08-24-2018, 06:46 PM

08-24-2018, 06:46 PM

|

#71 (permalink)

|

|

Master EcoModder

Join Date: Jul 2011

Location: Ann Arbor, Michigan

Posts: 4,214

Thanks: 143

Thanked 2,825 Times in 1,982 Posts

|

Quote:

Originally Posted by freebeard

I'm gathering parts for a 1Kw gravity vortex watermill. I've got a washing machine motor, a housing made from parts (a dog kennel and a ventilator!) and two outboard motor propellers to choose from (3-blade metal and 6-blade plastic). All I need now is a shaft to connect the propeller to the motor/generator and an optional extension tube that necks down from 14" to ~7".

Do you think it would be better to square the tips of the blades and put it in a duct, or leave the tips and put it below the end of the duct?

|

I don't know what I found humorous about your post as I haven't been drinking or anything, just didn't expect it.

I'm picturing something like the below.

Gravitation water vortex power plant

https://en.wikipedia.org/wiki/Gravit...ex_power_plant

Quote:

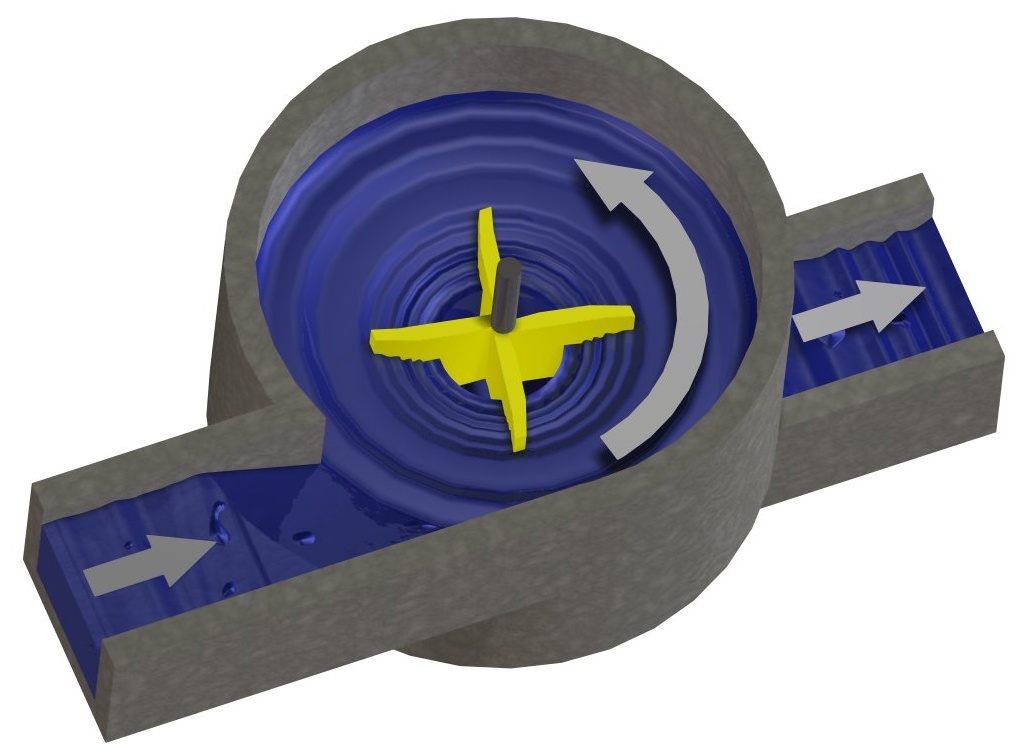

The gravitation water vortex power plant is a type of micro hydro vortex turbine system which is capable of converting energy in a moving fluid to rotational energy using a low hydraulic head of 0.7–3 metres (2 ft 4 in–9 ft 10 in). The technology is based on a round basin with a central drain. Above the drain the water forms a stable line vortex which drives a water turbine.

It was first patented by Greek-Australian Lawyer & Inventor Paul Kouris in 1996[1], who was searching for a way to harness the power inherent in a vortex.[dubious – discuss]

Later, Austrian Inventor Franz Zotlöterer created a similar turbine while attempting to find a way to aerate water without an external power source.[2]

|

My guess is that ducted systems are more efficient.

