08-10-2013, 04:25 PM

08-10-2013, 04:25 PM

|

#491 (permalink)

|

|

EcoModding Lurker

Join Date: Apr 2010

Location: Florida

Posts: 78

Thanks: 0

Thanked 17 Times in 11 Posts

|

Neil,

I work in the aviation industry and work with composites on a regular basis. When it comes down to it, I end up using West System w/slow hardener as my "go to" repair epoxy. It is easy to work with, reliable, trouble free and produces a quality part or repair. Even by hand, without vacuum bagging.

You could easily go crazy and choose super expensive Hysol products, and not get better results.

Interestingly, a simple "2 core 2" panel of carbon fiber and West Sys (2 layers carbon each side of the core) uses very little epoxy and is amazingly strong. Good enough for high end aerobatic aircraft that regularly see 10G's.

|

|

|

|

|

The Following 2 Users Say Thank You to cujet For This Useful Post:

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

08-10-2013, 11:20 PM

08-10-2013, 11:20 PM

|

#492 (permalink)

|

|

Not banned yet

Join Date: May 2010

Location: Texas Coast, close to Houston

Posts: 907

Blue - '03 Chevy S-10, LS

Thanks: 423

Thanked 266 Times in 213 Posts

|

__________________

2003 S-10, 2.2L, 5 speed, ext cab long bed.

So far: DRL delete, remove bed mount toolbox.

Last edited by deejaaa; 08-11-2013 at 01:30 PM..

|

|

|

|

08-11-2013, 07:30 AM

08-11-2013, 07:30 AM

|

#493 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

I gotta build it to be able to test it.

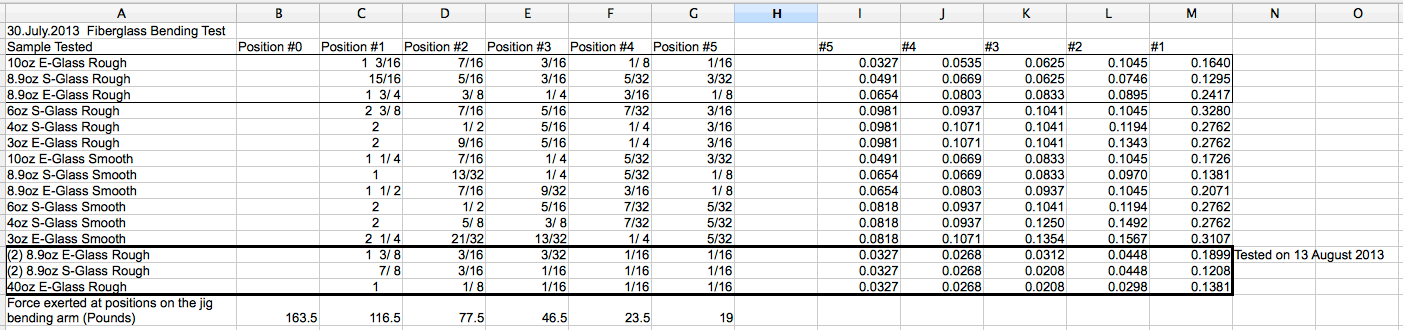

I'm back from vacation, and I've made three more samples:

(2) layers 8.9oz E-glass each side with rough surfaces

(2) layers 8.9oz S-glass each side with rough surfaces

40oz E-glass each side with rough surfaces

I try to test them tomorrow to allow a similar dry time to the previous samples. |

|

|

|

|

The Following User Says Thank You to NeilBlanchard For This Useful Post:

|

|

08-11-2013, 08:52 AM

08-11-2013, 08:52 AM

|

#494 (permalink)

|

|

EcoModding Lurker

Join Date: Apr 2010

Location: Florida

Posts: 78

Thanks: 0

Thanked 17 Times in 11 Posts

|

Neil, I'm not at all being critical. Sorry if I came off that way. Your project is extremely interesting to me.

What I had intended to say was that "2 core 2" , done properly is exceptionally economical with epoxy use. In other words, one quart of the stuff will go a very long way. It's not at all like fiberglass construction in the old days.

|

|

|

|

|

The Following User Says Thank You to cujet For This Useful Post:

|

|

08-12-2013, 11:26 PM

08-12-2013, 11:26 PM

|

#495 (permalink)

|

|

It's all about Diesel

Join Date: Oct 2012

Location: Porto Alegre, Rio Grande do Sul, Brazil

Posts: 13,042

Thanks: 0

Thanked 1,720 Times in 1,534 Posts

|

Quote:

Originally Posted by Christ

This one's a prototype, right?

Prototype vehicles are NEVER built with top-end materials.

|

Sure, but there's a difference between not choosing top-end materials and a suicidal attempt. |

|

|

|

|

The Following User Says Thank You to cRiPpLe_rOoStEr For This Useful Post:

|

|

08-13-2013, 01:53 AM

08-13-2013, 01:53 AM

|

#496 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,433

Thanks: 8,375

Thanked 9,129 Times in 7,538 Posts

|

I'm with [cut]cRiPpLe_rOoStEr[paste].

My concern is that you are testing with thin rectangular strips and will extrapolate to the gross structure.

Your results might be affected by edges or corners. I'd test by using a circular clamp aka two pieces of pipe; and drop a ball in the center. To isolate the behavior of the material en mass. At that particular thickness. In other words you would be able to test the performance of thickened edges and flanges as well as a thin skin.

|

|

|

|

08-13-2013, 09:12 AM

08-13-2013, 09:12 AM

|

#497 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

My test only shows relative strengths of the fiberglass fabrics. The only way to test the structure is to test the chassis I'm building. After I start the fiberglass on the chassis, I'll be able to test the actual thing, by loading it; not unlike how Burt Rutan tests his composite airplanes.

