01-24-2012, 12:37 AM

01-24-2012, 12:37 AM

|

#8 (permalink)

|

|

Master EcoModder

Join Date: Jul 2009

Location: New York

Posts: 513

Thanks: 2

Thanked 101 Times in 74 Posts

|

no --- use a used MAF sensor

reading further down in this thread some have suggested measuring flow in the hi pressure injector lines

do not do that

you can measure flow in the supply line then subtract

measured flow in the return line

both are low pressure

which is not very practical but there will be none of the problems that will arise from an attempt to measure high pressure pulsed flow

air fuel ratio is not controlled so measuring incoming air will not help , but measuring incoming air flow can give you a relative value that you can minimize to maximize FE

you can use a MAF sensor that can be plumbed into your intake all you need is a 5 volt supply and a ground on a hitachi type MAF which were / are readily available

and you can put a scope on the MAF output and measure flow per cylinder

relative flow

all must be the same exact signature , you can easily pick off dirty valves or low compression or contributing cylinders

Quote:

Originally Posted by BurningDinosaurBones

Can this work with my 1993 VW Golf Turbo Diesel? It has a belt driven mechanical fuel pump, throttle, and fuel injection system so there is no electrical involved in the fuel injectors as far as I know...

|

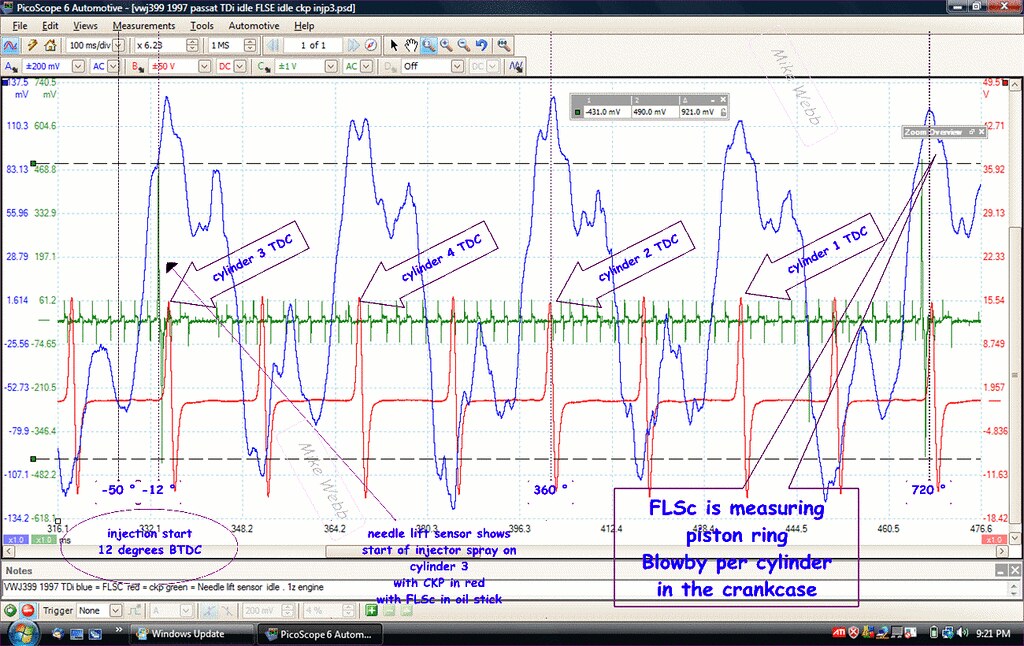

there is a later VW ALH engine at idle TDi engine, the green trace is a needle lift sensor on injector #3 , used to determine injector pump timing relative to the crankshaft which the red trace

there is a later VW ALH engine at idle TDi engine, the green trace is a needle lift sensor on injector #3 , used to determine injector pump timing relative to the crankshaft which the red trace

the pizeo input "Needle lift sensor " is as usable for rpm as the crankshaft sensor waveform

or

a sensor near the flywheel teeth

blue

another pressure differential sensor measuring pressure change in the crankcase , blowby from the piston rings , all are uniform , good

Last edited by mwebb; 01-24-2012 at 12:49 AM..

Reason: ALH w Needle lift and ckp

|

|

|

|