Thanks.

Well, I'll "keep up the work". There's bound to be some debate about whether it's "good work" or not.

But I'm having fun!

----

OK, some photos... Prepare to be amused!!

Above: the component parts of the test coupler v.1.0:

- wood to go over the input shaft

- the slotted disc is the hub from inside the power steering pump (the slots used to hold the pump vanes)

- the removable pump shaft to the motor (note pesky keyway style interface to the motor)

Yes, the pump hub is nailed to the wood.

So far that part has been the LEAST trouble!

Above: change of plans... instead of trying to clamp it on, four screws are set into the slots between the input shaft splines. More positive connection.

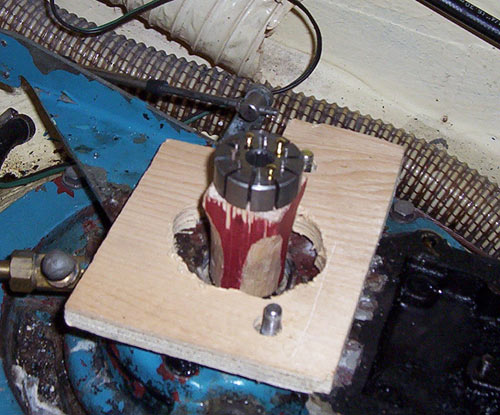

Above: shaft & coupler installed in transmission & base plate for the (wood.. of course) motor mount.

Ready to go!

Gone!

The mechanical connection to the input shaft was so good that the failure point became the wood. It worked fine on 12 volts. But when I started up at 24 volts (from rest), the wood split in 3 places.

---

Since taking these pics, "work" has continued. I modified and tested coupler v.1.1 last night. It worked great ... until it failed. (Lasted many seconds longer than the first version though.)

Version 1.2 will be tried tomorrow.

I'm almost ready to invest in a metallic coupler - I hear they're all the rage these days.