensive it will be for each part.

If you don't have a lot of parts (100+), it can get expensive. But, if you're pushing the thermal envelope for a design and can't have a "hot" heat sink or use mica or thermal pads between the MOSFETs and heat sink (because of their high thermal resistance), hardcoat anodizing is the way to go. |

LOL yes you are right - but we have done it here Raceline Oil Pumps, manufacturing dry sump oil pumps and accessories for race engines.

I know because I worked on the DC supplies - and they do all the Type III in an old freezer with external pumps and cooling ( cooling is the key and great regulation of the current!) -- I guess DIY gets serious with some people.. It definitely is not as easy as the "anodize in a 5 gal bucket" with temp probes - but we all have done the impossible here - but CamLight is right - easier to find someone to do it...

__________________

Dave  ...

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

02-27-2010, 05:23 PM

02-27-2010, 05:23 PM

|

#3022 (permalink)

|

|

EcoModding Lurker

Join Date: Aug 2009

Location: New York City, USA

Posts: 23

Thanks: 0

Thanked 7 Times in 4 Posts

|

Quote:

Originally Posted by dave koller

|

Ahh...good points. I didn't mean to imply that no one should even attempt to do hardcoat anodizing.  Some of my stuff gets used by the gov't and military and they won't accept Type III done by anyone but a vendor who will certify their work and the thickness (which determines the voltage that it can stand off). That kind of rubs off on anything I recommend.

If there's someone who wants to DIY the hardcoating for a uber high-power controller heat sink, go for it! It's easy enough to put a high voltage across a test piece and check for current flow.

__________________

John M.

Owner

CamLight Systems

|

|

|

|

02-28-2010, 10:29 AM

02-28-2010, 10:29 AM

|

#3023 (permalink)

|

|

Tall Lurker

Join Date: Apr 2009

Location: CT

Posts: 17

Thanks: 0

Thanked 2 Times in 1 Post

|

Thanks to CamLight for the clearheaded Type III description.

But... if we're still talking about the power section of the controller, the goal is still to conduct 500A. (or 1000A.). It seems that the power section of the design may have a new configuration. Controlled MosFETs, electrically and thermally conducting in parallel through a buss bar, which is then cooled by an electrically isolated, thermally conductive member. Which sounds like the possibility for a very rugged chassis mounting scheme.

|

|

|

|

02-28-2010, 03:52 PM

02-28-2010, 03:52 PM

|

#3024 (permalink)

|

|

EcoModding Lurker

Join Date: Nov 2009

Location: Long Island, NY

Posts: 83

Thanks: 0

Thanked 9 Times in 9 Posts

|

I clicked on "pictures and albums" but then I didn't know what to do. I want to take the 8 files (schematics) from my flash drive and transfer them to the box. I told you I don't know the first thing about what I'm doing!!

|

|

|

|

02-28-2010, 05:59 PM

02-28-2010, 05:59 PM

|

#3025 (permalink)

|

|

EcoModding Lurker

Join Date: Aug 2009

Location: New York City, USA

Posts: 23

Thanks: 0

Thanked 7 Times in 4 Posts

|

Quote:

Originally Posted by chapper

Thanks to CamLight for the clearheaded Type III description.

But... if we're still talking about the power section of the controller, the goal is still to conduct 500A. (or 1000A.). It seems that the power section of the design may have a new configuration. Controlled MosFETs, electrically and thermally conducting in parallel through a buss bar, which is then cooled by an electrically isolated, thermally conductive member. Which sounds like the possibility for a very rugged chassis mounting scheme.

|

Ahh...so the FETs would be mounted on a bare (copper?) bus bar that would act as a heat spreader and also conduct the current out? And then the bus bar would be mounted to an electrically insulated heat sink to get rid of the heat?

What FET case type/size was selected for the high-amp configuration? Were they just going to be screwed or clamped against the bus bar (without a thermal transfer compound)?

__________________

John M.

Owner

CamLight Systems

|

|

|

|

02-28-2010, 06:11 PM

02-28-2010, 06:11 PM

|

#3026 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

I don't know about everyone else, but for my 1000amp attempt, I'm using TO-264 package 200v:

Digi-Key - IXFK230N20T-ND (Manufacturer - IXFK230N20T)

I like the idea of anodizing the heat spreader. Is it possible to anodize only part of something? Like the bottom 3/4 of it, so the top would still be copper or aluminum, and might carry the heat away a little better when it's in contact with the heat sink? |

|

|

|

02-28-2010, 06:26 PM

02-28-2010, 06:26 PM

|

#3027 (permalink)

|

|

EcoModding Lurker

Join Date: Aug 2009

Location: New York City, USA

Posts: 23

Thanks: 0

Thanked 7 Times in 4 Posts

|

Spectacular thermal resistance numbers for that FET! I use IXYS FETs for my electronic loads and they've worked wonderfully at continuous operation above 140C. I didn't check the gate charge numbers but you controller guys know a LOT more about that than I do. My loads use FETs biased in their linear region and a gate charge as high as one farad wouldn't even be a problem!

