My test only shows relative strengths of the fiberglass fabrics. The only way to test the structure is to test the chassis I'm building. After I start the fiberglass on the chassis, I'll be able to test the actual thing, by loading it; not unlike how Burt Rutan tests his composite airplanes.

Folks, I weigh ~235 pounds and with the plywood (which weighs about 40 pounds?) inside the chassis - with on the foam only, and it was fine. So, the giant 'U' shape forms a strong structure, and when it gets the fiberglass it will be a lot stronger.

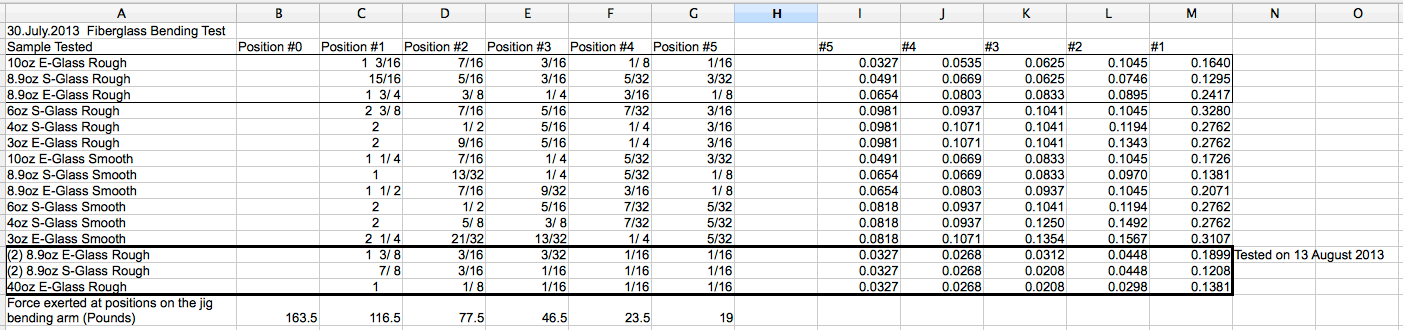

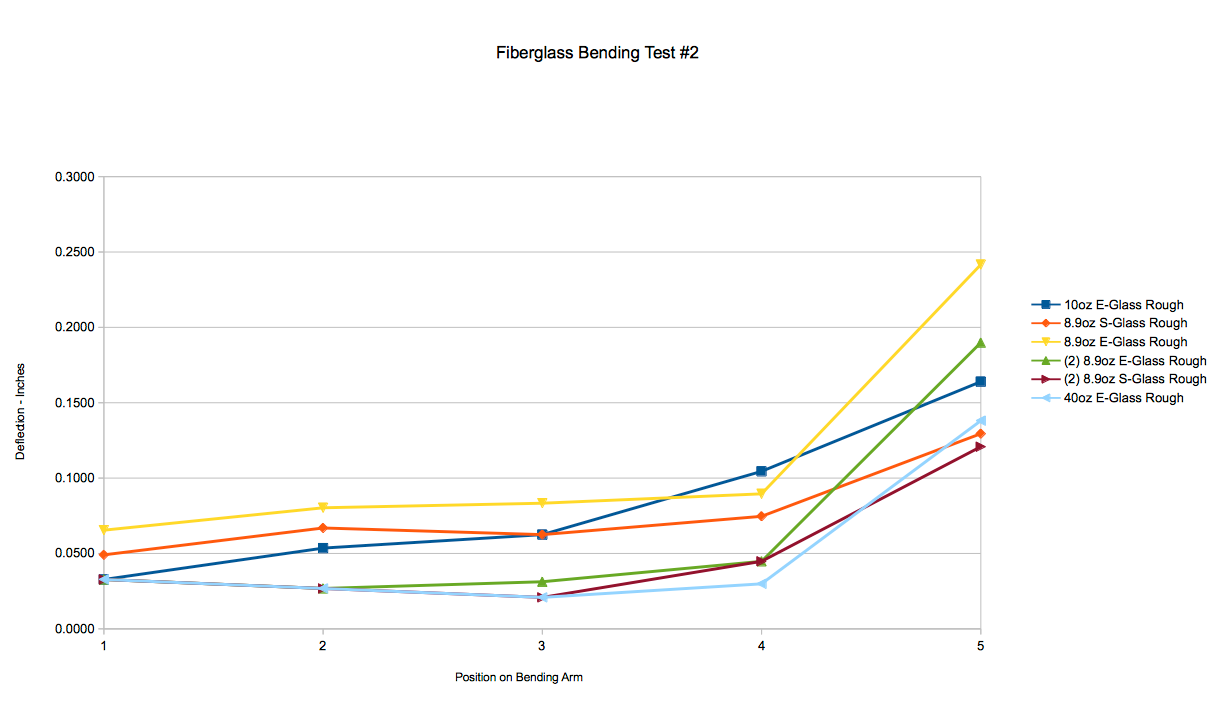

Edit: I've now rested the 3 new samples and charted them in comparison to the 3 strongest samples from the first test.

The deflection is less on the newer samples, but the 'knee' is at the same load, and the top of the two layers samples is wrinkling, indicating (I think) that the thickness of the sample (1") and/or the compression strength of the foam is the limiting factor. Also, notice that the deflection at the lower weights is below the "resolution" of my jig.

Edit 2: here are pictures of the new samples: