|

different way of looking at it

so

first off

i see some of the systems in images here in this thread are tightly woven

messes

flow in them is going to be UN consistent at best

and that is exactly what is NOT wanted

dynos are useless for measuring flow

imho

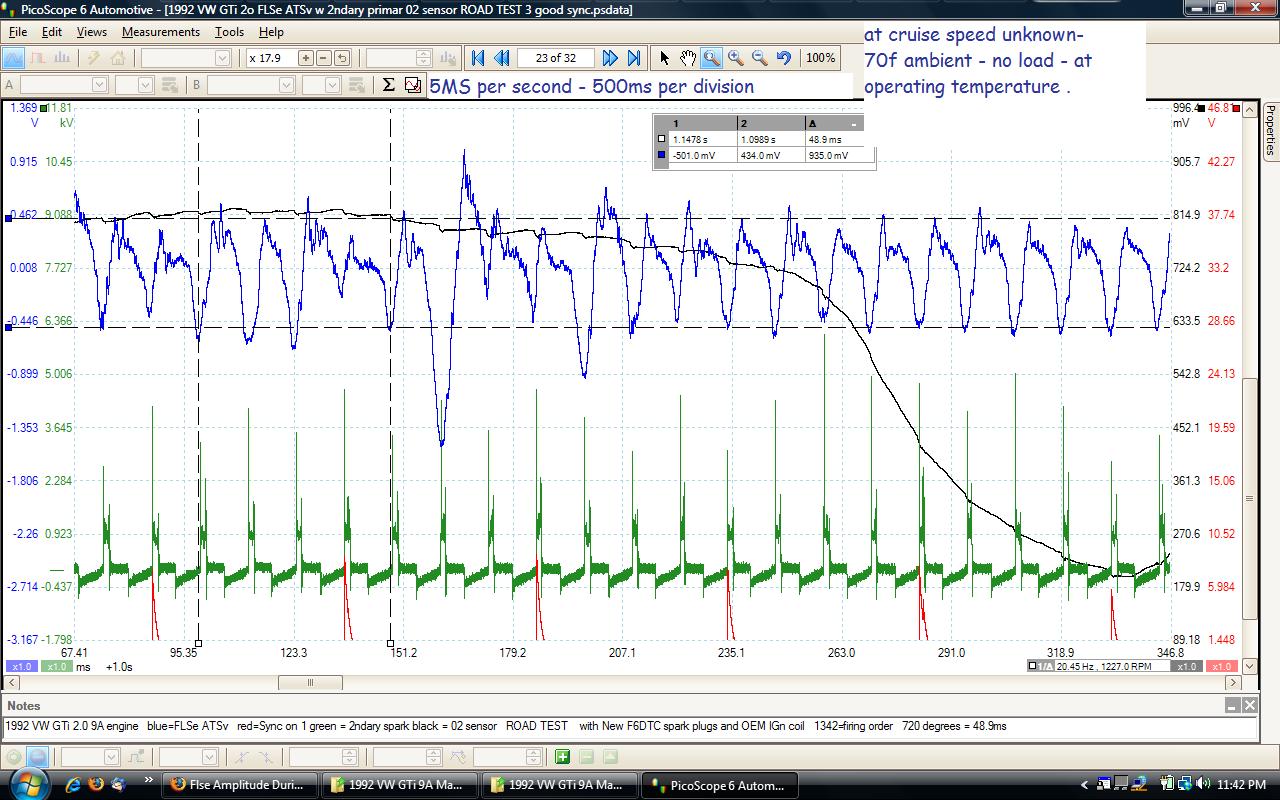

this simple waveform capture shows exhaust pressure per cylinder (green) with intake pressure (red) with secondary spark which roughly shows about 10 degrees before TDC of each cylinder

note

how UN even and erratic the green exhaust pressure / flow is

on a stock G10 Geo Metro with the engine not running , just operating the starter , that is because of the way the exhaust manifold is configured .

at higher rpm under load

exhaust flow is

tragic

but

it will be no WORSE than what the "alleged " header systems depicted will show

compare to this

there is a long line misfire to the left of center but

excepting that

look at the blue trace , note how uniform each exhaust pulse is

at cruise around 40 to 45 mph

that is what is desired a uniform pulse train

you will never achieve a uniform pulse train with a knotted pretzel shaped exhaust

you will never see this using a dyno or hypothetical software

does this matter

yes it does

turbulence is never your friend when you are attempting to improve VE

and that is your goal to IMPROVE VE

you can not improve VE by reducing VE .

Last edited by mwebb; 11-22-2014 at 11:28 PM..

Reason: image was broken

|