Quote:

Originally Posted by puddleglum

Does anyone have any links to some good info on reconditioning my motor. Ben, If you read this, I know you went through yours, but I can't seem to find what you did.

|

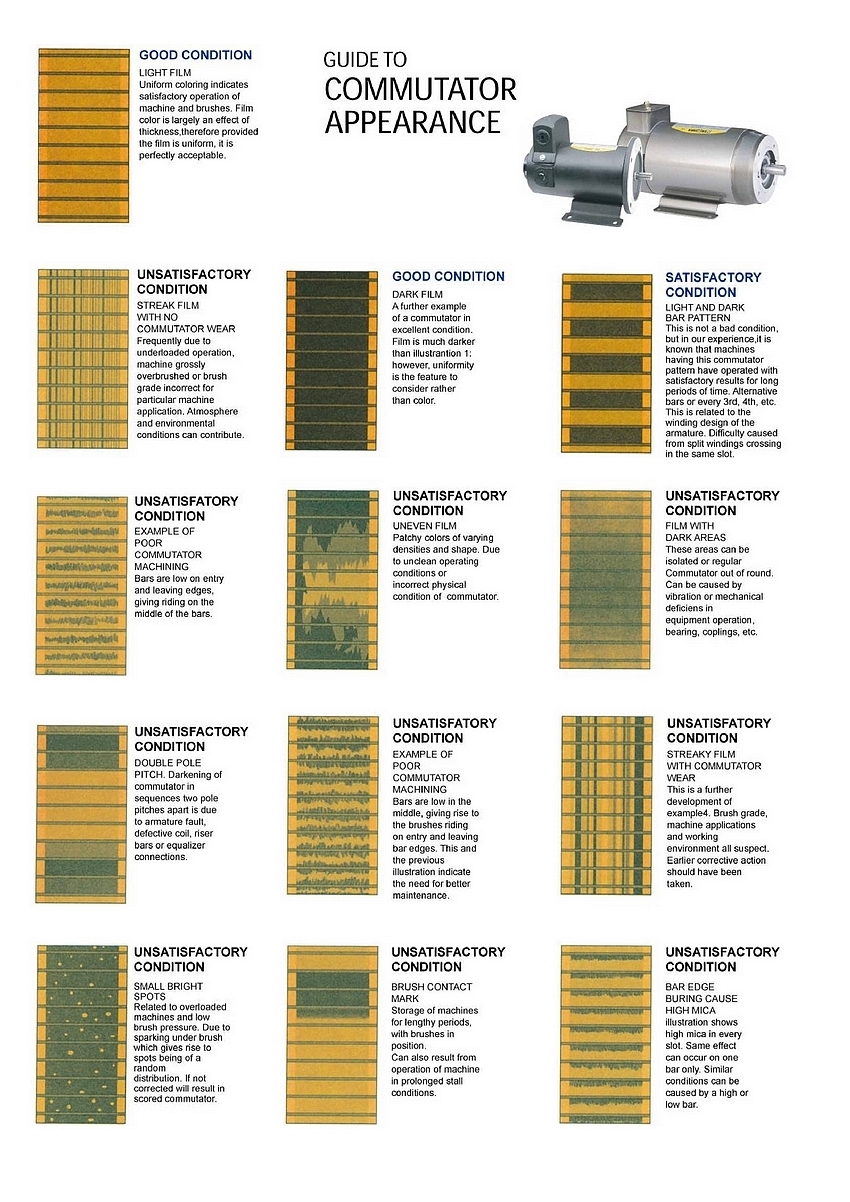

The part of the motor that gets the most wear is the commutator, here is a wear guide that I like.

http://www.gulfelectroquip.com/techn...ame=commutator

I've done a few motors now and my list includes:

Wipe the dirt off.

Replace the bearings if needed.

Replace brushes if needed.

Turn commutator if needed.

If you are going to be pushing the limits of the motor then either replace the brush springs or crank the tension up on them so they press harder.

I have new split brushes from Helwig Carbon, they are harder and should last longer, run cooler and carry more amps.

Helwig carbon recommends champhering the groves in the commutator, not all motor shops will do that, most will just cut the mica down, a champhered edge will arc less allowing the motor to run cooler, ONLY champher the commutator before diamond cutting the commutator or you will make burs that will grind your brushes down to nothing very quickly.

If you replace brushes be sure to wear them in so they are making full contact, this is best done by wrapping the commutator with 220 grit sand paper to get them close then running the motor with no load at near full speed (12v to 24v is common) for a few days, if your brushes don't make full contact they will run hot and could damage them selves or the motor.