Quote:

Originally Posted by JSH

Ahh - random points from a picture. That makes sense now but those terms aren't anywhere near standard in the industry.

|

every major component manufacturer i've come across have used those as reference, including valeo, borg warner, eaton, dana, chevy, dodge, infineon, land rover, BMW, etc..

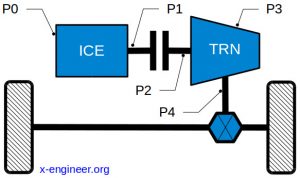

P0 is generally the starter/generator. P1 generally attaches either to, or between the flywheel and the transmission, P2 generally replaces the torque converter with a dual clutch electric motor, or, some manufacturers like kia and chevy put a separate electric motor inside the housing of the transmission, P3 is generally in the tail housing and P4 generally is adapted to, or, replaces the rear differential, but, technically would probably include some of the other setups like 2 individual motors for each rear wheel where there isn't a rear differential.

companies like infineon, valeo and SEG have controllers that are stand alone minus the input for throttle so the battery status and torque vectoring etc are already handled - if you can get one.

from what i've read so far, with the exception of the P2 motors that have clutches, the rest spin all the time, but, don't always regen because the windings aren't excited, and basically the regen control excites the windings to start the regen process, so, they don't seem to care about braking status, just battery status.

but as i say, i haven't really had any luck talking to anyone more familiar with the technology to learn more.

now i am kinda thinking about trying to find a 2009+ chevy hybrid to transplant wholesale into a express/savannah platform...