Sorry it doesn't seem like much has been happening with this.

I've been working on the design for a spool and one sided output so I can use this for a 1 motor/wheel type setup.

The drivetrain shop I'm working with is willing to take this on.

So after a few meetings and a few design iterations, we're finally getting to a "make-able" design.

One of the toughies is dealing with splines, and for a number of reasons, I'm going with a splined design rather than other options. The main problem is the internal spline - broaches are extremely expensive. Fortunately, the shop I'm working with has two that are nearly perfect for this part!

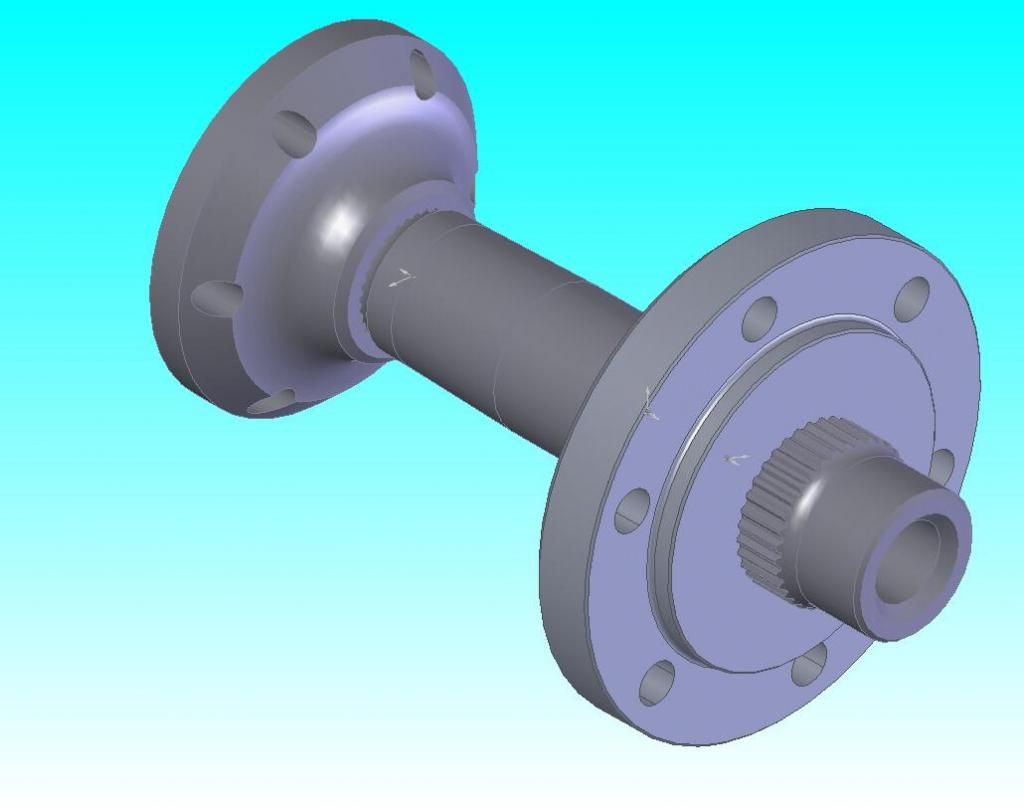

Here is a pic of the spool design; it still needs a bit of work:

I've done some FEA analysis, and it looks like there are no high stress areas that will result in fatigue failure, etc. The axle is made of 4340 steel and the flanges are made of something weaker, like 4140. Surprisingly, the ring gear flange could be made of 2024-T4 aluminum. The flange on the left is designed to accept a 100mm "Type 2" VW CVT. The right flange is designed to bolt directly to the MGR's ring gear. This part would elliminate the differential carrier, using the tapered roller bearings that the differential carrier currently uses.

- E*clipse