01-16-2012, 12:26 AM

01-16-2012, 12:26 AM

|

#1 (permalink)

|

|

EcoModding Lurker

Join Date: Jan 2012

Location: New Brunswick, Canada

Posts: 27

Thanks: 5

Thanked 1 Time in 1 Post

|

MPGuino my 1993 VW Turbo Diesel?

Can this work with my 1993 VW Golf Turbo Diesel? It has a belt driven mechanical fuel pump, throttle, and fuel injection system so there is no electrical involved in the fuel injectors as far as I know...

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

01-16-2012, 02:25 PM

01-16-2012, 02:25 PM

|

#2 (permalink)

|

|

Master EcoModder

Join Date: Dec 2007

Location: Southern California

Posts: 1,490

Camryaro - '92 Toyota Camry LE V6 90 day: 31.12 mpg (US) Red - '00 Honda Insight Prius - '05 Toyota Prius 3 - '18 Tesla Model 3 90 day: 152.47 mpg (US)

Thanks: 349

Thanked 122 Times in 80 Posts

|

You will need something to translate fuel use into a signal for the system to pick up. There's been talk of using two devices that measure flow, but those are kind of inaccurate from what I've heard I think using a TPS to measure throttle position would be more accurate, but it would also be harder because I don't think throttle position versus fuel injected is linear, so someone would have to include some programming that could guesstimate what kind of function it followed based on the TPS data and fillups, kinda like calibration with a SG.

|

|

|

|

01-16-2012, 03:28 PM

01-16-2012, 03:28 PM

|

#3 (permalink)

|

|

needs more cowbell

Join Date: Feb 2008

Location: ÿ

Posts: 5,038

Thanks: 158

Thanked 269 Times in 212 Posts

|

yah that is about it. With just throttle position and rpm I think it is doable, but one needs to map out fuel flow at various permutations of those parameters to accurately track fuel consumption, and it can change if you change the smoke screw setting (and as the pump wears).

So if you can hook the pumps/injectors up on the bench and point the injector(s) into a beaker, add tps and rpm signal, and take maybe 100 readings (10 throttle positions at 10 rpms) and chart that out to fuel flow, that would be one way. Then build the map into the chip and read the same tps and pump rpm and interpolate the fuel flow and etc.

Another approach discussed is sensing the fuel pulse length (piezo?), and injected quantity is then a function of RPM, pretty much.

__________________

WINDMILLS DO NOT WORK THAT WAY!!!

|

|

|

|

01-16-2012, 09:34 PM

01-16-2012, 09:34 PM

|

#4 (permalink)

|

|

MPG Militia HMV-25E80+A

Join Date: Mar 2011

Location: Vermont, USA

Posts: 823

Thanks: 191

Thanked 144 Times in 98 Posts

|

This interests me, also, as I'll be exchanging my 1.8 gas to a 1.6 diesel and already have an MPGuino. Is there a pressure switch that could be put inline with the injector lines?

|

|

|

|

01-21-2012, 10:41 AM

01-21-2012, 10:41 AM

|

#5 (permalink)

|

|

EcoModding Lurker

Join Date: Jan 2012

Location: New Brunswick, Canada

Posts: 27

Thanks: 5

Thanked 1 Time in 1 Post

|

I was thinking about my history working in industry. It's fairly simple if you want to determine a flow to just call the instrumentation department and get them to install a flow meter on a (fuel) line, then use the output against other variables to calculate whatever you want with it. It would be nice if there were a flow meter available for our cars, then you could just grab the output and plug into the mpguino, if that's possible? I know next to nothing about mpguino. But I was looking at the injectors the other day and each injector seems to have a return line coming out of it, meaning some of the flow going into the injectors may get returned to the fuel pump. So in that case you would need to have two flow meters, one for the flow to the injectors, and one for the flow out, subtract the signals from each other and use that as your fuel flow. Easy right. But I am brand new to diesels so maybe one line is for idling and the other is for acceleration? Who knows? Who can point us to this theoretical flow meter?

All of this manual calibration sounds like a whole lot of work to me. The ease of just plug and go of the scan gauge to the 96+ vehicles is more my style.