Ducted fan

https://en.wikipedia.org/wiki/Ducted_fan

Quote:

A ducted fan is a propulsion arrangement whereby a mechanical fan, which is a type of propeller, is mounted within a cylindrical shroud or duct. The duct reduces losses in thrust from the tips of the props, and varying the cross-section of the duct allows the designer to advantageously affect the velocity and pressure of the airflow according to Bernoulli's principle. Ducted fan propulsion is used in aircraft, airships, airboats,[dubious – discuss] hovercraft and fan packs.[1]

Ducted fans normally have more and shorter blades than conventional propellers and thus can operate at higher rotational speeds.[dubious – discuss]

|

Pump-jet

https://en.wikipedia.org/wiki/Pump-jet

Quote:

|

A pump-jet, hydrojet, or water jet is a marine system that creates a jet of water for propulsion. The mechanical arrangement may be a ducted propeller (axial-flow pump), a centrifugal pump, or a mixed flow pump which is a combination of both centrifugal and axial designs. The design also incorporates an intake to provide water to the pump and a nozzle to direct the flow of water out of the pump.[1]

|

Energy is going to squirt out the ends of the blade tips (right angles?) and will not be contained in the system if there is no containment duct. A bad thing in my opinion.

I'm just making this up as I go along, if anyone has direct experience please chime in. I've only messed with my hovercraft duct before.

EDIT: This looks to be pre-duct, not post duct or in-duct.

http://www.zotloeterer.com/welcome/g...-power-plants/

[IMG]http://www.zotloeterer.com/attachments/Image/GWVPP-OGRA-2014_1.jpg?template=generic[IMG]

Quote:

|

We will support you with consulting and planning and during project realisation.

|

__________________

George

Architect, Artist and Designer of Objects

2012 Infiniti G37X Coupe

1977 Porsche 911s Targa

1998 Chevy S-10 Pick-Up truck

1989 Scat II HP Hovercraft

You cannot sell aerodynamics in a can............

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

08-25-2018, 09:31 AM

08-25-2018, 09:31 AM

|

#72 (permalink)

|

|

Somewhat crazed

Join Date: Sep 2013

Location: 1826 miles WSW of Normal

Posts: 4,569

Thanks: 597

Thanked 1,254 Times in 1,106 Posts

|

I have messed with ducted fans before, and didn't notice an efficiency by squaring off the blades. Might be more efficient by leaving them full length, like high aspect ratio aircraft wings. Also On wind turbines, there is a trend towards longer not wider blades.

This is moot if your props are typical boat wide blade ones. My experience is in aircraft.

Actually your reference points towards a flat paddle set up like the motor in a die grinder

__________________

casual notes from the underground:There are some "experts" out there that in reality don't have a clue as to what they are doing.

|

|

|

|

|

The Following User Says Thank You to Piotrsko For This Useful Post:

|

|

08-25-2018, 11:39 AM

08-25-2018, 11:39 AM

|

#73 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,385

Thanks: 8,356

Thanked 9,123 Times in 7,533 Posts

|

Quote:

|

Originally Posted by kach22i

I don't know what I found humorous about your post as I haven't been drinking or anything, just didn't expect it.

|

Probably the idea of me doing anything other than typing comments .

This is the basis of it, turned upside down. I have friends that live upriver who have a year-round stream on their 100-year farm. I cut the hole in the top of the igloo before I found the propellers. I don't know if they're sized correctly for the motor/generator. I'll probably go to https://www.greenpowertalk.org for the math.

http://molotilo.com/wp-content/uploa.../igloo-dog.jpg

http://molotilo.com/wp-content/uploa.../igloo-dog.jpg[/I]

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.tragectory: Line goes down and to the right.

|

|

|

|

|

The Following User Says Thank You to freebeard For This Useful Post:

|

|

08-25-2018, 12:12 PM

08-25-2018, 12:12 PM

|

#74 (permalink)

|

|

Master EcoModder

Join Date: Jul 2010

Location: Belgium

Posts: 4,683

Thanks: 178

Thanked 653 Times in 516 Posts

|

Quote:

Originally Posted by freebeard

I have friends that live upriver who have a year-round stream on their 100-year farm.

|

I once read that the whole of the UK's electric power needs could be covered by harvesting the power of small streams & brooks ...