You can mask off areas, and only selectively apply the anodizing, but the anodizing has so little an effect on the thermal resistance of the metal-to-metal interface that it's usually not worth the extra cost for the masking.

[Edit] Just a note...you can only anodize aluminum. I'm not aware of any insulating method for copper that has a low thermal resistance.

To carry the heat away, you'll definitely will need a thermal transfer compound or material though. Metal-on-metal contact has a very high thermal resistance due to the very low surface area of the metal that's actually touching. The micro hills/valleys need to be filled in by a compound or pad....preferably compound. All depends on the power you have to move though. 5W, no problem with only metal-on-metal. 50W, big, big problem without compound.

How many watts of heat do you estimate each FET will have to dissipate?

LOL, sorry about all the design questions. I'm just fascinated with high-power thermal-transfer design and it always leads to lots of questions.

__________________

John M.

Owner

CamLight Systems

|

|

|

|

02-28-2010, 06:59 PM

02-28-2010, 06:59 PM

|

#3028 (permalink)

|

|

PaulH

Join Date: Feb 2008

Location: Maricopa, AZ (sort of. Actually outside of town)

Posts: 3,832

Thanks: 1,362

Thanked 1,202 Times in 765 Posts

|

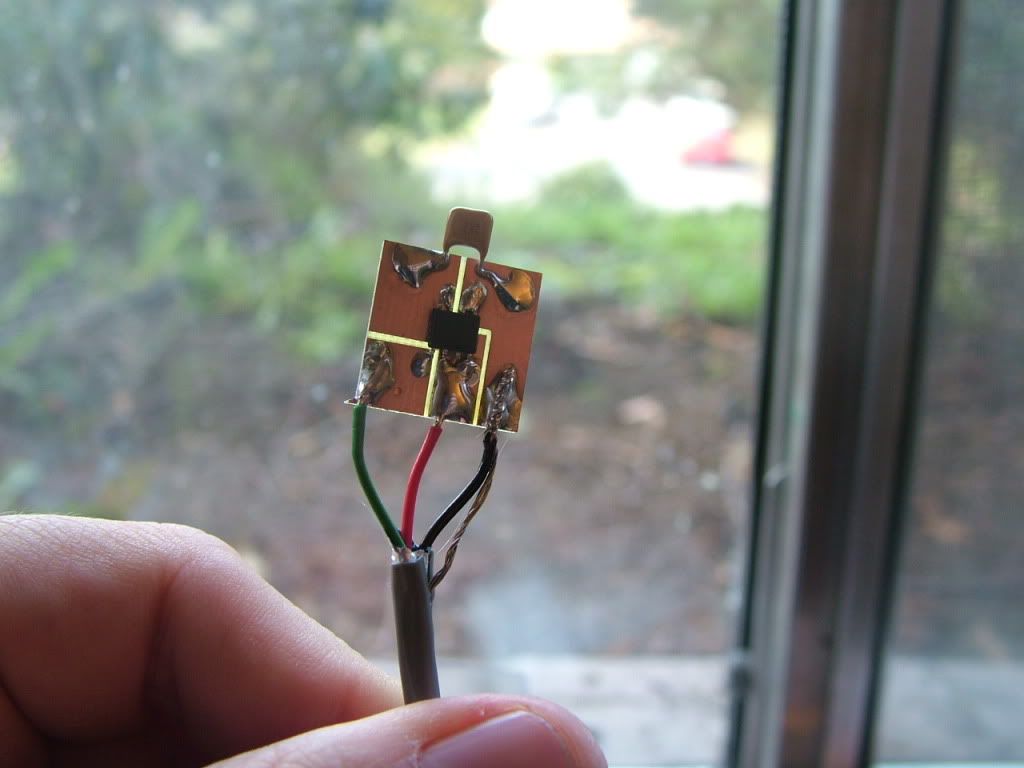

Here's a picture of the 1000amp current sensor.

The company actually uses these little 30amp sensors for measuring amps in the 1000s in applications! I heard it right from the mouth of the guy that wrote the pdf of the part. I got my mill all tuned up so it's about +/-0.001 accurate, so it's super easy to etch and cut out those little boards. I hate the soldering part on the stupid surface mount things though.

Hey John! What's the best, fanciest in the world material (that's cheap too hahahaha) for carrying the heat across 2 metal surfaces that are touching?

OK, now for the heat...

At 1000 amp, 100% duty, it would generate about 75 watts per mosfet (I guess a little more, due to switching losses). However, 100% duty and 1000amp would be very uncommon, since the 1000amp would usually only happen at very low rpm, which would mean very low duty.

