09-10-2015, 11:13 PM

09-10-2015, 11:13 PM

|

#11 (permalink)

|

|

Carbon Abuser

Join Date: Sep 2015

Location: Texas

Posts: 78

Olaf - '03 Honda Civic Hybrid Sven - '06 Volvo Xc90 2.5t Work Truck - '04 Chevy Silverado 3500

Thanks: 0

Thanked 16 Times in 13 Posts

|

I need to shy from anything that could possibly damage the buildings. The other issue is the varied sizes and shapes i haul. From 8-16' wide, and 8-12' tall.

My thought on side skirts is toolbox back, tucked under the edge rail of the bed. I may have to get creative about tying into the back of the bed because of its taper. Then i need to tackle the front of the toolboxes.

My main concern is unloaded economy. The truck does a lot of just running around empty, and most moves/deliveries i do don't require the trailer, so alot of empty miles to and from.

The trailer does not have a solid deck, it is rollers and pipe. Would side fairings really net any gain without the solid floor? Other issue is it tilts on the back axle when unloading, and the tail usually sets on the ground. I will get more pics when I am back at work next week.

I am not trying to be negative Nelly, and i hope guys taking it that way. I am just trying to weigh how things would function with how i use the truck.

So here are some photos...

Hauling a 10x22x7 barn.

12x16x7 Barn

12x20x7 Peak

16x24ish on the trailer

__________________

1986 Chevy C-10 10mpg Grandpa's Truck

2004 Chevy 3500 diesel 10mpg The work Truck

2003 Honda Civic Hybrid 5 spd ?? Mpg My Carbon Pentance

|

|

|

|

Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

09-11-2015, 02:02 AM

09-11-2015, 02:02 AM

|

#12 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,278

Thanks: 8,327

Thanked 9,078 Times in 7,501 Posts

|

Looks like your best bet would be more aerodynamic barns.  |

|

|

|

09-11-2015, 03:54 AM

09-11-2015, 03:54 AM

|

#13 (permalink)

|

|

(:

Join Date: Jan 2008

Location: up north

Posts: 12,762

Thanks: 1,585

Thanked 3,556 Times in 2,218 Posts

|

This must be just about the worst case scenario there can be.

Pull the mirrors off when empty and go slow (<55) realizing that without serious fabrication and effort, this thing is simply an aero disaster.

|

|

|

|

09-11-2015, 07:42 AM

09-11-2015, 07:42 AM

|

#14 (permalink)

|

|

Carbon Abuser

Join Date: Sep 2015

Location: Texas

Posts: 78

Olaf - '03 Honda Civic Hybrid Sven - '06 Volvo Xc90 2.5t Work Truck - '04 Chevy Silverado 3500

Thanks: 0

Thanked 16 Times in 13 Posts

|

Yes, it is def not ideal, to say the least. I know slowing down would help. The good news is when i am loaded i dont have to watch all the idiots fly up and almost eat my hind portions. I honestly don't even know what the thing does fuel wise, i need to check it. One thing that really hurts it is LOTS of idle time. When I am loading or unloading it is running. Gotta keep the batteries charged up to power the 12k lb winch, it can sure zap them in a hurry. Of course you have also extended warm up times in winter, cool down in summer. It really is an mpg nightmare.

__________________

1986 Chevy C-10 10mpg Grandpa's Truck

2004 Chevy 3500 diesel 10mpg The work Truck

2003 Honda Civic Hybrid 5 spd ?? Mpg My Carbon Pentance

|

|

|

|

09-11-2015, 11:55 AM

09-11-2015, 11:55 AM

|

#15 (permalink)

|

|

EcoModding Lurker

Join Date: Jul 2014

Location: Laurel, MD

Posts: 44

Thanks: 1

Thanked 14 Times in 10 Posts

|

I don't usually post, but I was thinking about this and had an idea how you could do an aerolid. First, cut a sheet of plywood to shape and attach it to the bed side of the metal hoop behind the cab so no air can get through. I don't know how long your bed is so I'm assuming 8' but adjust as needed. Take a flat sheet of plywood and attach with hinges to the top of the metal hoop so it can swing from below horizontal with the far end touching the bed by the back bumper, up to vertical. Make the back end something like 2' narrower than the front end to give 5-10 degrees of plan taper - the exact dimensions obviously depend on the bed and lid length and others will have to recommend the optimum target angles. Take a piece of 8" pvc pipe and rip it lengthwise into four 90 degree quadrants, and attach one quadrant across the back end of the lid. For an 8' bed and 2' high metal frame that should give about 12 degrees of downslope, which is in the range of 10-16 degrees that I've seen recommended here. Cut trapezoidal pieces of plywood to connect the front edge along the metal frame, the top edge along the lid, the bottom edge along the outside of the sides of the bed, and the back end where the pvc pipe is. Probably best to attach quarter discs to cover the ends of the pipe section to the pipe, and then have a straight edge on the side pieces. Attach the sides to the lid with hinges, add some kind of latch or bracket to attach the back edge of the side pieces to the ends of the pvc pipe, and some kind of latch or strap to hold it down in the back. Now you have an aerolid for cruising empty.

Attach two vertical pieces of say 3.5 or 4" iron pipe as tall as the metal frame, about 6-12" in from each side, flip the lid so it is standing up vertically, and drop two pieces of 3" iron pipe into the sockets and attach the lid to the pipes with some kind of loops or clamps to support it in this position, and now you have a front wall that can take a moderate wind load and can load your buildings onto the bed. Either fold the side pieces in so the pipes hold them in the folded position, or fold them out and add horizontal bars to support them so they cover more of the front of the building. Ideally, if the bed length and the height of your cargo match, the pvc pipe will give you a nice rounded edge across the top. If the lid comes out way too tall then you will either have to make a horizontal cut and add more hinges so you can fold it as you raise it, or make the lid shorter than the bed.

If you added horizontal supports to let the side flaps fold outward, you can add vertical pieces of the 8" pvc quadrants on horizontal bars that connect to those supports, and make the horizontal bars in different lengths to match 8', 10', and 12' buildings. This will give rounded vertical corners for even better aerodynamics.

After you build the wood version and test it, get one of those bulbous nose plastic bulges that they sell to go on the front of trailers, and attach it to the lid so the bottom of the bulge is as close to the cab roof as possible. This should help when you have a building on the bed, and may help or may hurt when the lid is down, it depends on how steep the side angles get and you will just have to test. Measure the bed length, the height of the metal frame at the front, and the most common building heigth and see how the angles work out, and build the simple plywood lid first for testing, then you can add the pvc edges and front bulge if you want to keep going. I don't know what to do about the openings in the bed - can you add a belly pan below the rollers and tilt mechanism? Don't worry so much about the idling time, that's where diesels excel compared to a gasoline engine.

Anyway, just one possible design you could pursue.

__________________

Regards,

Carl Ijames carl.ijames xx@xx verizon.net delete the xxs

|

|

|

|

09-11-2015, 02:54 PM

09-11-2015, 02:54 PM

|

#16 (permalink)

|

|

Carbon Abuser

Join Date: Sep 2015

Location: Texas

Posts: 78

Olaf - '03 Honda Civic Hybrid Sven - '06 Volvo Xc90 2.5t Work Truck - '04 Chevy Silverado 3500

Thanks: 0

Thanked 16 Times in 13 Posts

|

The bed is 12' long. It is going to take a minute to digest all of your post....trying to paint the picture in my head.

__________________

1986 Chevy C-10 10mpg Grandpa's Truck

2004 Chevy 3500 diesel 10mpg The work Truck

2003 Honda Civic Hybrid 5 spd ?? Mpg My Carbon Pentance

|

|

|

|

09-11-2015, 04:53 PM

09-11-2015, 04:53 PM

|

#17 (permalink)

|

|

Master EcoModder

Join Date: Jan 2008

Location: Sanger,Texas,U.S.A.

