Alrighty then - more guts, more glory!

Here is the gearbox side of the system; this is where I figured some improvement could be added.

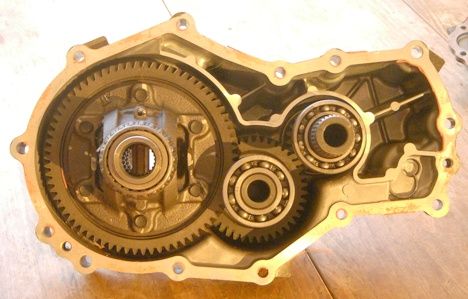

Here is the gearbox side of the center (stator, etc) section. Not really much to see here, except note that there are pockets for bearings on every shaft, and that there is very little extra room.

Also, there is a potential for an oil fill or cooling oil port directly above the output shaft. You can see the plug bolt in the "top" view next to the breither port (above the power connector in this view) The next views that show the other side of the gearbox will show the oil flow better.

Here is a shot of the gearbox side of the MGR, with the geartrain loosely fit in. In this shot the "oil pump" made by the differential's main gear and the gearbox is visible. Oil is deposited into the containers above the geartrain. While this system is very reliable, there are two problems. 1) You cannot run this motor for any extended time in reverse. It will not get any oil. 2) Oil is used for both lubrication and distributing the heat load. The case and the fins on the case are the only method for getting rid of heat. While this might work ok for standard gearboxes, in this case there is a significant additional load - the motor! To ensure the system reliability, Toyota built into the control a thermal limit measured by sensors in the stator. By doing a better job of cooling the oil, it will be possible to cool the stator more effectively, and thus push the motor harder.

The gear on the right is the output of the motor, with a splined connection to the rotor. Both the motor rotor and this shaft each have a set of ball bearings on the shaft ends. I think it is made this way so balancing the rotor for 10,500rpm is easier.

This is the gearbox side without the gears in place. Note the oil passages and specifically the one for the motor. There is a special passage made to deliver oil through the center of the hollow shaft.

The outside of that part. The bearing pockets and oil passages are all easily visible. They didn't spare a bit of metal in making this part! Also note that there is an oil port right where oil is put into the motor's hollow shaft. It may help to add cooled oil directly here.

The gearset. Freebeard's suggestions for polishing and hardening the gears would be a good help. Also, My EVIL plan is to use one of these motors for every wheel. I will need to lock the differentials to do this. Does anyone have ideas for a company that makes custom spools or something like that?