06-15-2015, 10:55 PM

06-15-2015, 10:55 PM

|

#417 (permalink)

|

|

Changfa diesel + Suzuki

Join Date: Jul 2012

Location: Northern, NY

Posts: 527

Centurion - '74 FIAT X1/9 Centurion Full Race DNA Last 3: 143.5 mpg (US)

Thanks: 160

Thanked 463 Times in 235 Posts

|

Funyuns and Trunnions!

-

-

-

Many folks have heard of "Funyuns" but not as many have heard of "Trunnions". Triumph (and some other early cars) did use a ball joint in the upper part of their front suspension, but did not use a lower ball joint. Instead, they used something called a trunnion. This trunnion allowed the front suspension to move up and down (over road bumps, etc) while helping the tire tread to stay true to the road surface. It also allowed for the front wheels to steer left and right around its lower pivot point.

-

Like ball joints, trunnions can, and do, wear out. And like ball joints, sometimes they break! When this happens the front wheel usually goes up into the fender and the front of the car slams down to the road  : :

-

-

-

-

-

The trunnions on this Centurion are indeed the originals from 1966! It was time to replace them and as luck would have it, there is a new design that will do away with the trunnions forever! To replace them required removal of the front wheel:

-

-

-

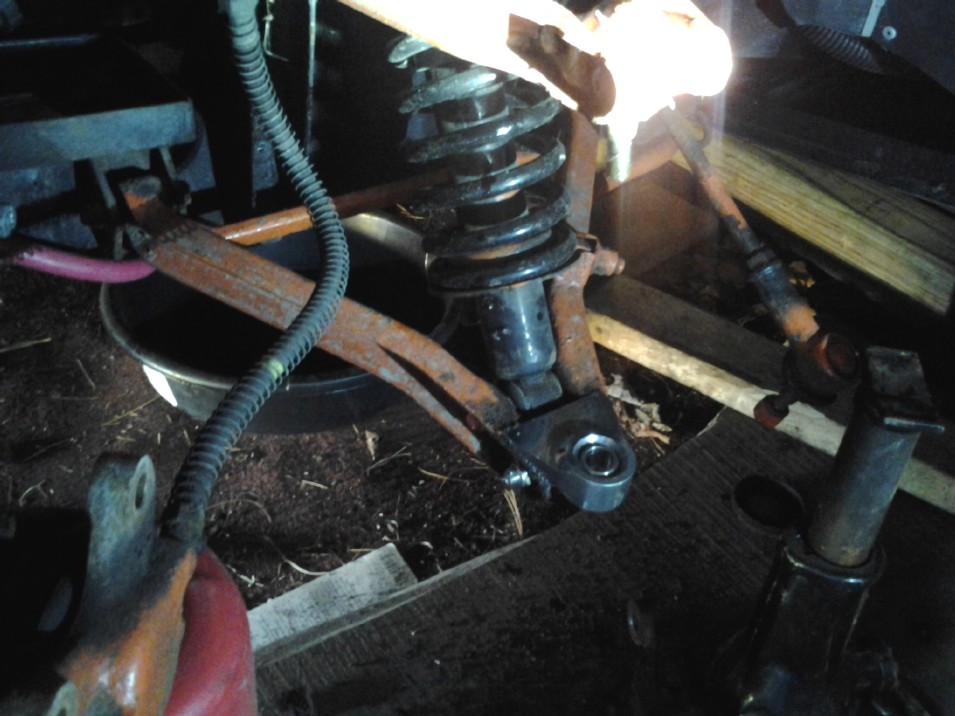

The trunnions (and vertical link they are attached to) can be seen from behind:

-

-

-

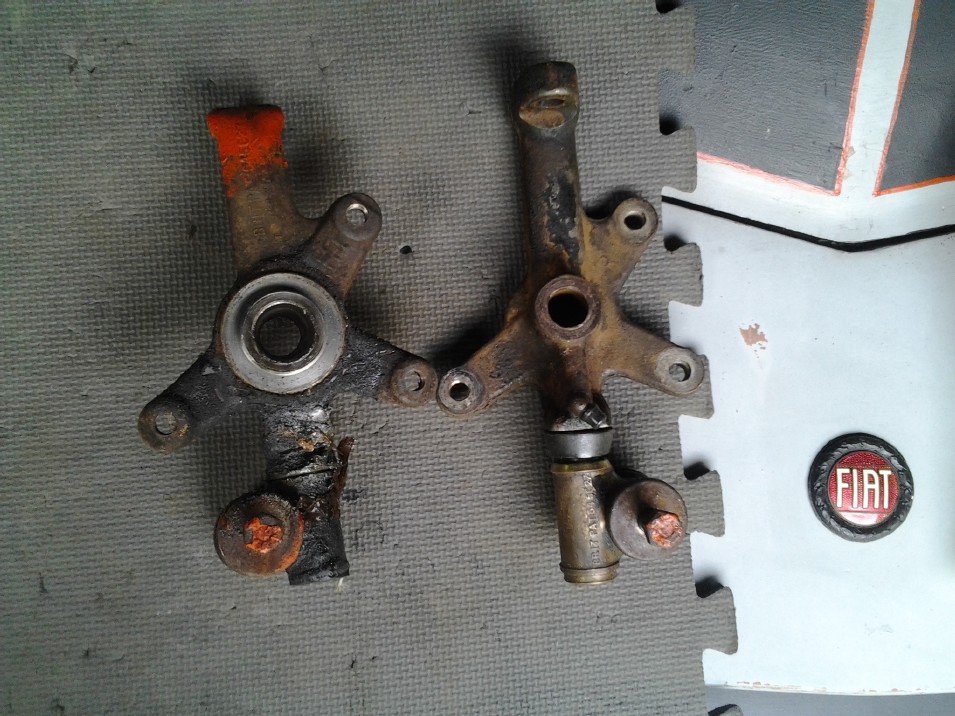

And once removed we can see very clearly, the vertical link and the trunnion:

-

-

To understand why they sometimes fail with no warning, we need to look a bit closer.

-

Notice in the photo below that the brass trunnion on the right threads onto the vertical link:

-

-

-

And if we unscrew the trunnion all the way it will of course be free from the vertical link. As you look at this photo, notice the threaded vertical link is drilled up through the center. This hole is supposed to provide a path for oil to flow downward into the trunnions when it is serviced (lubed). The oil that is down in the trunnions is then supposed to wick up the onto the threads and help keep this assembly from prematurely wearing out. The drilled hole also presents a problem. The material that was removed in the drilling process has also made the part weaker. In addition, all those threads used to hold it together, has also made the part weaker:

-

-

-

It has also been said that rust can form beneath the protective rubber rings that were designed to keep debris from getting in. Looking beneath that rubber ring there is some rust starting.

-

-

-

When the vertical link fails, it will break at the weakest point which may be either at the threaded area or at a bad rust scored area. And this is a photo of a failed vertical link:

-

-

-

-

The new design specifically to eliminate this problem uses a vertical link that is not drilled so it is stronger than the original:

-

-

-

And the trunnion is now replaced by a simple heim joint:

-

-

-

Now that we all up to date with the Trunnions, wouldn't you rather have just dealt with the Funyuns?

-

-

-

~CrazyJerry

Last edited by changzuki; 08-03-2018 at 11:39 PM..

Reason: Hungry for a funyun!

|

|

|

|