Quote:

Originally Posted by freebeard

I'm gathering parts for a 1Kw gravity vortex watermill. I've got a washing machine motor, a housing made from parts (a dog kennel and a ventilator!) and two outboard motor propellers to choose from (3-blade metal and 6-blade plastic). All I need now is a shaft to connect the propeller to the motor/generator and an optional extension tube that necks down from 14" to ~7".

Do you think it would be better to square the tips of the blades and put it in a duct, or leave the tips and put it below the end of the duct?

|

I don't know what I found humorous about your post as I haven't been drinking or anything, just didn't expect it.

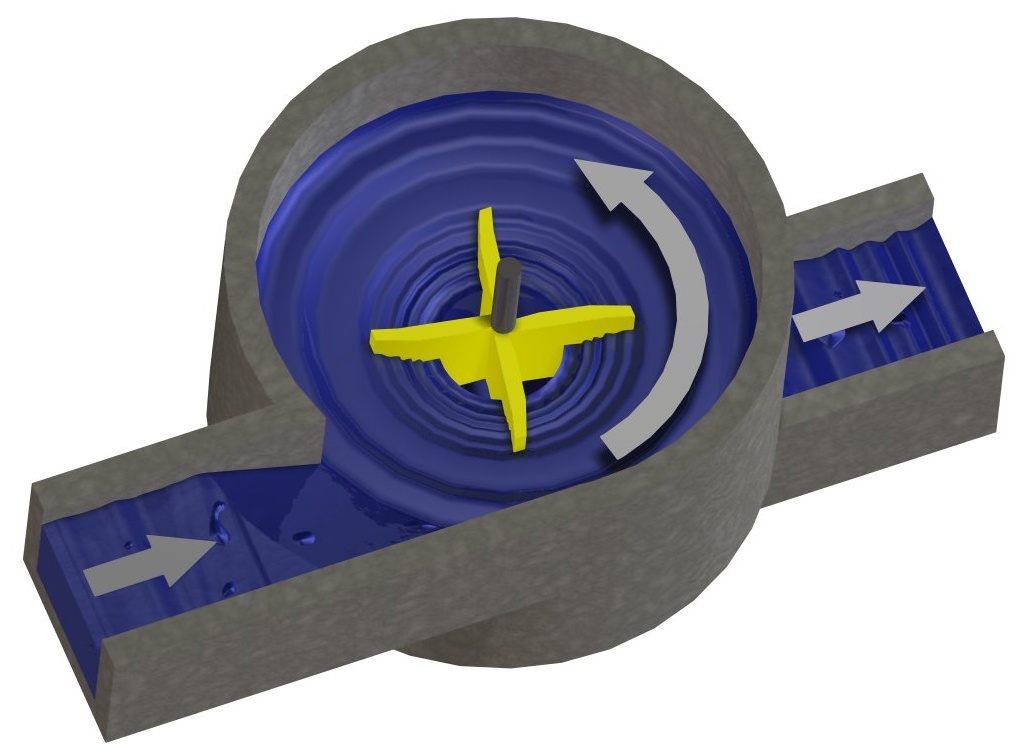

I'm picturing something like the below.

Gravitation water vortex power plant

https://en.wikipedia.org/wiki/Gravit...ex_power_plant

Quote:

The gravitation water vortex power plant is a type of micro hydro vortex turbine system which is capable of converting energy in a moving fluid to rotational energy using a low hydraulic head of 0.7–3 metres (2 ft 4 in–9 ft 10 in). The technology is based on a round basin with a central drain. Above the drain the water forms a stable line vortex which drives a water turbine.

It was first patented by Greek-Australian Lawyer & Inventor Paul Kouris in 1996[1], who was searching for a way to harness the power inherent in a vortex.[dubious – discuss]

Later, Austrian Inventor Franz Zotlöterer created a similar turbine while attempting to find a way to aerate water without an external power source.[2]

|

My guess is that ducted systems are more efficient.

Ducted fan

https://en.wikipedia.org/wiki/Ducted_fan

Quote:

A ducted fan is a propulsion arrangement whereby a mechanical fan, which is a type of propeller, is mounted within a cylindrical shroud or duct. The duct reduces losses in thrust from the tips of the props, and varying the cross-section of the duct allows the designer to advantageously affect the velocity and pressure of the airflow according to Bernoulli's principle. Ducted fan propulsion is used in aircraft, airships, airboats,[dubious – discuss] hovercraft and fan packs.[1]

Ducted fans normally have more and shorter blades than conventional propellers and thus can operate at higher rotational speeds.[dubious – discuss]

|

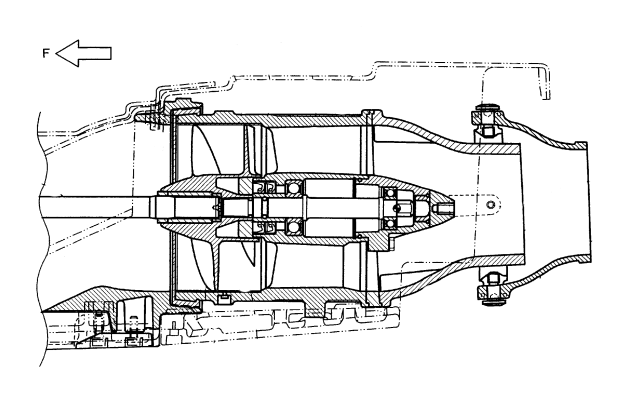

Pump-jet

https://en.wikipedia.org/wiki/Pump-jet

Quote:

|

A pump-jet, hydrojet, or water jet is a marine system that creates a jet of water for propulsion. The mechanical arrangement may be a ducted propeller (axial-flow pump), a centrifugal pump, or a mixed flow pump which is a combination of both centrifugal and axial designs. The design also incorporates an intake to provide water to the pump and a nozzle to direct the flow of water out of the pump.[1]

|

Energy is going to squirt out the ends of the blade tips (right angles?) and will not be contained in the system if there is no containment duct. A bad thing in my opinion.

I'm just making this up as I go along, if anyone has direct experience please chime in. I've only messed with my hovercraft duct before.

EDIT: This looks to be pre-duct, not post duct or in-duct.

http://www.zotloeterer.com/welcome/g...-power-plants/

[IMG]http://www.zotloeterer.com/attachments/Image/GWVPP-OGRA-2014_1.jpg?template=generic[IMG]

Quote:

|

We will support you with consulting and planning and during project realisation.

|