You're right of course Jim, though the one saving grace is that I unscrewed two of the rods so that they rolled freely - which is the proper way to do it if I understand correctly? The only other reason is that the way I did it, the screws in the long leaf of the hinge are not under stress. If it was on the bottom edge, then they would be put under tension.

The hinge is located to let the 2x6 be (very close to) level so the motion is close to straight down.

After thinking about my above question, I think it is really simple: I just have to divide the shorter radius by the longer one (which results in a ratio less than 1:1) and then multiply that by the arc length I measured. This should result in the actual deflection of the sample?

The rest of the formula cancels out, I think.

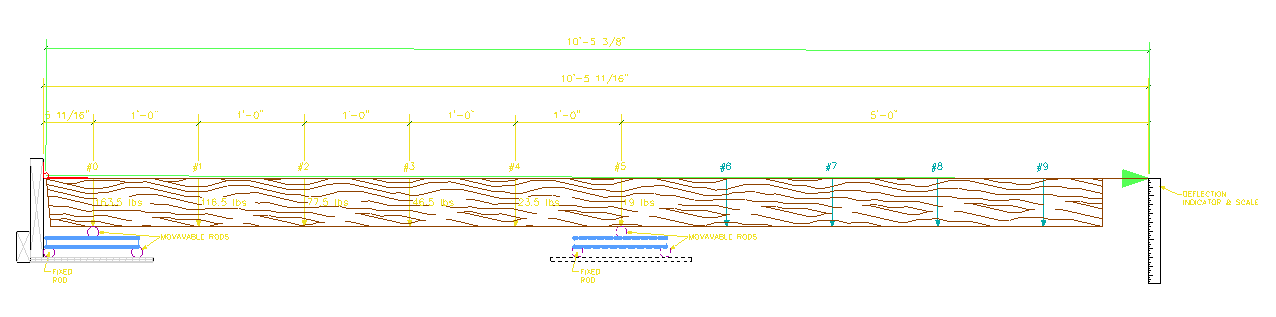

Here's the drawing of the testing jig:

I used Position #5 first, then #4, #3, #2, and #1 last. Position #0 resulted in over 7" (measured at the end of the arm!) deflection, effectively bottoming out the jig.