To me it seems easier to make a fuel cell like they use for fuel efficiency testing on myth busters. Weigh the cell before you leave, then weigh it after. Calculate your MPG. Test a route driven with different driving styles, compare results. There are only a few situations that I am curious about and this would seam like a good way of testing them. Once you figure out how to drive with the least fuel use on each route, drive accordingly in the future knowing that you are at maximum efficiency.

|

|

|

|

01-21-2012, 12:32 PM

01-21-2012, 12:32 PM

|

#6 (permalink)

|

|

EcoModding Lurker

Join Date: Jan 2012

Location: Knoxville TN

Posts: 96

Thanks: 1

Thanked 11 Times in 8 Posts

|

is there a flow meter that will work at 150 bar and beyond? I have seen some piezoelectric sensors that will clamp on a diesel fuel line that senses the fuel pulse to determine RPM, but never have seen an inline sensor after a diesel pump with fuel flowing thru it. However, that doesn't mean it does not exist

|

|

|

|

01-21-2012, 10:15 PM

01-21-2012, 10:15 PM

|

#7 (permalink)

|

|

needs more cowbell

Join Date: Feb 2008

Location: ÿ

Posts: 5,038

Thanks: 158

Thanked 269 Times in 212 Posts

|

yah, the clamp on piezo sounds like it can give you both rpm and pulse length and be easy to install, but it is a bit of signal processing to code or hardwire to make sense of it, and newer tdi use lots of little pulses which really ramp up the resolution demands on the cpu.

Older mechanical pump diesels certainly could use such a system, but if there is a computer adjusting the line pressure or making really tiny pulses it can get tricky.

__________________

WINDMILLS DO NOT WORK THAT WAY!!!

|

|

|

|

01-24-2012, 12:37 AM

01-24-2012, 12:37 AM

|

#8 (permalink)

|

|

Master EcoModder

Join Date: Jul 2009

Location: New York

Posts: 513

Thanks: 2

Thanked 101 Times in 74 Posts

|

no --- use a used MAF sensor

reading further down in this thread some have suggested measuring flow in the hi pressure injector lines

do not do that

you can measure flow in the supply line then subtract

measured flow in the return line

both are low pressure

which is not very practical but there will be none of the problems that will arise from an attempt to measure high pressure pulsed flow

air fuel ratio is not controlled so measuring incoming air will not help , but measuring incoming air flow can give you a relative value that you can minimize to maximize FE

you can use a MAF sensor that can be plumbed into your intake all you need is a 5 volt supply and a ground on a hitachi type MAF which were / are readily available

and you can put a scope on the MAF output and measure flow per cylinder

relative flow

all must be the same exact signature , you can easily pick off dirty valves or low compression or contributing cylinders

Quote:

Originally Posted by BurningDinosaurBones

Can this work with my 1993 VW Golf Turbo Diesel? It has a belt driven mechanical fuel pump, throttle, and fuel injection system so there is no electrical involved in the fuel injectors as far as I know...