Joe in Phoenix (a beta tester) saw his inside controller temps rise to about 65 degC when ambient was about 42-43 degC. That was with freeway driving I think. Maybe 150-200amp continuous I guess.

Honestly, I'm not sure how much heat it will have to dissipate. I don't know very much about this.

Maybe I'll add an "average energy useage" variable in the software for the last maybe 1 second, 10 seconds, 1 minute, etc... so that the 1000amp could be just occasional maybe. Like each time you want to take off from a light or whatever. |

|

|

|

02-28-2010, 08:50 PM

02-28-2010, 08:50 PM

|

#3029 (permalink)

|

|

Tall Lurker

Join Date: Apr 2009

Location: CT

Posts: 17

Thanks: 0

Thanked 2 Times in 1 Post

|

From CamLight (#3035)

Ahh...so the FETs would be mounted on a bare (copper?) bus bar that would act as a heat spreader and also conduct the current out? And then the bus bar would be mounted to an electrically insulated heat sink to get rid of the heat?

Precisely! Sketch is on the way... probably tomorrow.

|

|

|

|

02-28-2010, 08:51 PM

02-28-2010, 08:51 PM

|

#3030 (permalink)

|

|

EcoModding Lurker

Join Date: Aug 2009

Location: New York City, USA

Posts: 23

Thanks: 0

Thanked 7 Times in 4 Posts

|

Nice sensor setup! May have to use that one for a 1100A load I'm working on for a client this Spring.

I did a lot of research on the available thermal transfer compounds as I was really pushing the limits on how much heat can be moved out from a small volume. I picked Aavid's UltraStick phase-change compound as my #1 choice and have been very, very happy with it. It's a soft wax at room temperature but when warmed it turns to water consistency to flow and fill in every single micro-pocket in the metal. Going that runny also allows the FET to press against the metal as tight as possible. Ideally, you want absolutely no compound between the two component's high points of contact. You only want he compound filling in the low points to increase the surface area that's touching. When you remove the FET, the compound should be practically invisibly thin, ideally down to 0.1mils thick.

Digikey carries UltraStick ( DigiKey Corp. | Electronic Components Distributor | United States Home Page) for about $21 a stick. But that stick will do hundreds, if not thousands, of FETs.

[Edit] To compare to other compounds and thermal pads, the thermal resistance of UltraStick with a TO-264 FET was about 0.017C/W....very low. The very good silicone compound I tested (Wakefiled Type 126) was about 0.03C/W. But, as mentioned below, the darn oil evaporated at the high temps the FETs were operating at, 140C junction, and condensed onto everything nearby in the circuit. A real mess.

I don't recommend the silicone thermal compounds as the silicone oil separates out when heated and the compound goes dry over time...very bad. Also, at the very high temps this controller will see the oil can actually evaporate and condense on nearby (cooler) components...also very bad. Lastly, the oil can flow onto components when hot too if too much is used. The stuff is inexpensive, but not a great choice for some applications.

65C internal ambient temperature? Let's do some math.

That IXFK230N20T FET has a junction-to-sink thermal resistance of 0.24 degrees-C/W. That means the temperature of the MOSFET's junction (the important part) will be ((Wattage) x (0.24)) degrees-C higher than the temp of the heat sink directly behind the FET's "rear" metal plate. If the FET is dissipating 75W, then the junction is 18C hotter than the sink temp directly behind it.

Assuming that a very good sink has a sink-to-ambient thermal resistance of 0.5C/W, then the total thermal resistance from the junction of the FET to ambient air is 0.24 + 0.50 = -.74C/W. If that one FET was on its own sink and dissipating 75W, then it would be operating at (75W) x (0.74C/W) = 56.25C hotter than ambient. Assuming that 65C ambient you mentioned, that's 65C + 56C = 121C junction temperature. That's a hot FET! But, well within its rated max of 175C and even below the "high reliability" max temp rating, which is 80% of the rated max.

But, it shows how easy it is for a FET to be practically glowing from heat even though the ambient air is cool and even if the heat sink is cool. This also all assumes that the heat sink is both very flat and very smooth and that the MOSFET is mounted well to the sink and a good thermal compound is used.

It can be a bit dizzying at first but a few rough calculations can really help to make a unit a controller a lot more reliable or properly sized without wasting weight or space.

As you get closer to the final design (heat sink, # of FETs, average current, max current you want it to survive, etc.), I'd be happy to crunch a few numbers. Then some quick tests of the temperature of the FET's case in the prototype will tell you the FET's junction temperature and could give you a good idea of how you might want to limit the throttle duty cycle or timing in software (or modify the cooling system design)?

__________________

John M.

Owner

CamLight Systems

Last edited by CamLight; 02-28-2010 at 09:00 PM..

|

|

|

|

|

The Following 3 Users Say Thank You to CamLight For This Useful Post:

|

|

|