Posts: 16,470

Thanks: 24,498

Thanked 7,431 Times in 4,814 Posts

|

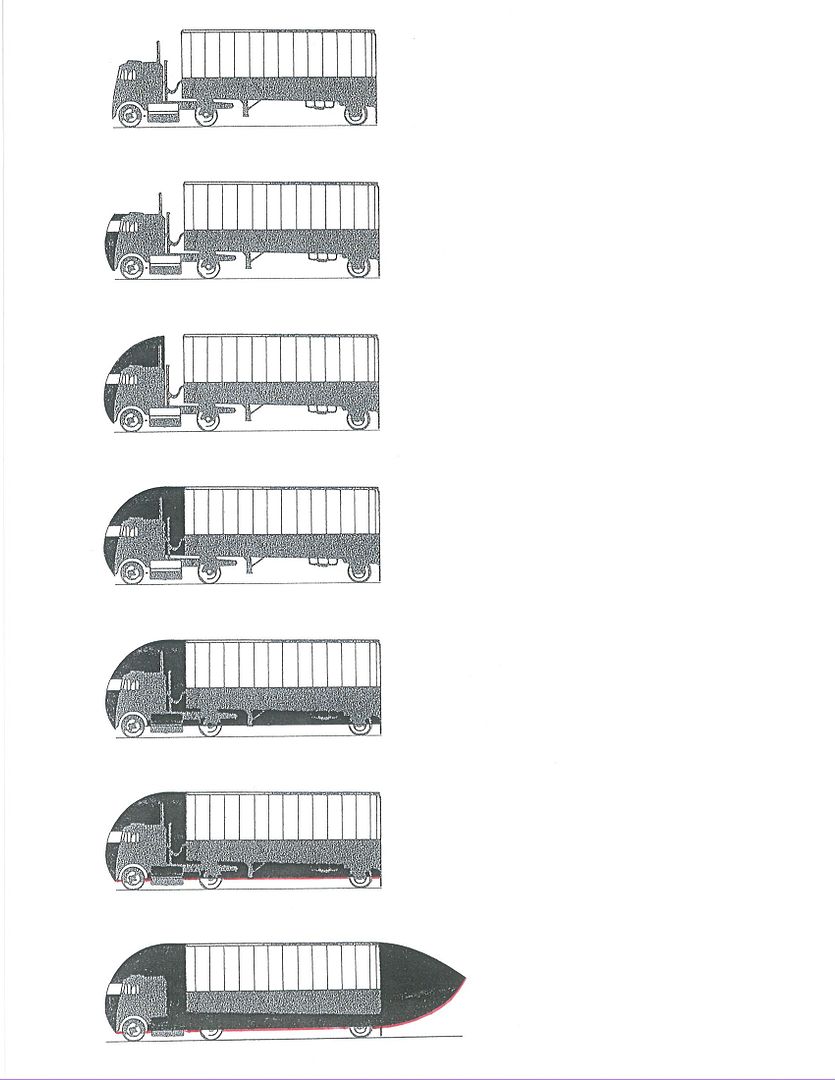

towing buildings

If I was gonna do this for a living,I'd:

* lose the rig

*buy a Class-7 bob-tail turbo-diesel tractor

*and pull a 5th-wheel low-boy trailer, with the load hugging the ground, rear axles behind and above the trailer floor.

*this would reduce frontal area

*get the center of gravity down

*then construct some adaptive,multi-purpose nose fairing which could be taken down after each delivery.

*or fashion a cushioned inflatable airbag which could be strapped to the buildings nose for the trip,then unstrapped upon delivery.

