Almost all modern engines use offset crankshafts. The earliest one I'm aware of is the Insight engine, which may be why I know about it. Most Japanese engines moved to offset somewhere between 2008 and 2014 as part of a move to improve BSFC, because not only does it reduce stress, but it also reduces friction. It was basically the end of high RPM screamers, but extremely helpful in high compression turbo engines, which have exponentially more stress on the conrods, and more lateral force on the sidewalls. It redistributes forces, making the angles worse when the piston is moving upward (where it is essentially unloaded) and making them better at the point in reciprocation where forces are greatest. The greater the compression and cylinder pressure, the greater the "optimal" offset as far as stress is concerned, but relatively large offsets are almost always better for efficiency.

You can read what Yamaha wrote about it here:

https://global.yamaha-motor.com/desi...er_source/004/

Quote:

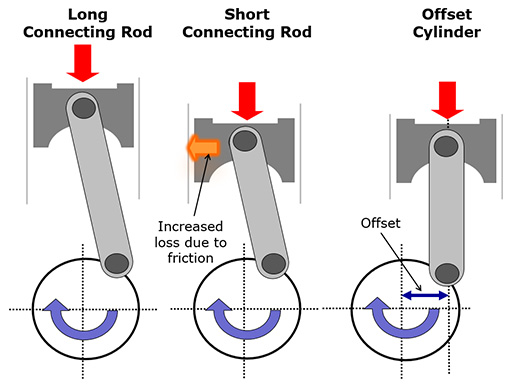

In general, the piston in an engine is pushed down by the explosive force of combustion in the combustion chamber and this is the origin of the drive force created by an engine. Strictly speaking, however, the piston is not actually pushed straight downward. Although it is small, there is in fact a diagonal component to the downward force that causes the piston to be pushed against the wall of the cylinder. This results in friction and a corresponding amount of horsepower loss. This friction-induced power loss can be reduced by lengthening the connecting rod, but lengthening the rod makes the engine heavier and larger overall.

The offset cylinder is a design that solves both of these inherently conflicting problems. This is accomplished by “offsetting” the cylinder from the crankshaft so that the axis of the piston and connecting rod are aligned vertically at the moment of combustion—when the pressure in the cylinder is at its peak. Doing this greatly reduces the friction from the diagonal force pushing the piston against the cylinder wall. At the same time, this enables more effective use of the energy produced by combustion. The engine in the F2.5A has a bore × stroke of 54 mm × 31.5 mm. The cylinder offset was set at a large 10 mm, increasing combustion efficiency and enabling a more compact design at the same time (#3).

In the offset cylinder design, the amount of offset affects the fuel efficiency, power output, engine response and more. Yamaha’s waza lies in determining the optimal amount of offset during development in line with the model’s characteristics.

Increasing the length of the connecting rod reduces the amount of friction between the piston and the cylinder wall, but it also makes the engine bigger (left). A shorter connecting rod produces more friction loss (center). The offset cylinder (right) enables both reduced loss and a more compact design.

|