How to make Polycarbanite Clear Wheel Skirts/Kilts:

I used 1/16 thick polycarb.

It tended to vibrate when trucks whent by so on the second set I added a small aluminuum flat bar the distance of the bottom edge and achored at the fender wells.

1. The biggest concern I had was connecting the skirt to the fender wheel arce. I was not going to tape it, nor drill it, nor alter or damage the paint. THe key was the connecting part.

I had just installed a 9 inch and a 7 inch aftermarket cooling fans. The fans come with a "L shaped" part that I didn't use. on examining the part, I saw it had a 'catch' that could hook on to the lip of the fender well:

if you look close you can see the notch.

here is the part hooked into the lip. no screws, no drilling.

2. Now that I found a satisfactory meth to attch to the car, I bought nylon nuts and bolts to attch the skirt to the L part:

I epoxied the nut onto the L part so I don't have to stick my hand up under the sskirt tio trighten or lossen. One of my smarter moves in the last 3 months!!!

2. Next step is to get a templet of the opening. depending on the space, you may not have to remove the tire. you want to trace the lip of the wheel well from the inside, onto a sturdy surface.

3. Polycarbonite is flexible and strong. I don't think that the matreial at the home depot is polycarb. PC is not brittle so it wont crack.

4. I cut the skirt/kilt a little oversize so it would press against the car fender. The 3 L parts don't come out flush so the nylon bolt is pulling the l part to hang on to the fender lip AND pressing the skirt against the fender.

5. I had some other clips the I used at the bottoms.

THe trick at the to bottom corners is to create a curve in the PC that keeps the PC curved away from the tire and still sealed along the body.

The metal L brackets a at about 110 degrees. Not at 90 dregrees. this forces the PC to curve.

RTHe hole is a little father uot than if the PC was laying flat. This forces the curve. You don't want TOO much arch or curve. You are just barely trying to clear the tire.

IF you don't have an arch, then the PC will 'flap' in the center when a large truck goes by, becaUSE of the air turbulance.

(TRUST ME ON THIS!!!!) That is the reason you see the second hole in the picture.

this is the driverside rear of skirt:

here is the front of the driver's side skirt:

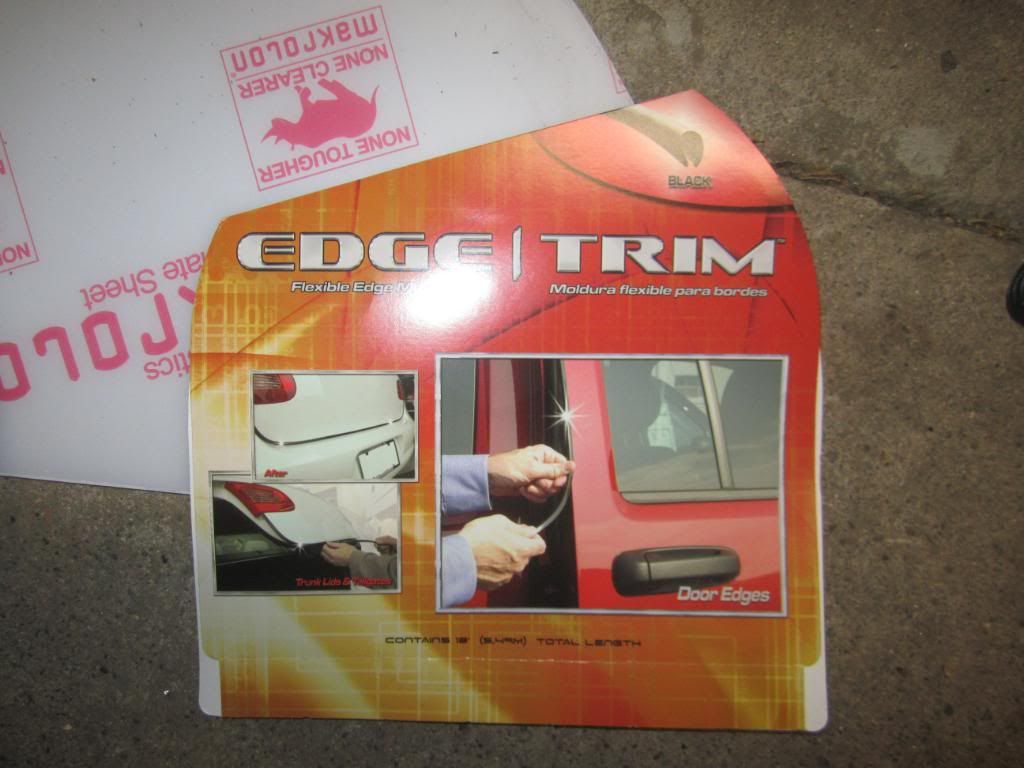

To keep the PC from scratching the paint, I got this product at the auto parts store:

I am going to cover the nylon bolt heads w/ licence plate bolt covers:

Initially, I thought I needed a rigid bottom piece to frame the PC and cover the distance. I had made a bottom usung a channel piece of acrilyc. Didn't need it. It wasn't flexible eough.

This was the first version (no curve):

there was too much 'finish work' needed to close the skirt to the fender.

Polycarbonite comes with a protective film on both sides. i used a power jig saw to cut the shape. leaving the protective film on eleminated schratches.

you can see the protective film on the inside of the skirt/kilt in this picture.

Because the PC is more flexible than I first thought it woud be, I was able to eleminate the need for the bottom chanel.

I will probably make another set that sactually go down lower.

I will get the thickness of the polycarbonite. It comes in acouple of thicknesses that would be suitable.

Again, the issue is the flapping or popping back and forth of the center when there is excessive wind or turbulance.

a thin piece of flat steel or alluminuum could be mounted between the two bottom attaching points to dramaticly reduce the popping.

THe popping has not happened below 50 mph