Folks, I weigh ~235 pounds and with the plywood (which weighs about 40 pounds?) inside the chassis - with on the foam only, and it was fine. So, the giant 'U' shape forms a strong structure, and when it gets the fiberglass it will be a lot stronger.

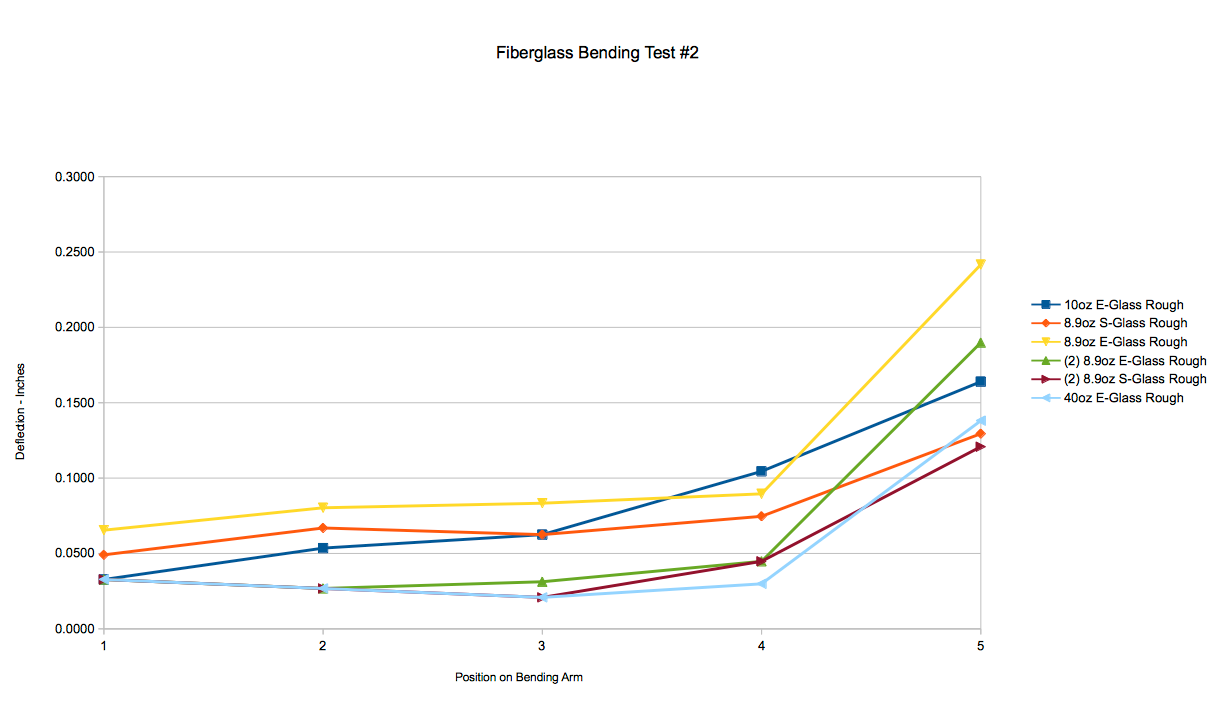

Edit: I've now rested the 3 new samples and charted them in comparison to the 3 strongest samples from the first test.

The deflection is less on the newer samples, but the 'knee' is at the same load, and the top of the two layers samples is wrinkling, indicating (I think) that the thickness of the sample (1") and/or the compression strength of the foam is the limiting factor. Also, notice that the deflection at the lower weights is below the "resolution" of my jig.

Edit 2: here are pictures of the new samples:

Last edited by NeilBlanchard; 08-13-2013 at 11:10 AM..

|

|

|

|

08-13-2013, 03:33 PM

08-13-2013, 03:33 PM

|

#498 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,433

Thanks: 8,375

Thanked 9,129 Times in 7,538 Posts

|

OK, I went back and looked. They were always that size weren't they? ...I confuse easily.

How's it going with the windshield?

|

|

|

|

08-13-2013, 06:16 PM

08-13-2013, 06:16 PM

|

#499 (permalink)

|

|

Master EcoModder

Join Date: May 2008

Location: Maynard, MA Eaarth

Posts: 7,908

Thanks: 3,475

Thanked 2,953 Times in 1,846 Posts

|

Yes, all the samples have been the same size - about 10 1/2" x 6" x 1". The test span is 10" with the bearing rod 5" from either support. Two of the three rods are free-moving and one is fixed.

I still need to buy the windshield and the wipers to go with it.

Edit: The box beams in the frame of a 1/2 ton pickup are about 6" deep. The floor of CarBEN is about 8-9" deep, and the sides form a 'U' that is about 32-36" deep. The box beam on the pickup is about 2" wide, and the bottom of CarBEN is about 5 *feet* wide.

Last edited by NeilBlanchard; 08-13-2013 at 10:13 PM..

|

|

|

|

|

The Following User Says Thank You to NeilBlanchard For This Useful Post:

|

|

08-14-2013, 10:13 AM

08-14-2013, 10:13 AM

|

#500 (permalink)

|

|

EcoModding Lurker

Join Date: Jul 2013

Location: Guadalajara, Mexico

Posts: 13

Thanks: 4

Thanked 2 Times in 2 Posts

|

Neil,

I ran across this information recently about windshields. I can't post a link but if you go to Facebook and search for Wikispeed and select the top item of the search it shows how these people assured a good fit for their windshield.

Stan

|

|

|

|

|

The Following User Says Thank You to stankoprowski For This Useful Post:

|

|

|