04-08-2013, 11:42 AM

04-08-2013, 11:42 AM

|

#11 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Western Wisconsin

Posts: 3,903

Thanks: 867

Thanked 434 Times in 354 Posts

|

Compare the scrap value of some of the parts to the used selling price, a contactor is worth a few bucks in scrap for the copper but might sell for $50 on Ebay, craigslist or to a member of an EV club in your area.

Scrap value on most of the steel parts is around 10 cents per pound so if you can sell a hydraulic pump for 20 cents per pound you are coming out ahead.

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

04-23-2013, 10:59 PM

04-23-2013, 10:59 PM

|

#12 (permalink)

|

|

Master EcoModder

Join Date: Oct 2009

Location: Red Deer, AB

Posts: 421

Thanks: 39

Thanked 96 Times in 69 Posts

|

Well I am officially the proud owner of a dead forklift

Actually it still moves right now but I don't get the battery. Now I just have to find time to tear it apart. With any luck, I will break even once I sell off what I don't need, and have a free motor. The brushes and comm look really good, from what I can see, so hopefully it won't take much to freshen up the motor.

__________________

Almost all my driving is done 1-5 miles at a time.

Best short trip: 2.4 l/100 km, 3.9 km

|

|

|

|

|

The Following User Says Thank You to puddleglum For This Useful Post:

|

|

05-25-2013, 09:59 PM

05-25-2013, 09:59 PM

|

#13 (permalink)

|

|

Master EcoModder

Join Date: Oct 2009

Location: Red Deer, AB

Posts: 421

Thanks: 39

Thanked 96 Times in 69 Posts

|

__________________

Almost all my driving is done 1-5 miles at a time.

Best short trip: 2.4 l/100 km, 3.9 km

|

|

|

|

05-25-2013, 11:29 PM

05-25-2013, 11:29 PM

|

#14 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

Hang onto that drum brake!

I'll tell you why later. It's one of my little EV secrets I learned the hard way!

|

|

|

|

|

The Following User Says Thank You to bennelson For This Useful Post:

|

|

05-25-2013, 11:38 PM

05-25-2013, 11:38 PM

|

#15 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Western Wisconsin

Posts: 3,903

Thanks: 867

Thanked 434 Times in 354 Posts

|

Quote:

Originally Posted by bennelson

Hang onto that drum brake!

I'll tell you why later. It's one of my little EV secrets I learned the hard way!

|

parking brake? |

|

|

|

05-26-2013, 01:37 AM

05-26-2013, 01:37 AM

|

#16 (permalink)

|

|

Master EcoModder

Join Date: Oct 2009

Location: Red Deer, AB

Posts: 421

Thanks: 39

Thanked 96 Times in 69 Posts

|

Thanks, I will. I've been told the brake hub will fit the drive shaft splines and can be used to make a coupler. I plan on saving anything that might possibly be of use or be saleable.

__________________

Almost all my driving is done 1-5 miles at a time.

Best short trip: 2.4 l/100 km, 3.9 km

|

|

|

|

05-26-2013, 10:41 AM

05-26-2013, 10:41 AM

|

#17 (permalink)

|

|

EV test pilot

Join Date: Jan 2008

Location: Oconomowoc, WI, USA

Posts: 4,435

Thanks: 17

Thanked 663 Times in 388 Posts

|

Many forklift motors have a tail-shaft which goes to a brake drum. Because the drive-shaft goes directly to the differential, locking that brake parks the forklift.

On some motors, the driveshaft and tailshaft are the same diameter and spline count (but on some they aren't!  )

You can remove the drum brake, get down to just the splined center, and move it over to the DRIVESHAFT end. It can then become the basis of a coupler to the transmission shaft or flywheel or flywheel replacement.

Beats trying to dig up the right size splined connection somewhere else!

PS - On small front-wheel drive cars, your motor limiting factor is the diameter of the motor (distance from center of transmission to half shaft on the motor side) and the length of the back of the motor to the wheel/tire.

On my electric Geo Metro, the 10.5" diameter just cleared the half-shaft, but the tailshaft was too long. It would have popped the right tire on a left-hand turn if I left the tailshaft on. With it removed, everything was great.

Your motor looks good. Sounds like you are off to a great start! |

|

|

|

06-01-2013, 07:10 PM

06-01-2013, 07:10 PM

|

#18 (permalink)

|

|

Master EcoModder

Join Date: Oct 2009

Location: Red Deer, AB

Posts: 421

Thanks: 39

Thanked 96 Times in 69 Posts

|

Does anyone have any links to some good info on reconditioning my motor. Ben, If you read this, I know you went through yours, but I can't seem to find what you did.

__________________

Almost all my driving is done 1-5 miles at a time.

Best short trip: 2.4 l/100 km, 3.9 km

|

|

|

|

06-01-2013, 09:53 PM

06-01-2013, 09:53 PM

|

#19 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Western Wisconsin

Posts: 3,903

Thanks: 867

Thanked 434 Times in 354 Posts

|

Quote:

Originally Posted by puddleglum

Does anyone have any links to some good info on reconditioning my motor. Ben, If you read this, I know you went through yours, but I can't seem to find what you did.

|

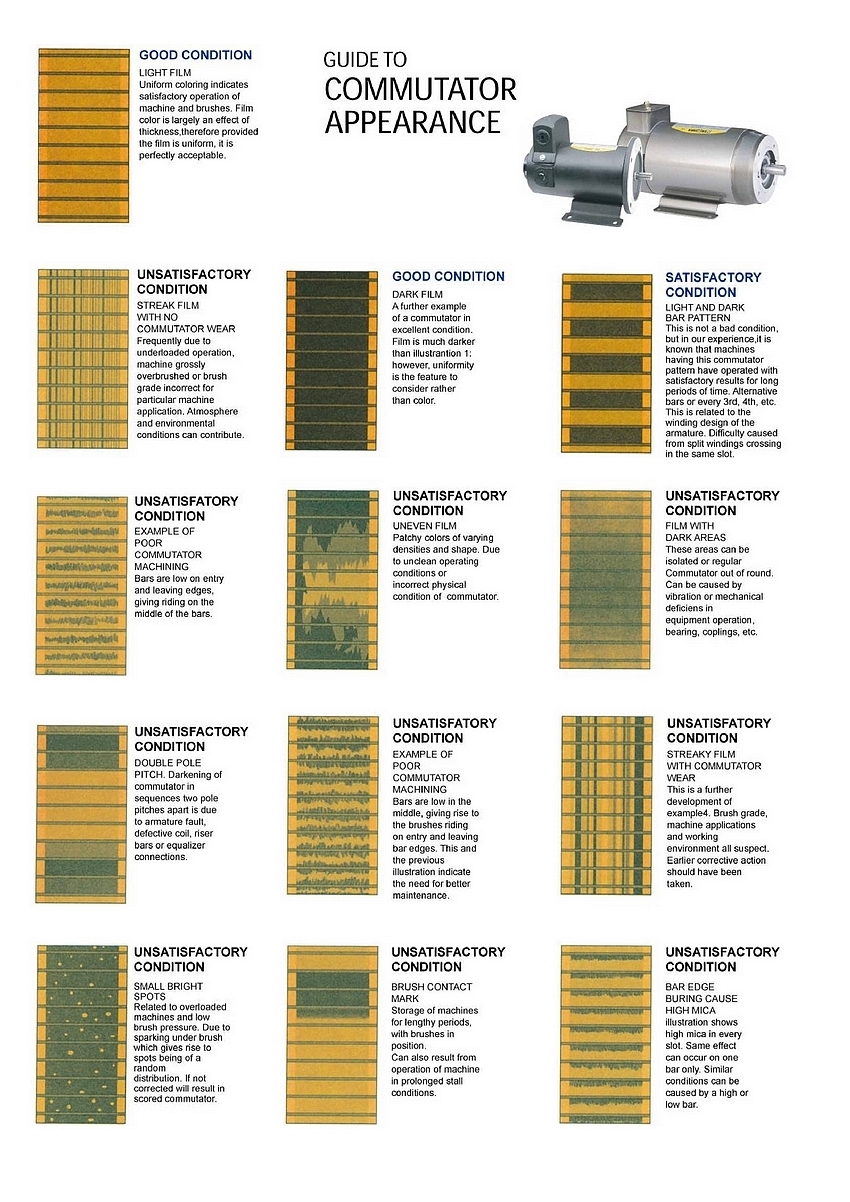

The part of the motor that gets the most wear is the commutator, here is a wear guide that I like.

http://www.gulfelectroquip.com/techn...ame=commutator

I've done a few motors now and my list includes:

Wipe the dirt off.

Replace the bearings if needed.

Replace brushes if needed.

Turn commutator if needed.

If you are going to be pushing the limits of the motor then either replace the brush springs or crank the tension up on them so they press harder.

I have new split brushes from Helwig Carbon, they are harder and should last longer, run cooler and carry more amps.

Helwig carbon recommends champhering the groves in the commutator, not all motor shops will do that, most will just cut the mica down, a champhered edge will arc less allowing the motor to run cooler, ONLY champher the commutator before diamond cutting the commutator or you will make burs that will grind your brushes down to nothing very quickly.

If you replace brushes be sure to wear them in so they are making full contact, this is best done by wrapping the commutator with 220 grit sand paper to get them close then running the motor with no load at near full speed (12v to 24v is common) for a few days, if your brushes don't make full contact they will run hot and could damage them selves or the motor.

|

|

|

|

|

The Following User Says Thank You to Ryland For This Useful Post:

|

|

06-02-2013, 02:55 AM

06-02-2013, 02:55 AM

|

#20 (permalink)

|

|

Master EcoModder

Join Date: Oct 2009

Location: Red Deer, AB

Posts: 421

Thanks: 39

Thanked 96 Times in 69 Posts

|

Thanks Ryland,

the comm condition charts are a great reference.

Those are the things I've done before too on motors we've rebuilt in the shop. I guess what I'm really wondering about is the additional things, if any, that I should be doing before tripling the rated voltage of the motor for EV use. I think Ben pulled the field coils right out of his and wrapped them in special tape. I've seen some guys adding extra banding and varnish to the armature and field coils. Are all those things necessary or precautionary? I know I will need to advance the timing if I go to 144 volts, but not sure what the voltage limit is before I have to advance it.

__________________

Almost all my driving is done 1-5 miles at a time.

Best short trip: 2.4 l/100 km, 3.9 km

|

|

|

|

|