Today Today

|

|

|

|

Other popular topics in this forum...

Other popular topics in this forum...

|

|

|

|

03-12-2016, 06:04 PM

03-12-2016, 06:04 PM

|

#2 (permalink)

|

|

Eco-ventor

Join Date: Oct 2010

Location: sweden

Posts: 1,647

Thanks: 77

Thanked 713 Times in 452 Posts

|

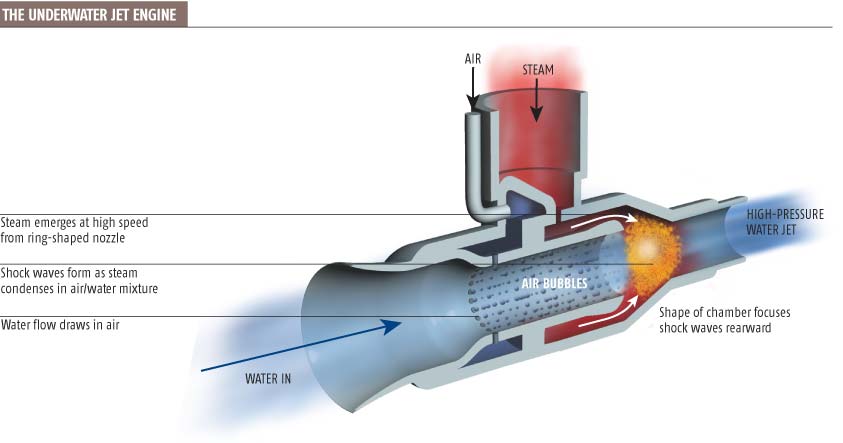

Reminds me of this:

__________________

2016: 128.75L for 1875.00km => 6.87L/100km (34.3MPG US)

2017: 209.14L for 4244.00km => 4.93L/100km (47.7MPG US)

|

|

|

|

03-13-2016, 12:58 PM

03-13-2016, 12:58 PM

|

#3 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,308

Thanks: 8,336

Thanked 9,094 Times in 7,511 Posts

|

In the mountains, too. I think it's for water.

jakobnev -- Another drawing. I wonder what the air input is for. Do you know if that was constructed or tested?

|

|

|

|

03-13-2016, 04:32 PM

03-13-2016, 04:32 PM

|

#4 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,308

Thanks: 8,336

Thanked 9,094 Times in 7,511 Posts

|

...or a ram jet that uses steam instead of combustion to expand the exhaust.

|

|

|

|

03-17-2016, 02:50 PM

03-17-2016, 02:50 PM

|

#5 (permalink)

|

|

Karmann Eclectric

Join Date: Feb 2010

Location: Graham, WA

Posts: 165

Thanks: 9

Thanked 90 Times in 51 Posts

|

Steamrollin

With all the idiots 'rollin coal' around my neck of the woods in their absurd trucks, I'd like to reciprocate with an enhancement to my sensible, stock-height grandpa truck ('87 F250 IDI 6.9 Liter).

Anybody explored water injection into the exhaust for brief but billowing clouds of steam? I'm thinking that sure, it'd increase back pressure and actually hurt performance during use, but not enough to damage anything if done judiciously.

Initial idea is to weld in a bung to the steel downpipe after the exhaust manifold, keeping the manifold nice n hot and avoiding any thermal shock to the cast iron, using a water/methanol injection nozzle and pump on a momentary switch.

Having a valve and controller to use water injection for economy or occasional steamrollin would be even more fun.

__________________

2012 Mitsubishi i-MiEV, 112 MPGe

2000 Honda Odyssey

1987 F250 Diesel, 6.9L IDI, goes on anything greasy

1983 Grumman Kurbwatt, 170 kW "Gone Postal" twin

1983 Mazda RX-7 electric, 48 kW car show cruiser

1971 VW Karmann Ghia electric, 300 kW tire-smoker

1965 VW Karmann Ghia cabriolet, 1600cc

Have driven over 100,000 all-electric miles!

|

|

|

|

03-17-2016, 09:34 PM

03-17-2016, 09:34 PM

|

#6 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,308

Thanks: 8,336

Thanked 9,094 Times in 7,511 Posts

|

Couldn't it be in the tailpipe tip, to reduce corrosion upstream?

