Tip from me:

If you're printing with ABS which I assume you are.

You know how the surface finish shows the layers and sucks? Buy some acetone and a glass jar. Put some acetone in the jar, suspend your part in the jar. But the lid on. The acetone vapors will melt the outer layer of plastic. Take the part out. Let it sit for a day. Come back and you'll have parts that look like molded plastic bits. You'll have to play with time and distance from the acetone at the bottom of the jar but I find about 10 minutes to be good. Make sure to do this under a fume hood or outside. It takes practice to get this right.

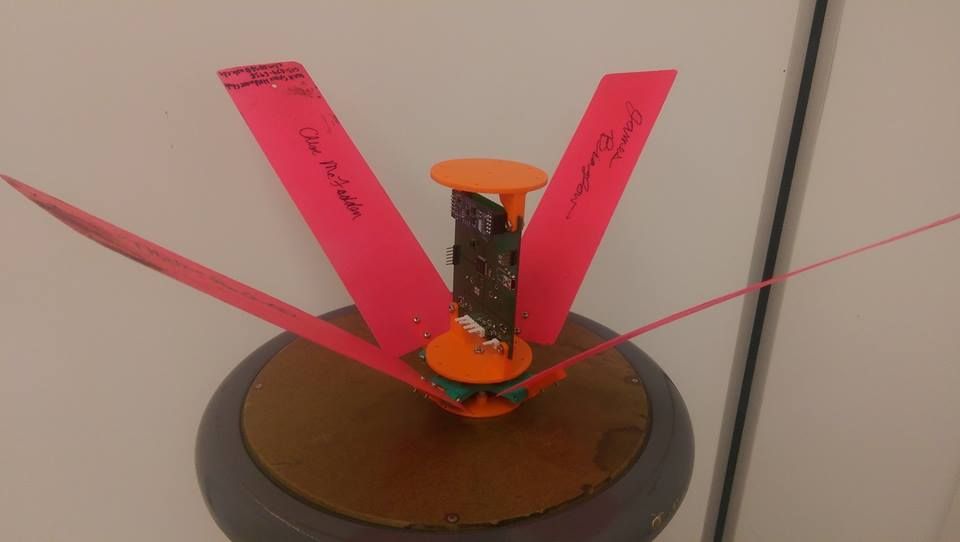

The picture is the science vehicle that my team and I designed for an international collegiate design competition that we're going to this June. Aside from the fiberglass blades, every other piece is made with printed ABS. This science vehicle withstood 26 G's and a 2 gram black power deployment charge during a rocket flight.

Anyway, 3D printing is awesome! Aside from CNC and watercutting, it's probably my favorite manufacturing technique.