|

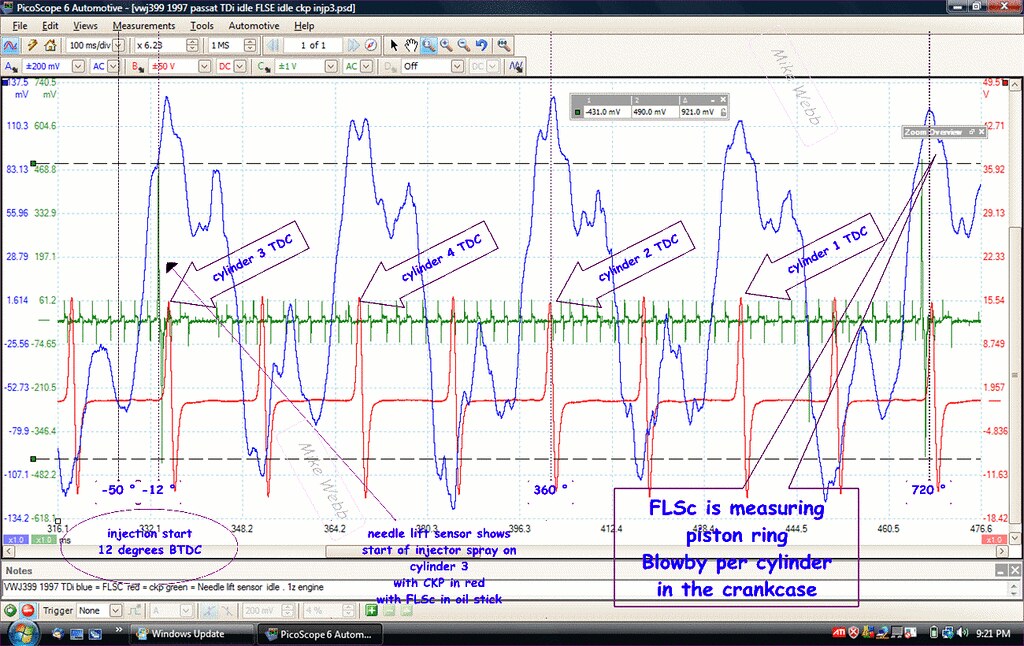

there is a later VW ALH engine at idle TDi engine, the green trace is a needle lift sensor on injector #3 , used to determine injector pump timing relative to the crankshaft which the red trace

there is a later VW ALH engine at idle TDi engine, the green trace is a needle lift sensor on injector #3 , used to determine injector pump timing relative to the crankshaft which the red trace

the pizeo input "Needle lift sensor " is as usable for rpm as the crankshaft sensor waveform

or

a sensor near the flywheel teeth

blue

another pressure differential sensor measuring pressure change in the crankcase , blowby from the piston rings , all are uniform , good

Last edited by mwebb; 01-24-2012 at 12:49 AM..

Reason: ALH w Needle lift and ckp

|

|

|

|

|

The Following User Says Thank You to mwebb For This Useful Post:

|

|

05-16-2014, 02:28 PM

05-16-2014, 02:28 PM

|

#9 (permalink)

|

|

EcoModding Apprentice

Join Date: Oct 2008

Location: Chile

Posts: 223

Thanks: 15

Thanked 9 Times in 7 Posts

|

Using rpm and tps for determining fuel used in real time

Quote:

Originally Posted by BurningDinosaurBones

I was thinking about my history working in industry. It's fairly simple if you want to determine a flow to just call the instrumentation department and get them to install a flow meter on a (fuel) line, then use the output against other variables to calculate whatever you want with it. It would be nice if there were a flow meter available for our cars, then you could just grab the output and plug into the mpguino, if that's possible? I know next to nothing about mpguino. But I was looking at the injectors the other day and each injector seems to have a return line coming out of it, meaning some of the flow going into the injectors may get returned to the fuel pump. So in that case you would need to have two flow meters, one for the flow to the injectors, and one for the flow out, subtract the signals from each other and use that as your fuel flow. Easy right. But I am brand new to diesels so maybe one line is for idling and the other is for acceleration? Who knows? Who can point us to this theoretical flow meter?

All of this manual calibration sounds like a whole lot of work to me. The ease of just plug and go of the scan gauge to the 96+ vehicles is more my style.

To me it seems easier to make a fuel cell like they use for fuel efficiency testing on myth busters. Weigh the cell before you leave, then weigh it after. Calculate your MPG. Test a route driven with different driving styles, compare results. There are only a few situations that I am curious about and this would seam like a good way of testing them. Once you figure out how to drive with the least fuel use on each route, drive accordingly in the future knowing that you are at maximum efficiency.

|

I used a korean polynom developed in 2011 for a 3.3 gasoline car, to develop a more general model to be used by dinosaur cars (like mine) which don't have all the sensors as to measure fuel injected.

Look the spreadsheet I am attaching and give your comment. My car has a VSS signal but don't have an injection fuel volume signal. I plan to make it of tps and rpm using this model. The model has to be callibrated to each particular car. For this you must produce several point (fuel used, rpm, tps) and try to make the model pass exactly through this points. For that, I provided two constants: one zero constant to lift or down the complete model, and one scale constant to lift or down the slope of the model. Plus, you have to record mean fuel consumption to compare to full tank consumption.

Of course this is a simplification, but such a model should be suitable for making relative comparisons, and acceptable for absolute figures.

OldBeaver

__________________

Mercedes 300 D turbo 1993

Last edited by oldbeaver; 05-16-2014 at 02:30 PM..

Reason: Spelling correction

|

|

|

|

|