And what's the methanol for, anti-freeze?

|

|

|

|

03-18-2016, 04:06 PM

03-18-2016, 04:06 PM

|

#7 (permalink)

|

|

Not Doug

Join Date: Jun 2012

Location: Show Low, AZ

Posts: 12,301

Thanks: 7,306

Thanked 2,244 Times in 1,732 Posts

|

Here I was thinking into adding a bubble blower to my exhaust.

|

|

|

|

03-18-2016, 09:30 PM

03-18-2016, 09:30 PM

|

#8 (permalink)

|

|

Master EcoModder

Join Date: Aug 2012

Location: northwest of normal

Posts: 29,308

Thanks: 8,336

Thanked 9,094 Times in 7,511 Posts

|

Salem, OR used to have city buses called Cherriots that had (maybe still do) diesel exhaust that smelled like cherries. |

|

|

|

|

The Following User Says Thank You to freebeard For This Useful Post:

|

|

03-23-2016, 08:19 PM

03-23-2016, 08:19 PM

|

#9 (permalink)

|

|

Karmann Eclectric

Join Date: Feb 2010

Location: Graham, WA

Posts: 165

Thanks: 9

Thanked 90 Times in 51 Posts

|

Quote:

Originally Posted by freebeard

Couldn't it be in the tailpipe tip, to reduce corrosion upstream?

And what's the methanol for, anti-freeze?

|

No methanol, just running water through the weld-on injectors sold for methanol/water injection on intake manifolds.

I proposed placing the injectors 'high' in the exhaust system to get maximum vaporization via dwell time, turbulence, and the built up heat in steel pipes. I'm not worried about excess corrosion. After all, there's already a lot of water vapor in exhaust, and this is only something that will work after warmup. As long as one doesn't get the exhaust system all wet right before shutdown, why would it matter? I'd expect that soot removal from the steaming would be pretty effective.

That being said, this would be most effective in winter, and exhaust tip injection might be the only way to make the steam visible for more than a second in summer.

__________________

2012 Mitsubishi i-MiEV, 112 MPGe

2000 Honda Odyssey

1987 F250 Diesel, 6.9L IDI, goes on anything greasy

1983 Grumman Kurbwatt, 170 kW "Gone Postal" twin

1983 Mazda RX-7 electric, 48 kW car show cruiser

1971 VW Karmann Ghia electric, 300 kW tire-smoker

1965 VW Karmann Ghia cabriolet, 1600cc

Have driven over 100,000 all-electric miles!

|

|

|

|

05-08-2016, 05:23 PM

05-08-2016, 05:23 PM

|

#10 (permalink)

|

|

EcoModding Lurker

Join Date: Feb 2012

Location: Houston

Posts: 80

Thanks: 24

Thanked 19 Times in 12 Posts

|

Quote:

Originally Posted by jray3

With all the idiots 'rollin coal' around my neck of the woods in their absurd trucks, I'd like to reciprocate with an enhancement to my sensible, stock-height grandpa truck ('87 F250 IDI 6.9 Liter).

…

Initial idea is to weld in a bung to the steel downpipe after the exhaust manifold, keeping the manifold nice n hot and avoiding any thermal shock to the cast iron, using a water/methanol injection nozzle and pump on a momentary switch.

Having a valve and controller to use water injection for economy or occasional steamrollin would be even more fun. |

I think you're on to something here. I've read in other gas engines where exhaust water injection is used to create a reflective wave which dynamically "tunes" the exhaust system (via exhaust gas scavenging) to improve torque and horsepower at rpm bands other than what the original system was designed for. May be kind of a nice thing when you're pulling a stock trailer vs. putzing about town.

I don't see that a large amount of water would be needed, just enough to reflect the exhaust pulse. And I doubt enough energy would be absorbed to change the temperature of the iron manifold in any significant way.

Further, on a turbo set up it may be a nice way to keep the turbine de-coked.

|

|

|

|

|