__________________

Strayed to the Dark Diesel Side

|

|

|

|

08-25-2018, 01:24 PM

08-25-2018, 01:24 PM

|

#75 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,385

Thanks: 8,356

Thanked 9,123 Times in 7,533 Posts

|

Probably true. This won't even cover their needs. It would be a test installation to access the flow year-round.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.tragectory: Line goes down and to the right.

|

|

|

|

08-25-2018, 10:30 PM

08-25-2018, 10:30 PM

|

#76 (permalink)

|

|

Master Novice

Join Date: Jan 2008

Location: SE USA - East Tennessee

Posts: 2,314

Thanks: 427

Thanked 617 Times in 451 Posts

|

The gravitation vortex thing looks like someone is trying to reinvent the Francis turbine and give it a different name.

__________________

Lead or follow. Either is fine.

|

|

|

|

08-26-2018, 10:39 AM

08-26-2018, 10:39 AM

|

#77 (permalink)

|

|

Master EcoModder

Join Date: Jul 2011

Location: Ann Arbor, Michigan

Posts: 4,214

Thanks: 143

Thanked 2,825 Times in 1,982 Posts

|

Quote:

Originally Posted by elhigh

The gravitation vortex thing looks like someone is trying to reinvent the Francis turbine and give it a different name.

|

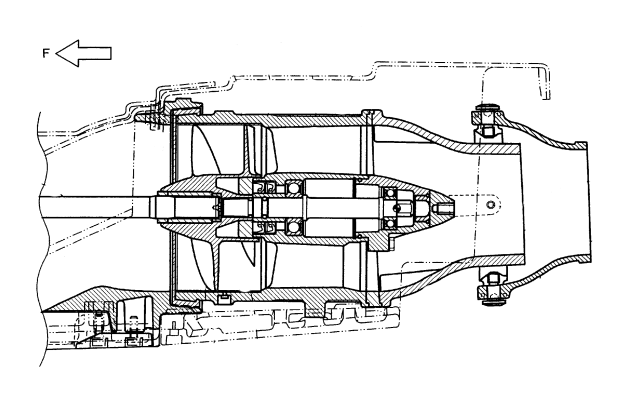

A sectional representation of the Francis in this video:

A 3D examination, some of terms were new to me.

Quote:

vancebarcelona

7 months ago

Francis turbines are the most preferred hydraulic turbines. It contributes about 60% of the global hydro power capacity mainly because it can work efficiently under wide range of operation conditions. The most important part of a Francis turbine is its runner. It is fitted with complex shade blades. In the runner, water enters radially and exits axially. During the course of flow, water goes through the runner blades. Francis turbine blades are specially shaped. We can note that blades are having thin airfoil cross section. So, when water flows over it, low pressure will be produced on one site and high pressure in the other site. This will result in a lift force. We can also note one more peculiar thing about the blade. It is having a bucket kind of shape towards the outlet. So, water will hit, and producing impulse force before leaving the runner. Both impulse force and lift force will make the runner rotate. So Francis turbine is not a pure reaction turbine. A portion of force come impulse action also. Thus, when water flows over runner blades, both its kinetic and pressure energy will come down. Since flow is entering radially and leaving axially, they are also called mixed flow turbine. Runner is connected to the generator via shaft for electricity production. This arrangement is fitted in a spiral casing. Flow enters via inlet nozzle. Flow rate of water will get reduced along length of casing, since water is drown into the runner. But decreasing area of spiral casing will make sure that water flow is entered to runner region almost at uniform velocity. Stay vanes and guide vanes are fitted at the entrance of runner. The basic purpose of them is to convert one part of pressure energy to kinetic energy. Flow which is coming from the casing meets stay vanes, they are fixed. Stay vanes steers the flow towards runner section. Thus, it reduces inlet flow. Demand for power changes over time. The guide vane mechanism is used to control flow rate and make sure that power production is synchronized with power demand. Apart from controlling flow rate, guide vanes also control flow angle to inlet portion of runner blade. Thus, guide vanes make sure inlet flow angle is the optimum angle of attack for maximum power extraction from fluid. Low pressure at the outlet of the turbine may cause serious problems of cavitation. So, a special draft tube is designed is fitted at exit site to discharge the fluid out. Draft tube will transform velocity head to static head due its increasing area that will reduce effect of cavitation.