--------------------------------------------------------------------------

*the tractor could be optimized independent of the loads

*the loads are where the major drag is

*the buildings are around Cd 0.88

*softening their nose could get them to Cd 0.45 or so

---------------------------------------------------------------------

*technically,the tractor should be just as large as the building your pulling

*and no gap in between

Here's what NASA did to their semi-trailer

__________________

Photobucket album: http://s1271.photobucket.com/albums/jj622/aerohead2/

|

|

|

|

|

The Following User Says Thank You to aerohead For This Useful Post:

|

|

09-11-2015, 06:09 PM

09-11-2015, 06:09 PM

|

#18 (permalink)

|

|

EcoModding Lurker

Join Date: Jul 2014

Location: Laurel, MD

Posts: 44

Thanks: 1

Thanked 14 Times in 10 Posts

|

Well if the bed is 12' long then you could make the aerolid in two sections so when you stand them up in front of the building they are a reasonable height. See what aerohead says, but you could have the first section angle gently at say 3-6 degrees for 5' since the front of that is attached to hinges to the top of the metal hoop so when you stand it up it will be about 2'+5'=7' so it just covers your building cargo, then have the second section angle at 12-15 degrees for 7' so when it is vertical it goes from the bed up to the top of the front section. Either have the two pieces joined with a hinge or have them join with something like hasps and clevis pins.

The way to think of the aerolid design is as a box with angled top and narrower at the rear of the bed than the front, with side panel and an end plate (either flat or the pvc pipe idea), then when you need to carry cargo you flip the box vertical to expose the bed for cargo and to form a wall in front of the cargo that you can add rounded top and sides to.

__________________

Regards,

Carl Ijames carl.ijames xx@xx verizon.net delete the xxs

|

|

|

|

09-11-2015, 06:42 PM

09-11-2015, 06:42 PM

|

#19 (permalink)

|

|

Carbon Abuser

Join Date: Sep 2015

Location: Texas

Posts: 78

Olaf - '03 Honda Civic Hybrid Sven - '06 Volvo Xc90 2.5t Work Truck - '04 Chevy Silverado 3500

Thanks: 0

Thanked 16 Times in 13 Posts

|

So, the next portion, I have to be able to get into and out of peoples yards to deliver the buildings, thus loading them on the truck itself when possible. Sometimes I will haul the building on the trailer and then pull it onto the truck to set the building. Plus going to a tractor like that puts us in another class with DOT and our requirements go crazy. I have a CDL so I can legally drive one, but once get a rig that grosses over 26k things get alot more difficult and expensive. Now at some point we may go to a tractor for hauling our buildings from our manufacturer, but it is overkill on almost all of our deliveries.

The flat deck trailer, while not the best aero option, is the best business option. On a low boy with the axles up and behind the load, you greatly reduce capacity. Trailer length is limited by DOT to 53' without needing a permit every time you have it on the road. So with the axles set up like that you loose that much footage of carrying, unless a smaller building could be set on top of them. The other manipulation the flat deck allows is rear overhang. You can put over 50' of buildings on a 50' trailer because, depending on the building size, you could run with 6-8' of rear overhang.

My primary thought still lies with what I can do to improve empty, unloaded mileage on the pulling unit itself.

__________________

1986 Chevy C-10 10mpg Grandpa's Truck

2004 Chevy 3500 diesel 10mpg The work Truck

2003 Honda Civic Hybrid 5 spd ?? Mpg My Carbon Pentance

|

|

|

|

09-11-2015, 07:31 PM

09-11-2015, 07:31 PM

|

#20 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,278

Thanks: 8,327

Thanked 9,078 Times in 7,501 Posts

|

Word Count Tool - A Free Word Counter

Permalink #15: 735 words

Permalink #: 211 words

Almost worth a picture.

Howzabout : A telescoping mast in the headache rack with a 2nd hand cab deflector off one of the big boy trucks. It's fitted as an aerolid behind the cab, but will raise and rotate 180° to it's 'normal' location.

Edit: Plus: A free sunvisor.

Last edited by freebeard; 09-11-2015 at 07:40 PM..

|

|

|

|

|