Part of the plan here is to get the tachometer working. Although I don't REALLY need it, it would be cool to have. Currently the only gauge that works is my speedometer, which is lame.

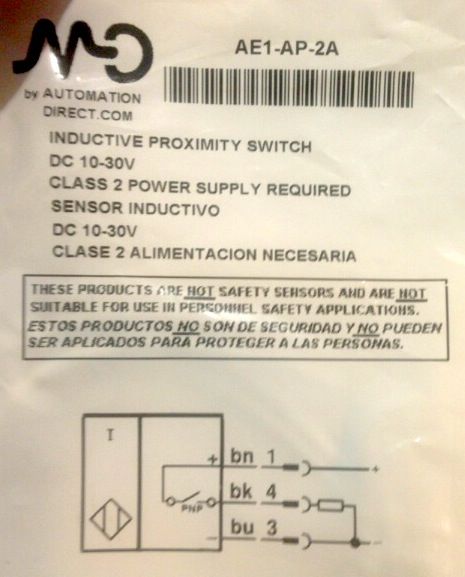

Today I had a breakthrough. My friend Matt (the machinist) gave me a proximity sensor, which is basically a switch that turns on when metal is nearby.

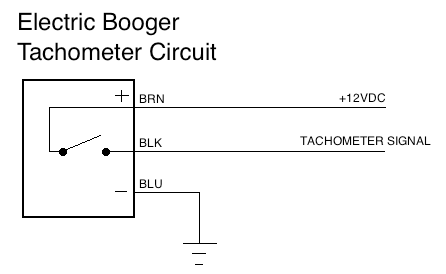

My tachometer was originally fed a signal from the negative side of the ignition coil (which is the norm). I wired the proximity sensor this way to achieve a similar signal:

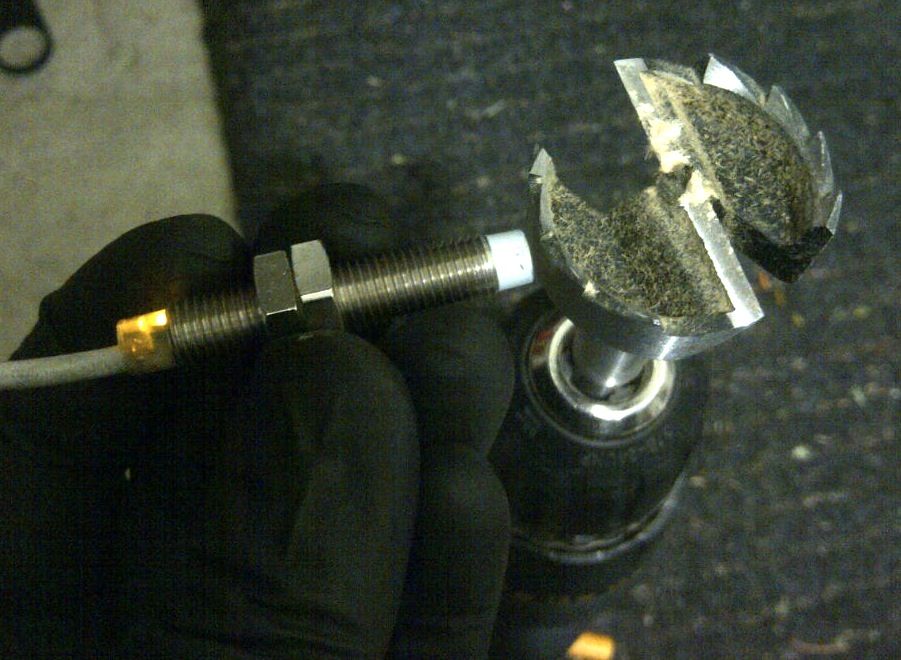

Since this was a four cylinder, with four engine position teeth in the distributor turning at half engine speed, I planned to put two pickup teeth on my drive coupler. Here is my wild setup to test it out:

A cordless drill with a hole cutting bit with two cutouts. In theory, my tach should accurately tell me the speed of my drill. So with a fully charged battery in the drill I let 'er rip. The drill says 0-1300 RPM on it, and my tach showed 1200 RPM.

CLOSE ENOUGH!