|

There are differences that may not seem important to you or I, but to an engineer they probably make a great difference.

__________________

George

Architect, Artist and Designer of Objects

2012 Infiniti G37X Coupe

1977 Porsche 911s Targa

1998 Chevy S-10 Pick-Up truck

1989 Scat II HP Hovercraft

You cannot sell aerodynamics in a can............

|

|

|

|

08-26-2018, 12:01 PM

08-26-2018, 12:01 PM

|

#78 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,385

Thanks: 8,356

Thanked 9,123 Times in 7,533 Posts

|

My proposal most closely matches the 'gravitation water vortex' in Permalink #71. It is axial flow while the Francis turbine is centrifugal flow. What they do have in common is that the mechanical parts are completely above the flow of water.

I'm thinking about a pipe and shaft that is 4-6ft long, to gain from potential energy as well as the torque from rotating water column. That may not work because of added skin friction.

At 1hp it'd be a glorified water flow meter.

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.tragectory: Line goes down and to the right.

|

|

|

|

08-27-2018, 11:50 AM

08-27-2018, 11:50 AM

|

#79 (permalink)

|

|

Master EcoModder

Join Date: Jul 2011

Location: Ann Arbor, Michigan

Posts: 4,214

Thanks: 143

Thanked 2,825 Times in 1,982 Posts

|

Quote:

Originally Posted by freebeard

My proposal most closely matches the 'gravitation water vortex' in Permalink #71. It is axial flow while the Francis turbine is centrifugal flow...............

|

Yes, and as I understand it axial flow is normally more efficient.

At least was the case for the early British jet engines of Frank Whittle ( that did not use axial flow).

Go to about the middle of the page, I know this is apples to oranges comparison, but it's the best I can do for now.

https://en.wikipedia.org/wiki/History_of_the_jet_engine

Quote:

British aircraft engine designer, Frank Halford, working from Whittle's ideas, developed a "straight through" version of the centrifugal jet; his design became the de Havilland Goblin.

One problem with both of these early designs, which are called centrifugal-flow engines, was that the compressor worked by accelerating air outward from the central intake to the outer periphery of the engine, where the air was then compressed by a divergent duct set-up, converting its velocity into pressure.

|

It's the inherent redirecting energy at right angles that lowers the efficiency of centrifugal designs I do believe.

Some can argue that it's a trade off between velocity and pressure, but with water I don't think that's the case, as water is not compressible.

__________________

George

Architect, Artist and Designer of Objects

2012 Infiniti G37X Coupe

1977 Porsche 911s Targa

1998 Chevy S-10 Pick-Up truck

1989 Scat II HP Hovercraft

You cannot sell aerodynamics in a can............

|

|

|

|

08-27-2018, 02:52 PM

08-27-2018, 02:52 PM

|

#80 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,385

Thanks: 8,356

Thanked 9,123 Times in 7,533 Posts

|

Quote:

|

I know this is apples to oranges comparison, but it's the best I can do for now.

|

This isn't rocket science, just parts I pick up at the recyclers. I have an 18" diameter squirrel-cage fan with bronze bushings. At the bottom of a standpipe, it might be fit for purpose.

I could extend the downpipe and prop-shaft up to 6-8ft, I'm not sure the extra length would help or not. The skin friction might act against the rotation of the water column.

[can't find an aerodynamic oddity pic, posting anyway]

__________________

.

.Without freedom of speech we wouldn't know who all the idiots are. -- anonymous poster

___________________

.

.tragectory: Line goes down and to the right.

|

|

|

|

|