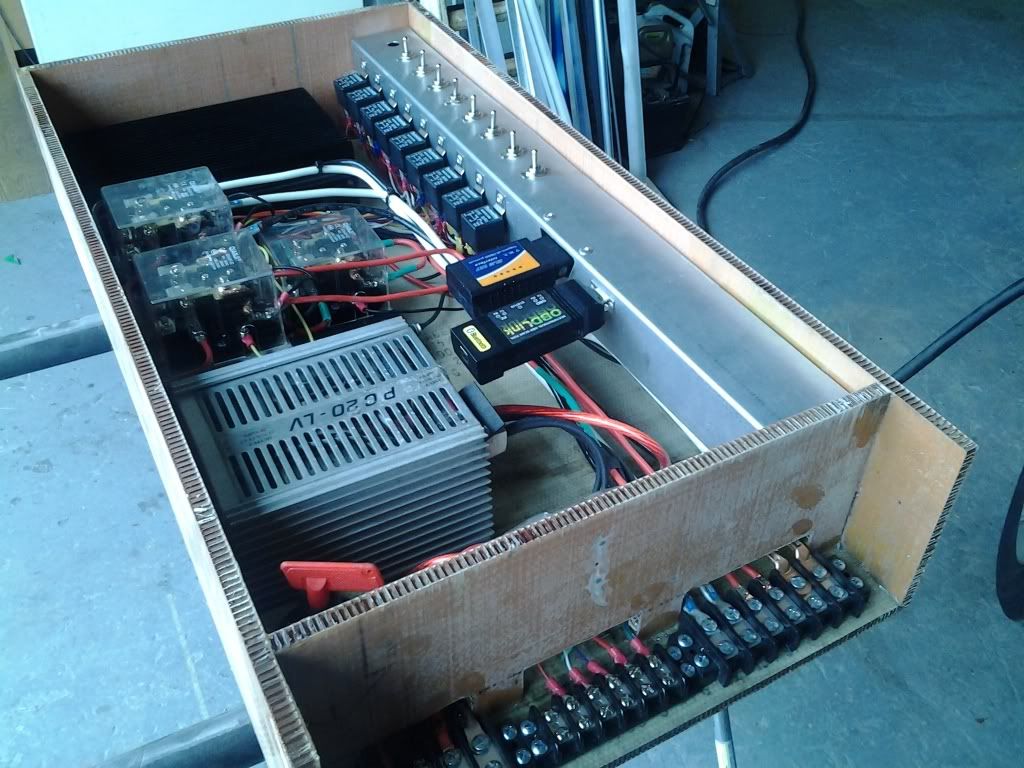

I had a pretty good sized scrap of honeycomb fiberglass laying around, so I chopped it up and made this electronics enclosure with it. This will all be hidden, so I am not going to make this thing pretty. The fiberglass honeycomb is extremely light, but very strong material. When this box is empty, it feels like an empty cardboard box. Anyway, I have some contactors in this box, an Orion BMS, and an old skool DC DC converter that I had leftover from another conversion, all of my configuration switches and relays, and my wifi and Bluetooth signal transmitters in this box. The wire junction strips on the end make it easy to connect this module to the car, since I have all kinds of relay logic going on in here.

Those two contactors that are side by side in the above pic are for my charging cord inlets. Since the charger does not care if it gets 110 or 220, both of the charging inlets can be wired in parallel. The problem with this, is that the pins on the car need to be male, so if you were plugged into 220, the 110 male pins for the 110 extension cord would be live and dangerous. Those two contactors and some of those little cube relays are used to isolate the two charging inlets from each other. I also set it up so that you can plug in your regular 110 extension cord, and then forget that you already plugged it in, and then plug in the 220 cord as well. The 220 inlet will dominate, and the 110 will not go anywhere if you make this dumb mistake.

This is the 110 charging inlet that I use. Although this is the slowest way to charge an EV, 110 plugs are EVERYWHERE in North America. If you ever get yourself in trouble and need a charge, 110 is your friend. I don't use the 110 very much, but I think it is foolish to own an EV in North America and not have one of these on your car.

These can be mounted with the threaded nut that is on these threads, or with screws on the front side.

I modified a part for a home electric panel to accept my inlet, and mounted it solidly to the car.

and then chopped a hole in my filler panel between my tail lights. The filler panel is not strong enough to take the abuse of repeated plugging in and unplugging, which is why the inlet is mounted solidly to the car. The filler panel is pure decoration.

Here is that panel all repainted with metallic black from a 2012 Dodge Charger

Now the car is restored, ready for tail lights and the filler panel

Here it is all built. Tail lights polished and loaded with LEDs, and a very functional and good looking 110 inlet. The slowest and surest way to charge an EV. The automakers are still trying to sell new EVs with a big ass cord with a funky heavy box in order to use 110v. I think it is called an EVSE?

This is what I use for 220. This is a 50 amp connection, so this is what I like to use the most. I can draw all 50 amps and then some from the wall, and I have a big circuit for my welder at the shop with a 25 foot extension cord already, so I am well set up for charging at work.

This is the box that I mount it in. The lid squeezes the cord end into the box so I can ram my charging cord in and out without having to worry about things. Very rugged.

Here it is ready to plug in

Here it is plugged in